Senior cosmetic product or supply chain departments know that more than half of the cosmetic OEM processing, more than half of the problems will appear in the packaging, and even more packaging failure loss irreparable.

Cosmetic packages including:inner packages (containers) + outer packaging + packaging design + product copywriting. Each part is the responsibility of a specialized department. Packaging by the procurement staff docking, design by the cosmetic industry design design, product copywriting by the filing department and planning department to complete, visible package is particularly important.

Packaging is very diverse, such as a variety of shapes and specifications of plastic bottles, plastic bags of composite film bags; glass bottles, jars, including wide-mouth bottles and narrow-mouth bottles, generally used for higher-grade cosmetics or volatile, easy to penetrate, containing organic solvents in the packaging of cosmetics, like hair dyes, perfumes, toners and so on. There are also many forms of outer packaging, such as color printing and other processes of cartons, plastic boxes.

The difference between graphic design and industrial design is that the ideal is perfect, and in reality there is a lot to consider, such as money, whether the production equipment can meet the mass production, and whether the quality of the product can be guaranteed.

Examples of the characteristics of various inner packaging containers

1. Glass bottles and jars: the advantages and disadvantages of glass materials are equally obvious, weight, easy to break, easy to scratch; physical and chemical properties are stable, cheap and eco-friendly, can be recycled and reused. For volatile, easy to lose the flavor of cosmetics can be packaged in glass. Perfume is the most is the use of glass bottles, looks high-end, the fragrance to maintain the best.

Plastic: The advancement of science and technology has enabled many shortcomings of plastic to be solved. Some packaging materials have a technological feel and the product texture can also be produced. At present, many plastics are easy to scratch, which makes them uncomfortable during production, transportation and use. Scratch-resistant materials are usually more expensive. The price range of plastic is relatively large, and the minimum order quantity is much higher than that of glass. Many design ideas can be realized, but you must consider whether the brand can accept it.

Acrylic is a type of plexiglass, which can generally be considered a plastic. Acrylic molding is expensive, often requiring thousands of dollars in printing fees.

Packaging design is a comprehensive issue, which involves many aspects of knowledge such as material use, molding process, technical structure, artistic vision, creativity, product technology and consumer psychology. As a packaging designer or developer, you must understand the commonly used packaging materials, packaging performance characteristics, be familiar with packaging container forming methods and processing techniques, and master the technical structure design and artistic modeling design methods of packaging containers.

Excellent appearance ideas will be limited by materials, structures, processes and other conditions and cannot be realized, or the actual processing cost will be significantly increased, or the produced product packaging cannot be filled on the production line, or the processing is too difficult to scale. Production. As a designer, we must be able to fully consider the use environment, circulation links and compatibility with products during the packaging design process, and on this basis, scientifically design the packaging container in terms of shape design, structure design, material design and manufacturing process design. Comprehensive design verification means.

So how do you design a good product? Basically three conditions must be met

1. Functional utility is the starting point of container shape design. It includes storage function, convenience function, sales function, psychological value function, ease of transportation, etc. These requirements are constantly summarized in the shape design experience.

2. Material technology. This is the basic means to complete the design. It not only limits function and shape, but also serves function and shape with its unique superiority. In design, we must learn to select materials and processes based on function and cost, and we must constantly look for new materials to meet design needs.

3. Styling image. On the basis of ensuring ease of use, packaging and transportation, the appearance is as creative and innovative as possible, integrating art, fashion, technology, culture and other elements into it. These require designers to have a deep accumulation of basic skills such as plastic arts, style, color, and layout.

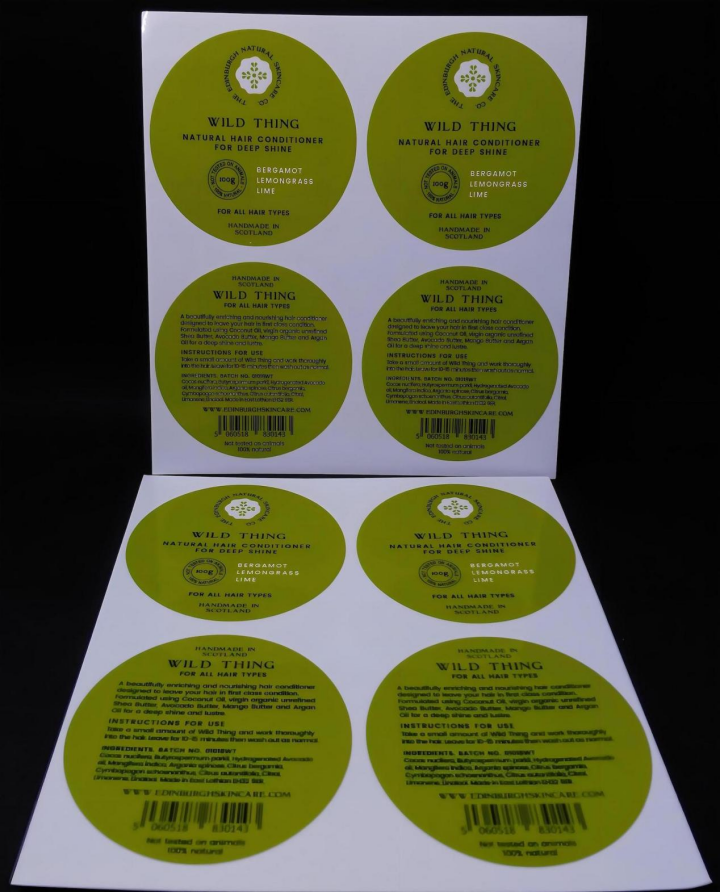

Cosmetic packagings are not just containers, but also include outer packaging boxes, inner cartons, labels and some auxiliary tools. In particular, packaging for skin care products vary greatly due to different materials and shapes. Therefore, in OEM production and processing, the selection of packaging is very important. Good packaging can enhance the image and quality, and are “eye-catching”. When customers determine the OEM production and processing manufacturer, they must attach great importance to the purchase of packaging and track the production process to "pre-research the market, predict the process, and pre-control risks" to ensure that "the quality is guaranteed and the construction period can be on time." , the service is excellent.”

Specifically, it is to control five aspects:

First, whether the design is reasonable. As an OEM customer, in considering the cost at the same time, should consider the market expectations, control the package design gate, from the outer box to the inner carton; from the container form to the label copy; from the style of the positioning to the transportation risk; from the inner package to the outsourcing, etc., the whole picture, the overall arrangement, to ensure that the structure is reasonable, physical good. Some customers only consider the container, and the outsourcing and other aspects of the hands, especially the geographical situation, transportation, etc., not integrated, resulting in a good product without a good appearance, and ultimately harm the overall image of the product, damage to the interests of the customer.

Second, whether the capacity is standardized. Skin care packages are many kinds of materials, the production process is more complex, sometimes it is inevitable that there is a gap between the capacity of the container and the design standard, therefore, before the container production, it should fully consider the characteristics of the material body, targeted control. Whether the special specifications are complete, whether the shape is beautiful, whether the visual comfort, and so on. Many customers in the negotiation of business, often only know in accordance with the sample production, in fact, this is not rigorous, because the material body is different, the same container with the net content is different.

Third, whether the text is standardized. Many countries are very strict management of cosmetic labeling, must be strictly in accordance with the standards, especially efficacy products, some ingredients and their indicators can not have half a mistake and discrepancies, otherwise, even the best package can not be used. Also, in the efficacy of the product, it must be carefully scrutinized, carefully reviewed to avoid false content, to avoid prohibited words, to avoid consumer ambiguity.

Fourth, the pass rate and moderate over-purchasing. Cosmetic packaging materials, especially the outer packaging materials are hand-produced, such as cartons, handbags, and so on, due to the low degree of automation, it is inevitable that there will be defective products or defective products. Some machine-produced glass bottles, tubes, etc. in the color difference, leakage of prints, morphology, etc., there will also be this and that problem, therefore, when shopping, these issues should be considered. If the package material inspection, the ratio of qualified and defective products does not exceed the basic standards, then the package purchase is successful, but when ordering packages, the number should be increased appropriately to ensure that there is enough amount for selection.

The last point: cosmetic package content filing needs attention:

Review of the contents of the package on the label

1. Product name in line with the cosmetic naming rules.

2. Can not appear national banned words, such as marijuana, drug substitution and other words.

3. The commissioning party and the commissioned party need to be labeled with the full name as well as the address.

4. The origin labeling format is in line with the target market standards.

5. Shelf life of the two correct labeling, a production date + shelf life, b production lot number + limit date.

6. Ingredient labeling in accordance with the regulations.

Packaging material appearance inspection

1. All printed copy on the packaging is consistent with the sample copy, and there are no typos or omissions.

2. There is no obvious color difference in the single color of packaging materials from the same batch, and the color printing is not rough.

3. The surface of the packaging material is smooth, flat, clean, without wrinkles, roughness, unevenness, or obvious scratches or abrasions.

4. There is no glue spillage on packaging materials that use glue.

5. There are no exposed corners or edges around the packaging material.

6. The length of the suction tube of the pump head is appropriate; the incision is standardized.

Functional testing

1. The size and material are consistent with the sample.

2. The full mouth capacity is greater than or equal to the labeled amount.

3. All packaging accessories are complete and suitable.

4. Carry out sealing test, and there will be no leakage when tested by vacuum method or inversion method.

5. Screen printing, spraying, ink, and wiping methods show no peeling, discoloration, or peeling.

6. The pump bottle and spray bottle have been air-pressured 200 times without damage or failure.