There’s something almost poetic about the journey cosmetic packaging is taking right now. The global cosmetic packaging market, valued at $57.55 billion in 2025 and projected to reach $89.72 billion by 2034, isn’t just growing—it’s evolving in ways that would have seemed impossible just a few years ago. Plastic, once the industry’s guilty secret, is undergoing a remarkable metamorphosis that deserves our attention and, dare I say, our appreciation.

For decades, we’ve had a complicated relationship with plastic in our beauty routines. We’ve loved how it protected our favorite serums, kept our creams fresh, and made our products affordable. But we’ve also felt that nagging guilt every time we tossed an empty bottle in the trash, knowing it might outlive us by centuries. The beauty industry produces approximately 120 billion units of packaging waste annually, and that staggering number has been weighing on our collective conscience. Now, finally, the industry is listening—and responding with innovation that’s as exciting as it is necessary.

1. Why We Can’t Just Break Up With Plastic (Yet)

Let’s be honest: if there were an easy alternative to plastic that worked just as well, we would have found it by now. The truth is more nuanced and, frankly, more interesting. Plastic has become indispensable to modern beauty for reasons that go beyond corporate convenience or cost-cutting.

Think about your favorite vitamin C serum, that expensive retinol treatment you save for special occasions, or the peptide-packed eye cream that actually seems to work. These sophisticated formulations are remarkably fragile—they can degrade when exposed to oxygen, light, or moisture. Plastic packaging, particularly modern designs with advanced barrier technologies, creates a protective fortress around these precious ingredients. It’s lightweight enough that you can toss products in your travel bag without worry, flexible enough to squeeze out every last drop, and resilient enough to survive the occasional bathroom counter tumble.

The United States alone generated over 7.9 billion units of cosmetic waste in 2018. These numbers stopped feeling like mere statistics and started feeling personal as we watched documentaries about ocean plastic and heard stories about marine life affected by our consumption. But here’s where the story takes an encouraging turn: the industry isn’t ignoring this crisis. Instead, it’s channeling creativity and resources into solving it in ways that feel genuinely hopeful.

2. The Rules Are Changing (And That’s a Good Thing)

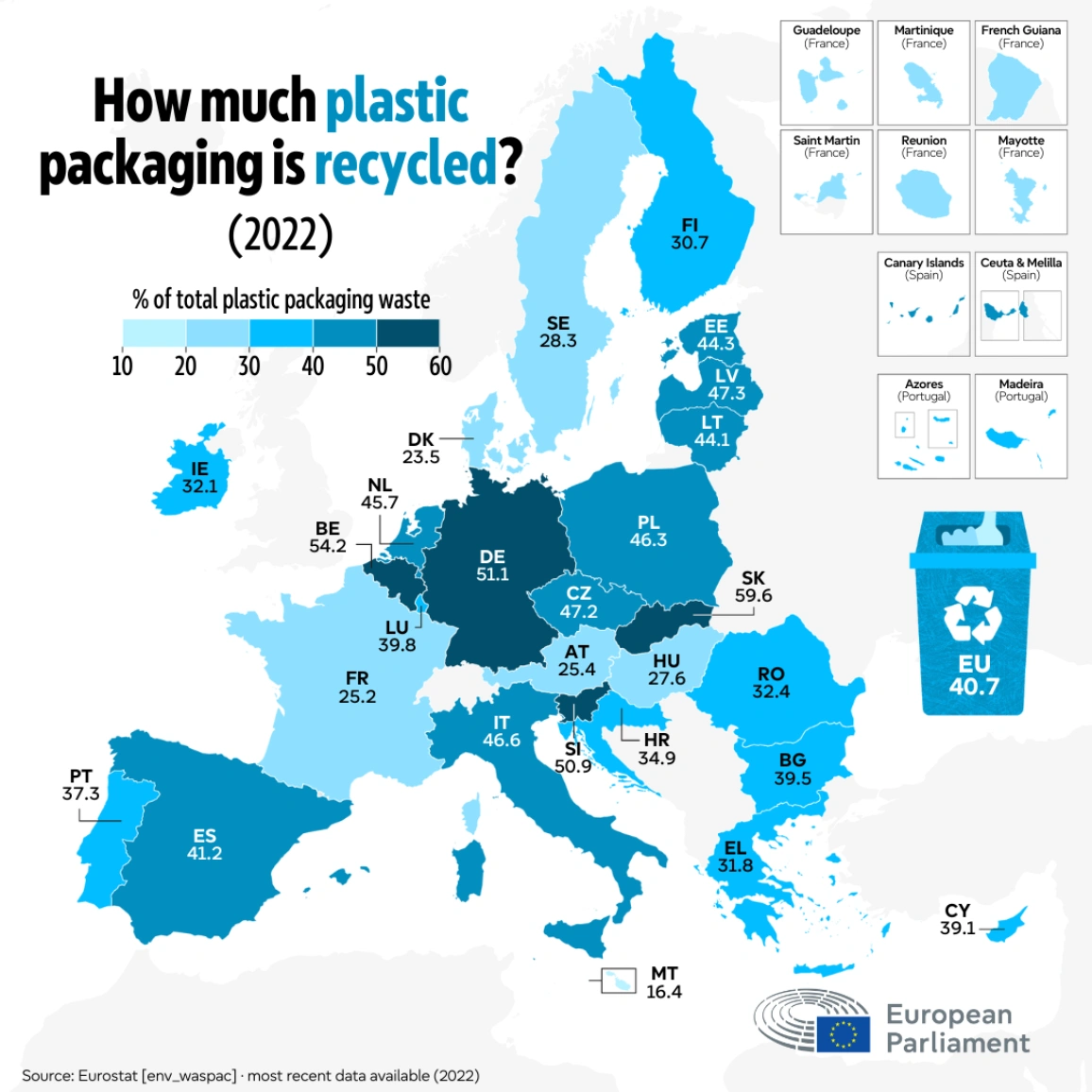

Sometimes we need a little push to do the right thing, and that’s exactly what’s happening with new regulations reshaping the packaging landscape. The European Union’s Packaging and Packaging Waste Regulation, which entered force in February 2025 with full application by August 2026, is setting standards that will ripple across the global industry. This isn’t bureaucratic red tape—it’s a blueprint for transformation.

These regulations demand that plastic packaging achieve at least 70% recyclability, a threshold that many current packaging formats simply can’t meet. Think of all those gorgeously metallic tubes and multi-layered containers that look so luxurious on your vanity. Recent assessments in Germany, Austria, and Switzerland revealed that many of these beautiful packages are failing recyclability targets because they combine incompatible materials that can’t be separated during recycling. It’s been a wake-up call.

California is leading the American charge with Senate Bill 54, mandating 100% recyclable packaging by 2032 with minimum 65% recycling rates. Other states are watching closely, likely to follow suit. Extended Producer Responsibility programs are expanding too, shifting the burden of end-of-life management from overwhelmed municipalities to the manufacturers who created the packaging in the first place.

What makes this exciting rather than merely punitive is how companies are responding. Instead of fighting the inevitable, many are embracing these constraints as catalysts for creativity. When you can’t rely on multi-layered materials or excessive metallization, you have to think differently about how to make packaging feel special, functional, and premium. And that’s where the real innovation is happening.

3. The Material Revolution: When Science Meets Conscience

Walk into a beauty store today, and you might not immediately notice the quiet revolution happening on those shelves. But pick up a tube, really look at it, feel it, and you’ll start to see how materials are changing in ways both practical and profound.

Simplicity as Sophistication

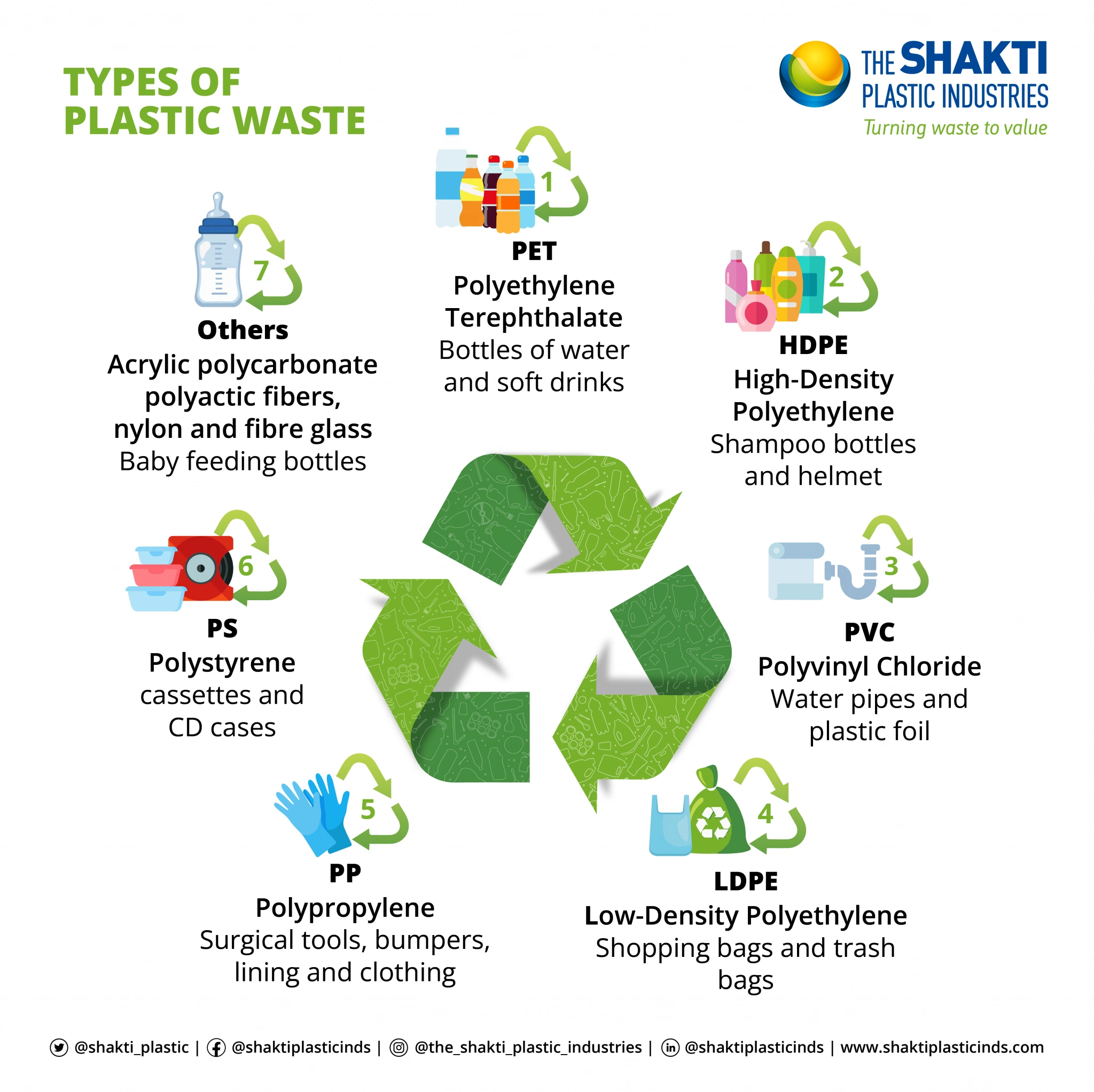

The mono-material movement might sound technical, but its philosophy is beautifully simple: what if we made packaging from just one type of plastic so it could actually be recycled? Traditional tubes often combined aluminum and plastic layers—impossible to separate, destined for landfills. The new generation uses a single polymer family, typically polyethylene, throughout the entire tube: the body, the head, even the cap.

This shift required genuine problem-solving. How do you maintain the barrier properties that keep your expensive retinol from oxidizing if you can’t use multiple materials? Enter Plastic Barrier Laminate tubes, which achieve protective performance while remaining fully recyclable. It’s the kind of innovation that happens when constraints force us to be clever rather than simply adding more layers.

The aesthetic challenge was real, though. Without metallized layers or multi-color laminations, how do you make packaging feel luxurious? Designers responded with embossing, debossing, and soft-touch finishes that create a velvety, skin-like feel. It turns out that sustainability constraints don’t have to mean compromise—sometimes they inspire us to create beauty through texture and form rather than superficial flash.

Giving Plastic a Second Life

The post-consumer recycled (PCR) plastic market is experiencing explosive growth, projected to surge from $2,040 million in 2026 to $6,743.3 million by 2036. These aren’t just numbers—they represent a fundamental shift in how we think about waste. That plastic water bottle you recycled last week? It might become your next shampoo bottle.

Major beauty brands have committed to incorporating 25-100% recycled content across their packaging portfolios within defined timelines. What makes this particularly moving is that it addresses multiple problems simultaneously: reducing demand for virgin petroleum-based plastics, diverting waste from landfills and oceans, and proving that circular economy principles can actually work in practice.

Some brands are even incorporating ocean-recovered plastics—literally salvaged from marine environments before they can fragment into microplastics—into cosmetic packaging. There’s something deeply satisfying about this: plastic that once threatened ocean life being transformed into containers for products that make us feel beautiful. It’s redemption in material form.

The quality of PCR plastics has improved dramatically too. Early concerns about color consistency, strange odors, and mechanical weaknesses have been largely resolved through better sorting and washing technologies. Modern PCR materials can even meet food-grade standards, ensuring they’re safe for cosmetic contact.

Nature’s Plastics: The Bio-Based Future

Bioplastics represent perhaps the most philosophically interesting development in this space. What if we could make plastic-like materials from renewable sources like plants rather than petroleum? Polyhydroxyalkanoates (PHAs), produced through bacterial fermentation of sugars, can be molded into jars and tubes that actually biodegrade in soil and marine environments. Imagine packaging that could return harmlessly to nature rather than persisting for centuries.

Polylactic acid (PLA), derived from fermented plant starches like corn or sugarcane, offers transparency comparable to traditional PET with the added benefit of compostability under industrial conditions. Bio-based polyethylene, chemically identical to conventional PE but derived from bioethanol, provides an interesting middle ground: it’s not biodegradable, but it doesn’t require fossil fuels and works perfectly with existing recycling systems.

The story gets more complex when you dig deeper, though. Not all bioplastics are automatically better for the environment—it depends on how the feedstock is grown, how much energy processing requires, and what actually happens at end of life. Bioplastics made from waste biomass or non-food crops grown sustainably? Genuinely promising. Those relying on intensively cultivated commodity crops competing with food production? More questionable. The nuance matters, and thankfully, more brands are doing the homework to ensure their bio-based choices make sense.

4. When Packaging Becomes a Beauty Tool

Here’s where things get really fun. Modern cosmetic packaging isn’t content to just hold product—it wants to enhance the entire experience in ways that feel almost magical.

The Touch of Metal, The Feel of Luxury

Have you noticed how many eye creams now come with metal applicator tips? These aren’t just design flourishes. That cooling sensation when you apply your under-eye treatment comes from the metal’s thermal conductivity, creating an instant de-puffing effect that actually works. It’s like having a tiny spa tool built right into your product.

Ceramic applicators offer a similar experience with a different vibe—smooth and cool like jade rollers, but permanently attached so you never lose them in your bathroom drawer. For people with sensitive skin, ceramic feels particularly gentle and non-reactive, delivering massage benefits without irritation.

The psychology behind this trend is fascinating. We’re not just applying products anymore; we’re performing rituals. The packaging contributes to that sense of ceremony, transforming routine skincare into a moment of self-care. When your tube includes a built-in massage tool, it elevates the perceived value far beyond the formulation alone.

The Pleasure of Touch

Luxury whispers now rather than shouts. The latest premium packaging speaks through haptics—how it feels in your hand. Brands are moving away from loud gold foiling and busy graphics toward matte finishes and soft-touch varnishes that create a velvety sensation against your fingertips.

These soft-touch coatings aren’t just pleasant; they’re functional too, providing anti-slip grip. But more importantly, they communicate quality through a sense that photographs can’t capture. It’s the tactile equivalent of that perfect weight a high-end product has when you hold it.

Embossed logos and design elements take this further, creating physical depth that shifts with light and catches your fingers. There’s something permanent and intentional about a logo that’s been pressed into packaging rather than just printed on top. It suggests craftsmanship, attention to detail, care. Some brands are even incorporating Braille elements, adding inclusive functionality while enhancing the overall tactile richness.

This emphasis on touch responds to something we’ve lost in our increasingly digital shopping experiences. When we can’t smell and test products in stores, packaging that delivers satisfying sensory experiences upon unboxing helps compensate for that missing dimension. It’s why unboxing videos have become their own genre—the packaging experience itself has become content worth sharing.

Small But Mighty

Something lovely is happening with product sizes. Those tiny tubes that used to feel like disappointing samples? They’re being reimagined as sophisticated, full-size products in their own right. Small-diameter tubes (16mm/19mm) that once held throwaway samples are now being paired with expensive applicator tips and premium formulations to create 10-15ml “concentrated luxury” treatments.

This shift reflects changing attitudes about consumption. Rather than assuming bigger is always better, we’re recognizing that a 10ml eye cream actually represents months of use when applied as directed. Small formats reduce waste from products expiring before we finish them, and they fit into the tiny handbags fashion has been favoring.

There’s something psychologically satisfying about products scaled to actual needs. It feels edited, intentional, refined—like you’ve curated your routine rather than accumulated stuff. And when travel reemerged after pandemic restrictions, these perfectly portable sizes suddenly felt essential rather than insufficient.

5. Closing the Loop: The Circular Dream

The ultimate goal isn’t just better plastic—it’s systems where materials never become waste at all. This is harder than it sounds, but the progress happening right now is genuinely encouraging.

The Recycling Reality Check

Let’s talk honestly about recycling for a moment. Those recycling symbols on packaging? They don’t guarantee your container will actually be recycled. Official EU statistics show that while approximately 35% of plastic packaging waste was directed toward recycling in 2014, only 5% actually ended up in new domestic packaging. That dramatic gap reveals how far we still need to go.

Nearly 70% of plastic waste generated in the cosmetics market isn’t recyclable through existing systems. Size matters here—many mascara tubes and lip gloss containers are simply too small for automated sorting equipment, falling through screens or being diverted to trash even when you’ve dutifully placed them in the recycling bin. Residual product creates contamination issues too. That sticky foundation or oily cream left in containers can compromise entire batches of recovered plastic.

But here’s the thing: awareness of these problems is driving solutions. Knowing that pretty metallized tubes can’t be recycled is prompting brands to redesign them. Understanding that small containers need special handling is spurring dedicated cosmetic packaging collection programs. The gap between aspiration and reality is narrowing.

Refill Revolution

Some of the most inspiring innovation is happening in refillable packaging systems. Between 2017 and 2023, refill offerings increased by up to 279% in major markets including Germany, the UK, the U.S., and France. These aren’t just token gestures—brands like Beauty Kitchen have saved over 4 million single-use plastic bottles from landfills through their circular packaging programs.

Refill systems work through a simple but powerful logic: invest in a durable, beautiful primary container designed for years of use, then replenish it with replacement cartridges or pouches that use a fraction of the packaging. When done right, the initial container feels like something worth keeping—substantial glass, smooth metal, or thick-walled plastic with a pleasing weight and finish. The refills are designed for minimal packaging, often collapsible pouches that use 70-90% less material than the original.

The consumer experience makes or breaks these systems. Beauty Kitchen’s program achieves over 60% customer participation—far higher than typical voluntary return rates—through thoughtful design including prepaid return packaging and clear communications about the environmental impact. When refilling feels seamless rather than burdensome, when it feels elevated rather than cheap, people embrace it.

Australian brand INIKA Organic took a comprehensive approach, incorporating 90% sustainable and reused materials including sugarcane-derived bioplastics and post-consumer recycled plastics. This reduced their virgin plastic use by 84%, from 8.1 tonnes to just 1.3 tonnes. They partnered with CleanHub to support plastic waste collection in regions lacking formal recycling infrastructure, recognizing that packaging design alone can’t solve systemic waste challenges.

These examples prove that dramatic change is possible. They’re not happening at companies with unlimited resources or tiny production volumes—they’re being implemented by real brands selling to real customers who appreciate the effort and want to be part of the solution.

6. What This Means for You and Me

All this innovation is wonderful, but it only matters if we participate. The good news is that participation is getting easier and more rewarding than ever.

Voting With Our Wallets

Consumer attitudes are shifting faster than many people realize. Younger generations particularly—Millennials and Gen Z—increasingly consider packaging sustainability when making purchase decisions. We’re willing to pay modest premiums for brands that align with our values, and we’re definitely willing to switch brands when better options emerge.

But we’re also getting smarter about greenwashing. Vague claims about being “eco-friendly” or “natural” don’t cut it anymore. We want specifics: What percentage is recycled content? Can this actually be recycled in my area? What happens to the packaging at end of life? Brands that communicate transparently, acknowledging both achievements and ongoing challenges, earn more trust than those claiming perfection.

Social media has amplified our collective voice. When someone shares an impressive unboxing experience with sustainable packaging that’s also beautiful, that content reaches thousands or millions of people. Packaging that combines environmental responsibility with distinctive aesthetics generates organic sharing that extends brand awareness far beyond traditional advertising. We’ve become influencers in our own right, using our platforms to celebrate brands doing things right.

Regional Flavors

It’s fascinating how sustainability priorities vary across different parts of the world, reflecting cultural values and local realities. European consumers, particularly in Germany and Nordic countries, prioritize packaging minimization and recyclability with an intensity that’s culturally embedded. Strong environmental movements and developed recycling infrastructure make sustainable choices feel expected rather than exceptional.

North American markets are more fragmented. Coastal urban areas demonstrate European-level environmental consciousness, while interior and rural markets often prioritize convenience and value. This creates challenges for brands seeking uniform packaging strategies across diverse markets.

Asian markets are evolving rapidly. Japanese consumers value minimalist aesthetics and quality that naturally align with sustainable design, while South Korean beauty markets emphasize innovation and trends—with sustainability gaining particular traction among younger consumers influenced by global environmental discourse.

Emerging markets face different challenges where affordability and accessibility often supersede environmental considerations for mainstream consumers. Limited recycling infrastructure means recyclable packaging may still reach landfills. Yet these markets also offer leapfrog opportunities, establishing circular practices from the beginning rather than retrofitting established systems.

The E-Commerce Effect

Online shopping has transformed packaging requirements in ways both challenging and promising. Products must withstand shipping stresses far exceeding retail distribution—repeated drops, compression, temperature fluctuations. This has driven adoption of protective plastics that can increase overall material use.

But e-commerce also enables innovations impossible in traditional retail. Direct-to-consumer brands can implement refill systems where durable containers ship initially followed by refill pouches. They can incorporate detailed recycling instructions and mail-back return programs. The ongoing customer relationship inherent to subscription models supports circular packaging systems difficult in transactional retail.

The unboxing experience has become a critical brand touchpoint where packaging replaces in-store browsing and staff interaction. Sustainable materials must deliver Instagram-worthy moments without compromising environmental credentials—a challenging balance driving innovation in premium-feeling recycled papers and elegant minimalist designs.

7. Looking Ahead With Hope

The story of plastic in cosmetic packaging is still being written, and the chapters ahead feel increasingly optimistic. We’re witnessing material science advances that once seemed like science fiction: plastics made from bacteria-fermented sugars that biodegrade harmlessly, recycling technologies that can break plastics down to molecular building blocks and rebuild them into virgin-quality materials, and coating technologies that provide barrier protection without multi-material complications.

But perhaps more encouraging than any specific technology is the fundamental shift in mindset happening across the industry. Sustainability isn’t a marketing department afterthought anymore—it’s a core business objective with board-level oversight. Regulations are providing clear targets and accountability. Consumers are demanding and rewarding sustainable choices. The alignment of these forces creates momentum that feels genuinely transformative.

Infrastructure gaps remain real obstacles. Even brilliantly designed recyclable packaging fails without collection and processing systems to handle it. But Extended Producer Responsibility policies are creating funding mechanisms and incentives for infrastructure development. Specialized collection programs for cosmetic packaging are emerging. Technology advances in sorting and processing are expanding what systems can effectively handle.

Consumer education efforts are becoming more sophisticated too. Clear, standardized labeling like “How2Recycle” instructions are being adopted by leading brands, reducing confusion about proper disposal. In-store communication and take-back programs are appearing in specialty beauty retailers. Social marketing campaigns are making sustainable behavior feel normal and aspirational rather than difficult and obligatory.

8. The Beauty of Transformation

There’s something deeply satisfying about watching an industry transform in response to real problems. Plastic packaging in cosmetics isn’t becoming irrelevant—it’s becoming better. It’s learning to balance the functional requirements we genuinely need with the environmental responsibility we genuinely owe.

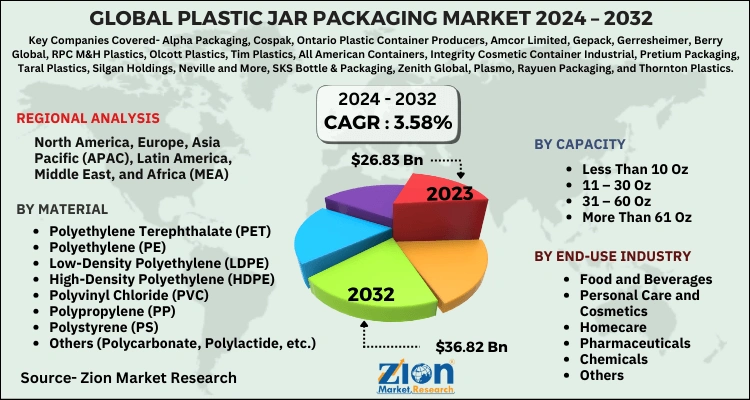

The plastic cosmetic packaging market continues growing, reaching toward $36.78 billion by 2033. But this growth doesn’t represent thoughtless consumption amplified—it represents innovation accelerated. Every new package design incorporating mono-materials or recycled content, every refill system that saves bottles from landfills, every bioplastic that proves materials can come from plants instead of petroleum—these are victories worth celebrating.

We’re collectively learning that sustainability doesn’t require sacrifice. It requires creativity, commitment, and collaboration. The most exciting packaging innovations happening right now don’t ask us to choose between performance and responsibility, between beauty and conscience. They deliver both, proving that doing the right thing can also feel wonderful.

So the next time you reach for a cosmetic product, take a moment to really look at its packaging. Notice if it’s made from recycled materials or designed for recyclability. Feel the texture—that soft-touch finish might represent someone’s creative solution to making mono-material packaging feel luxurious. Check if refills are available. Read the recycling instructions.

Every purchase is a small vote for the kind of world we want to live in. And increasingly, the beauty industry is offering us choices worth voting for. The transformation is happening. We’re part of it. And honestly? That feels pretty beautiful.

FAQs

Is plastic packaging in cosmetics actually becoming more sustainable, or is it just greenwashing?

Yes, real change is happening. Major brands are now using 25-100% recycled content in their packaging, and new regulations like the EU’s requirement for 70% recyclability by 2026 are forcing companies to follow through. However, greenwashing still exists. Look for specific numbers and third-party certifications rather than vague claims like “eco-friendly.” Trust brands that openly discuss both what they’ve achieved and what they’re still working on, rather than those claiming to be perfect.

What are mono-material packages, and why do they matter?

Mono-material packages are made from just one type of plastic (usually polyethylene) instead of mixing different materials together. Traditional tubes combined aluminum and plastic layers that couldn’t be separated, so they ended up in landfills. The new single-material tubes can actually be recycled. This matters because nearly 70% of cosmetic plastic waste can’t be recycled due to mixed materials. Mono-material design fixes this problem, turning packages that just looked recyclable into ones that truly are.

What happens to cosmetic packaging when I put it in my recycling bin?

Unfortunately, much of it doesn’t get recycled. In the EU, while 35% of plastic packaging goes to recycling facilities, only 5% becomes new packaging. Many cosmetic containers are too small for sorting machines and fall through the cracks. Leftover product, metallic finishes, and certain dark colors also cause problems. This doesn’t mean you should stop trying—it means we need better systems. Check if your favorite brands offer mail-back programs or store drop-off options, which often work better than curbside recycling for cosmetics.

Are bioplastics better for the environment than regular plastics?

Not always—it depends on how they’re made. Bioplastics from waste materials or crops grown sustainably can be genuinely better. But those made from intensively farmed crops can have issues with land use, water consumption, and competing with food production. Sometimes bio-based polyethylene (which recycles easily but doesn’t biodegrade) is smarter than biodegradable plastics that can contaminate regular recycling. The takeaway: bioplastic doesn’t automatically mean better—the details matter.

What advanced technologies are improving plastic packaging barrier properties without using multiple materials?

New technologies protect your products without making packaging un-recyclable. Five-layer tubes with an EVOH barrier layer keep oxygen out (protecting ingredients like retinol and vitamin C) while staying recyclable. Airless pumps use vacuum systems to prevent air from reaching the product. Ultra-thin coatings applied to plastic surfaces provide protection without affecting recycling. Some packages even have built-in oxygen absorbers that actively remove any oxygen that gets through. These innovations mean you don’t have to choose between product freshness and recyclability anymore.

How can I properly dispose of cosmetic packaging to maximize its chance of being recycled?

Start by checking if your local recycling accepts cosmetic packaging—many don’t. Rinse out containers to remove leftover product since residue can contaminate recycling. Separate different parts: pop off caps, remove pumps, peel labels. Look for brand take-back programs or collection bins at stores like Sephora—these often work better than home recycling. TerraCycle offers mail-back options for hard-to-recycle items. Check for “How2Recycle” labels on packaging for specific instructions. If recycling isn’t an option, see if refills are available. And remember: buying less, choosing refillable products, and supporting sustainable brands matters more than perfect disposal of disposable packaging.