Cosmetic tubes are hygienic and convenient to use. The surface is colorful, bright and beautiful. They are economical, convenient and easy to carry. Even if they are squeezed with high intensity, they can still return to their original shape and maintain a good appearance. Therefore, they have been widely used in the packaging of cream cosmetics, such as the packaging of facial cleanser, conditioner, hair dye, toothpaste and other products in the cosmetics industry, as well as the packaging of topical drugs such as creams and ointments in the pharmaceutical industry.

1. Soft tubes include and material classification

Cosmetic soft tubes generally include

*Tube + outer cover. The tube body is often made of PE plastic. There are also aluminum-plastic tubes, all-aluminum tubes, and environmentally friendly paper-plastic tubes.

*All-plastic Soft tubes: The entire tube is made of PE material. Pull out the tube first and then perform cutting, offset printing, silk screen printing, and hot stamping. According to the tube head, it can be divided into round tube, flat tube and oval tube. Tail sealing can be divided into straight grain tail sealing, diagonal grain tail sealing, heterosexual tail sealing, etc.

*Aluminum plastic soft tubes

Two layers inside and outside, the inside is made of PE material, and the outside is made of aluminum packaging and then rolled. According to the tube head, it can be divided into round tube, flat tube and oval tube. Tail sealing can be divided into straight grain tail sealing, diagonal grain tail sealing, heterosexual tail sealing, etc.

*Pure aluminum tube: pure aluminum material, recyclable and environmentally friendly. The disadvantage is that it is easy to deform, as you can see from the toothpaste tubes that were common before the 1980s. But it is relatively unique and easy to create memory points. The most typical one is the aluminum tube packaging material of Aesop Skin Care.

2. Classification by product thickness

According to the thickness of the tube, it can be divided into single-layer tube, double-layer tube and five-layer tube, which are different in terms of pressure prevention, anti-penetration and feel. Single-layer pipes will be thinner; double-layer pipes are more commonly used; five-layer pipes are high-end products, consisting of an outer layer, an inner layer, two adhesive layers, and a barrier layer. Features: It has excellent gas barrier properties, which can effectively prevent the penetration of oxygen and odor gases, while preventing the fragrance and active ingredients of the content from leaking out.

3. Classification according to tube shape

According to the tube shape, it can be divided into: round tube, oval tube, flat tube, super flat tube, etc.

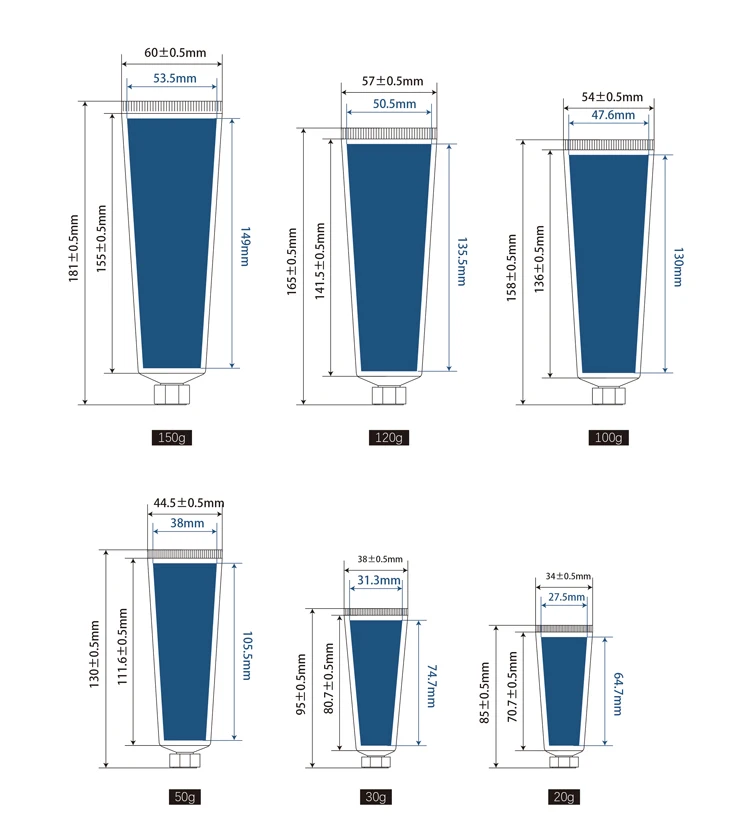

4. Caliber and height of Soft tubes

The tube diameters range from 13# to 60#. When a tube of a certain caliber is selected, different lengths are used to indicate different capacity characteristics. The capacity can be adjusted from 3ml to 360ml. For the sake of beauty and coordination, 35# is commonly used below 60ml. For the following calibers, 100ml and 150ml usually use 35#-45# caliber, and for capacities above 150ml, 45# or above are required.

5. Soft tubes caps

Tube caps come in various shapes, generally divided into flat caps, round caps, high caps, flip caps, ultra-flat caps, double-layer caps, spherical caps, lipstick caps, plastic caps can also be processed in a variety of processes, including hot stamping edges, silver Edge, colored cover, transparent, oil spray, electroplating, etc. The tip cover and lipstick cover are usually equipped with an inner plug. The caps are injection molded and the tubes are drawn tubes. Most tube manufacturers do not produce tube caps themselves.

6. Production process

•Bottle body

The tube can be made into colored tube, transparent tube, colored or transparent frosted tube, pearlescent tube, and can be divided into matte and glossy. Matte looks elegant but is easy to get dirty. The color of the tube body can be directly added to the production of plastic products, and some can be printed on a large area. The difference between colored tubes and large-area printing on the tube body can be judged from the incision at the tail. The tube with a white incision is a large-area printed tube. The ink requirements are high, otherwise it will easily fall off and will crack and reveal white marks after being folded.

•Bottle printing

Silk screen printing (using spot colors, small and few color blocks, the same as plastic bottle printing, requiring color registration, commonly used in professional line products) and offset printing (similar to paper printing, large color blocks and many colors) , commonly used in daily chemical line products.), as well as hot stamping and hot silver.

7. Soft tubes production cycle and minimum order quantity

Generally, the cycle time is 15 to 20 days (from the time of confirming the sample tube). The order quantity of a single product is 5,000 to 10,000. Large-scale manufacturers usually set a minimum order quantity of 10,000. Very few small manufacturers have a large number of varieties. The minimum order quantity of 3,000 per product is also acceptable. Very few customers open molds by themselves. Most of them are public molds (a few special lids are private molds). The contract order quantity and the actual supply quantity are ±10 in this industry. % deviation.

8. Price and printing fee

There is a big difference in price between tube quality and manufacturer. The plate making fee is usually 100-200 US dollars. The tube body can be printed with multi-color printing and silk screen. Some manufacturers have thermal transfer printing equipment and technology. Hot stamping and silver hot stamping are calculated based on unit price per area. Silk screen printing has better effect but is more expensive and there are fewer manufacturers. Different manufacturers should be selected according to different levels of needs.