Luxury beauty used to be measured in grams. A fragrance bottle with a thick glass base, a lipstick built like a metal bullet, or a jar that landed on a vanity with a satisfying “thud” all transmitted the same message: this is expensive, this is serious, this is worth it. Weight equaled worth; mass equaled prestige.

By 2026, that old equation is breaking down. As carbon footprints become consumer-facing metrics, regulations tighten around packaging waste and Scope 3 emissions, and e commerce logistics magnify the cost of moving heavy objects, “heavy” is no longer automatically synonymous with “luxurious.” The aesthetic and technical frontier of luxury packaging has shifted. The new premium is light, precise, refillable, and smart.

This is the era of “Lightweight Luxury”: a design language and engineering approach that keeps emotional richness and sensorial pleasure but strips away unnecessary material. It replaces the old brute-force paradigm—more glass, more metal—with a new one built on intelligence: smart lightweighting, tactile design, and refill systems that separate permanent “heirlooms” from minimal “husks.” In 2026, this is not a fringe experiment. It is rapidly becoming the most modern expression of prestige in cosmetic packaging.

1. From Thud to Thoughtful: Why Luxury Is Getting Lighter

For decades, the luxury beauty industry relied on a simple sensory logic. Heavier packaging suggested a higher concentration of active ingredients, more craftsmanship, and more value. A weighty glass flacon implied that the brand had spared no expense; a thick acrylic jar base made a small volume of cream feel more substantial. Consumers might not articulate this consciously, but they felt it in the hand and heard it in the sound of glass or metal hitting a surface.

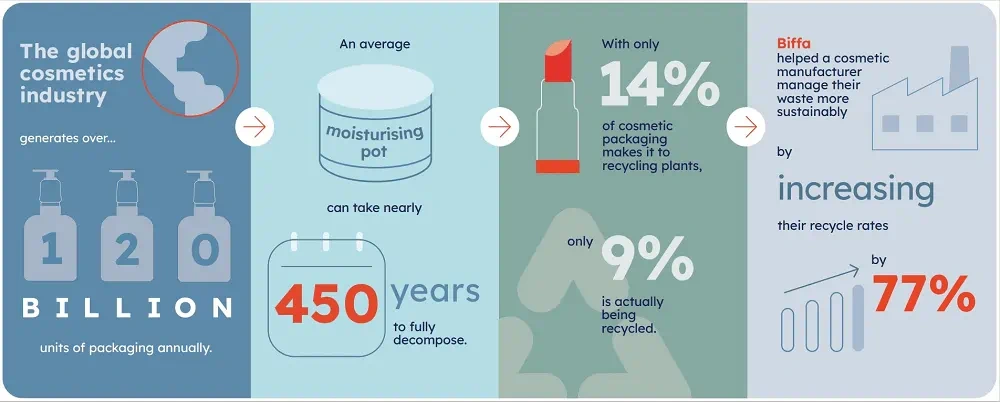

This logic flourished in a world where the environmental impact of packaging was largely invisible. The carbon cost of thick glass walls, the fuel used to ship heavy containers, and the difficulty of recycling multi-material components were seldom part of the conversation. Luxury could indulge in excess without needing to justify it beyond aesthetics.

By 2026, the context has changed. Sustainability has moved from a marketing afterthought to a central pillar of brand strategy. Carbon disclosure frameworks and extended producer responsibility schemes draw a direct line between packaging decisions and measurable environmental impacts. Consumers, especially younger demographics, have internalized the idea that materials, transport, and waste are part of a product’s true price.

At the same time, e commerce and direct-to-consumer channels have exploded. Products now travel through complex distribution networks, facing more touchpoints, more handling, and more cost per gram. Shipping “heavy air”—oversized packages that contain small volumes of formula—is not just environmentally problematic; it is financially inefficient in a world of rising logistics costs.

Against this backdrop, the old equation—weight equals luxury—begins to look out of date. The new question is: can luxury be expressed through design intelligence instead of material excess? Can a package feel just as special while being lighter, more efficient, and more compatible with a circular economy? The answer emerging in 2026 is yes, and the industry is exploring three main levers to make it happen: smart lightweighting, haptics over heaviness, and the “heirloom and husk” refill model.

2. Smart Lightweighting: Engineering Light Without Losing Presence

At first glance, “lightweighting” may sound like a simple directive to use less material. In practice, authentic smart lightweighting is a sophisticated engineering exercise. The goal is to reduce mass and environmental impact while preserving—or even enhancing—structural integrity, shelf presence, and perceived value.

Rather than trimming material indiscriminately, smart lightweighting starts by analyzing where material actually contributes to performance and where it merely inflates weight. Through modeling, simulation, and advanced forming processes, packaging engineers identify stress points, optimize wall thickness, and redesign internal geometries so that every gram has a job.

Invisible Reduction in Glass

Glass remains a cornerstone of luxury cosmetic packaging, especially in fragrance and skincare. However, it is also one of the heaviest common materials. In 2026, leading glassmakers and premium brands are targeting weight reductions in the range of 30% to 50% while maintaining the same external footprint and fill volume. To the consumer, the bottle still looks substantial. Behind the scenes, it is significantly more efficient.

Uniform, ultra-thin walls play a central role. Traditional molds often produce uneven thickness—extra material pooled in certain areas to create a margin of safety. Newer forming techniques, combined with better mold design and process control, allow glass to be distributed evenly. This uniformity means engineers can lower overall thickness without sacrificing strength.

Another major target is the classic “false bottom,” the heavy slab of glass that sits beneath the liquid in many perfume and skincare bottles. Historically, it added a visual illusion of depth and weight. Smart lightweighting challenges this convention. By thinning or eliminating the false bottom and using alternative optical tricks—such as internal shaping, framing, or light-guiding cuts—designers can maintain visual drama with far less material.

The result is a bottle that looks just as generous and sculptural on a shelf but weighs noticeably less in the hand. Shipping becomes more efficient; less raw material is needed per unit; and life-cycle assessments improve, all without asking consumers to accept a visibly smaller or less impressive object.

The “Skin” Effect: Packaging as Tensioned Membrane

Beyond invisible optimization, smart lightweighting is also reshaping the visible language of luxury. One emerging aesthetic is the “skin effect”: packaging that appears as thin and tensioned as a water droplet clinging to a surface.

In this approach, rigid materials—glass, engineered polymers, thin metals—are pushed close to their structural limits. Walls curve gently, edges taper, and surfaces appear stretched, as though the container is just barely holding the liquid inside. Rather than disguising thinness, these designs celebrate it.

This aesthetic offers several advantages. It visually communicates efficiency and modernity, aligning with 2026 sustainability narratives. It invites interesting interactions with light, as thin walls transmit and refract in more delicate ways than thick blocks. And it differentiates clearly from older, heavy forms, signaling that the brand is in step with current design and environmental thinking.

Achieving the skin effect requires precision. Ultra-thin structures are more vulnerable to impacts and thermal stress. Engineers may incorporate subtle ribs, internal skeletons, or strategic curves that distribute force while keeping visible surfaces seeming weightless. The goal is to deliver a new kind of strength—one that is rooted in geometry and tension rather than brute mass.

Beyond Glass: Polymers, Mono-Materials, and Metals

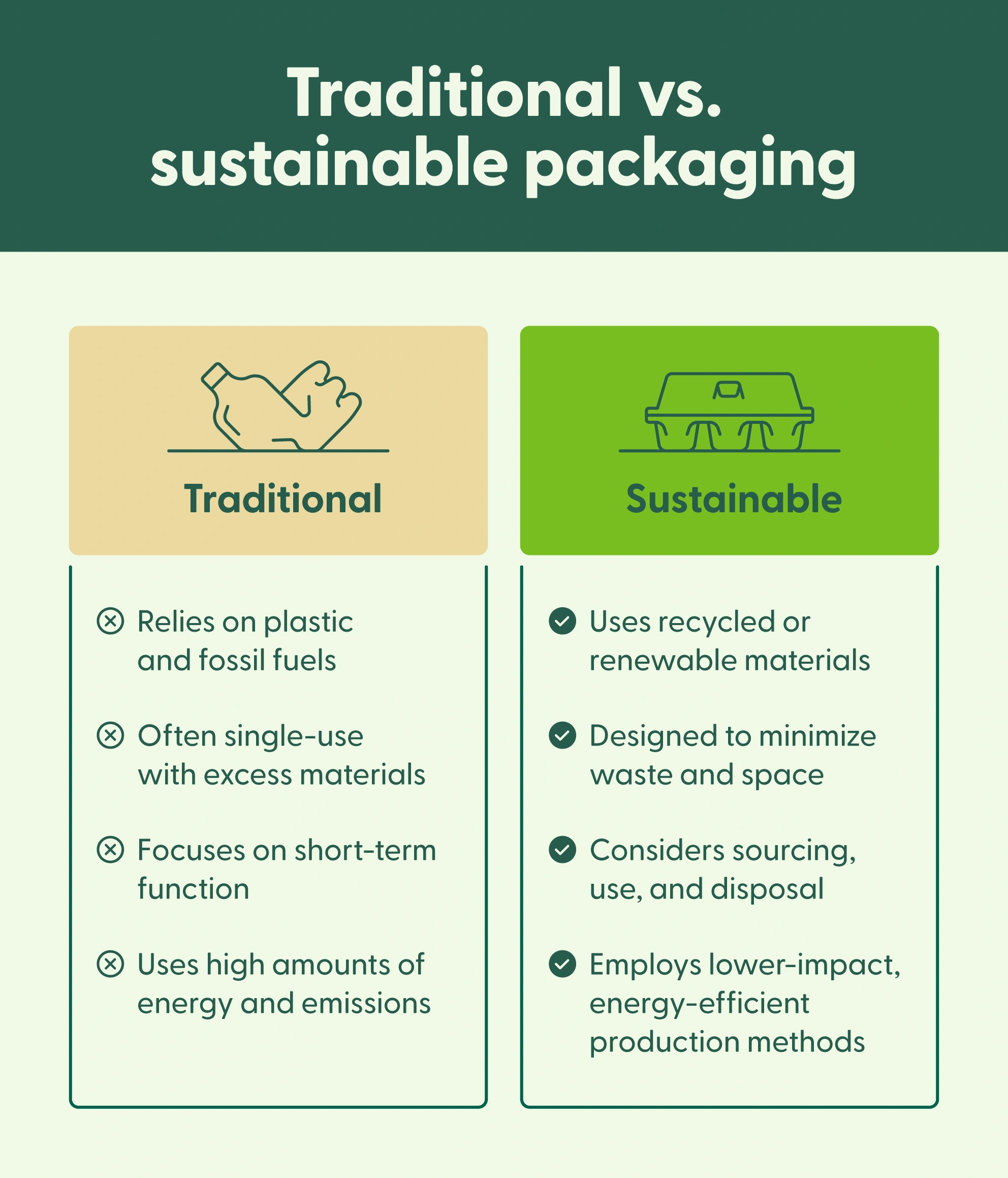

Smart lightweighting extends across all materials. In polymers, the focus is shifting toward thin-walled constructions that use high-performance resins but avoid complicated multi-layer laminates that hinder recyclability. Mono-material approaches—where a bottle, cap, and pump are designed to be mostly one resin type or at least easily separable—support the circularity goals that are gaining prominence by 2026.

Thin-walled polymer components gain stiffness and durability through clever geometries: internal ribs, hexagonal or ribbed cross-sections, and other micro-architectures that resist deformation without visibly adding bulk. Design and engineering work hand in hand to produce forms that feel sleek and purposeful, not flimsy.

Metals, particularly aluminum, play a growing role in smart lightweighting. Aluminum combines low density with strength and excellent recyclability. It can be formed into thin shells that are robust enough for daily use, and its thermal conductivity gives a cool touch that consumers instinctively associate with quality. Modern finishing techniques—anodizing, brushing, micro-embossing—allow aluminum surfaces to look as refined as glass or more traditional luxury metals. As brands look to reduce glass and plastic weight without losing premium cues, aluminum is increasingly attractive.

In all of these cases, the philosophy is the same: remove unnecessary mass, optimize the structure, and use material science and engineering to do more with less.

3. Haptics Over Heaviness: Rebuilding the Luxury Feel

The moment a consumer picks up a product, the illusion can either hold or collapse. For decades, heft did much of the work. If that heft is gone or substantially reduced, something else must take its place. The industry’s answer in 2026 is haptics: a deliberate focus on touch, texture, micro-detail, and temperature to create a new sensory language of luxury.

Rather than leaning on weight as a crude proxy for value, brands are using surfaces and tactile feedback to convey sophistication, care, and investment. The hand is still engaged, but in more nuanced and interesting ways.

Tactile Distraction and Sensory Complexity

“Super-tactile” finishes are central to this strategy. A thin-walled bottle or compact that would otherwise feel anonymous can become memorable when the fingers discover a velvety matte surface, a stone-like grain, or fine micro-embossed patterns.

This approach works on multiple psychological levels. Texture complexity suggests bespoke tooling and craftsmanship. The brain tends to associate intricate sensory stimuli with effort and quality. Haptic surprise—when an object feels unexpectedly soft, rough, cool, or grippy—creates small moments of delight that anchor the product in memory, much as the old “thud factor” did.

Importantly, tactile richness does not merely distract from lightness; it reframes it. The narrative shifts from “this feels too light” to “this feels thoughtfully made.” Over time, consumers learn to associate these new, more nuanced cues with premium positioning.

Matte and Frosted: Soft-Focus Glamour

Matte and frosted finishes are particularly well suited to lightweight luxury. On thin glass, sandblasting or acid etching can transform a potentially fragile-feeling surface into something that reads as soft, controlled, and elevated. The eye perceives a gentle diffusion of light; the hand experiences a smooth, almost velvet touch.

These finishes align with broader 2026 trends in beauty and fashion: “quiet luxury,” understated refinement, and calming, sanctuary-like aesthetics for home and personal care. A frosted lightweight bottle on a bathroom shelf can look as expensive as a thick, glossy one—arguably more so—because it feels contemporary and deliberate rather than ostentatious.

Designers can combine frosting with clear windows or channels that expose the product inside, balancing sensuality and transparency. Frosted gradients, bands, or patterns add further visual interest without adding any physical weight.

Stone, Ceramic, and Nature-Inspired Textures

Another way to build perceived value into lighter packages is to make them feel like materials historically associated with permanence and craft, such as stone or ceramic. Bio-composites, aluminum, or coated plastics can be given textures that evoke unpolished slate, volcanic rock, or unglazed pottery.

This strategy taps into powerful associations. Stone implies durability and connection to the earth. Ceramic suggests artisanal work and care. When a compact shell, cap, or outer case feels like a fragment of sculpture, it carries a narrative of intentionality—even if the underlying structure is thin and optimized.

The trick is to achieve authenticity in sensation. The temperature, micro-roughness, and even the way light plays across the surface need to harmonize so that the overall impression is coherent. When done well, the user experiences a hybrid: all the advantages of modern, lightweight engineering wrapped in a sensorial story of craft and nature.

Micro-Embossing and Micro-Relief

Micro-embossed and micro-engraved surfaces provide another layer of tactile interest. Fine patterns can be created in metals, plastics, or even paper-based labels, forming subtle ridges and recesses. These micro-geometries catch light in intriguing ways and give the fingers delicate textures to explore.

Beyond aesthetics, micro-relief can serve functional purposes. Enhanced grip is particularly valuable for lighter, smoother forms that might otherwise feel slippery. Patterns can also be brand-coded—featuring monograms, signature motifs, or distinctive graphic language—turning every touch into an encounter with brand identity.

Because micro-embossing requires precise tooling and manufacturing control, it implicitly signals investment. Consumers may not know how the effect is achieved, but they sense that it is not trivial, and this sense feeds back into their perception of quality.

4. The Refill Revolution: The Heirloom and the Husk

If smart lightweighting and haptic design reimagine the object, refill systems reimagine its lifespan. In the 2026 landscape, refillable packaging is not just a sustainability feature; it is a central pillar of luxury strategy. The most compelling expression of this is the “heirloom and husk” model: a deliberate separation between a permanent, luxurious outer casing and a minimal, efficient inner refill.

Heirloom: Where Luxury and Weight Belong

The heirloom is the shell that stays. It is deliberately substantial, visually striking, and often crafted from heavier, more durable materials—zamak, polished brass, robust glass, or carefully finished aluminum. Its role is no longer just to contain the product but to function as an object of desire in its own right.

An heirloom perfume bottle might be a sculptural glass or metal form that sits like a piece of art on a dressing table. A skincare jar could feature a weighty metal lid with engraved initials. A lipstick case might be a richly detailed outer cladding that clips around a slim refillable bullet.

Because the heirloom is designed to endure, the environmental logic shifts. Instead of discarding a heavy vessel after one cycle, the user keeps it for many. The weight that once represented waste is transformed into a long-term asset. Emotional value and environmental responsibility reinforce each other rather than being in tension.

Customization deepens this bond. Engraving, color choices, limited editions, and modular decorative elements make the heirloom feel personally significant. Consumers are more likely to keep and care for objects that carry their identity or tell a story, extending the life of the packaging and strengthening brand loyalty.

Husk: Smart Lightweighting in Its Purest Form

Nested inside the heirloom is the husk. This is the component that actually contains the product and is meant to be replaced: a thin-walled cartridge, vial, or pod that embodies smart lightweighting at its most pragmatic.

The husk is typically designed with minimal material, often relying on mono-material constructions to facilitate recycling. Visual presence is stripped back; the husk does not need to be beautiful on its own because it is hidden during use. Its design priorities are structural sufficiency, compatibility with the heirloom interface, and environmental performance.

This division of roles allows brands to concentrate luxury codes in the heirloom while making the husk as efficient as possible. Over multiple refills, the cumulative reduction in material and carbon footprint compared to single-use heavy packs can be substantial.

Psychological and Business Implications

The heirloom-and-husk model elegantly resolves the emerging tension between desire and duty. The user experiences the familiar pleasures of luxury packaging—the weight, the shine, the tactile richness—through the heirloom. Yet they can feel comfortable about the environmental impact because the discardable part is slim, optimized, and often clearly designed for recycling.

From a business standpoint, the model opens new possibilities. Heirlooms can be positioned as investment pieces, sometimes priced accordingly, while refills provide a more accessible ongoing revenue stream. Subscription programs become more feasible as shipping lightweight refills is cheaper and easier. The brand relationship deepens, as ownership of an heirloom shell implies a long-term commitment.

In 2026, this model aligns with broader trends toward circularity, regulatory pressure for reusable systems, and consumer fatigue with unnecessary waste. It is a particularly powerful expression of lightweight luxury because it shifts the conversation from individual product cycles to ongoing rituals and relationships.

5. Future Forms: Floating Bottles and Aluminum Ascendancy

As these principles embed themselves in the luxury beauty vocabulary, new visual archetypes start to crystallize. Two of the most emblematic for 2026 are the “floating” bottle and the rise of aluminum as a truly premium material.

Floating Bottles: Sculpted Negative Space

Floating bottles exploit negative space and optical illusions to dramatize material reduction. Imagine a fragrance flacon where the liquid appears to hover inside a frame-like structure, with glass walls so thin—or so cleverly delineated—that they nearly disappear. The base may be hollow or cut away, the shoulders supported by delicate arches, and the interior reservoir suspended within a larger void.

These designs send a clear message: there is no hidden bulk here. What you see is essentially what you get—liquid, air, and refined geometry. The effect is theatrical but honest. It turns lightweighting itself into a spectacle, transforming absence into a visual feature.

Floating bottles are particularly well aligned with the Instagram and TikTok era. Their play of light, reflection, and emptiness photographs beautifully and invites slow, close-up appreciation. As consumers share images and videos of these theatrical forms, the visual language of lightweight luxury spreads and normalizes.

Aluminum’s New Prestige

In 2026, aluminum continues its rise from functional workhorse to accepted luxury material. Several factors converge to enable this shift. Its low weight supports smart lightweighting goals; its recyclability resonates with sustainability narratives; and its thermal properties create a satisfying sense of cool solidity when touched.

Through precise forming, aluminum can be molded into sleek shells, minimal cylinders, and crisp-edged forms that feel contemporary and high-tech. Surface treatments expand its expressive range: brushed finishes signal modern sophistication; anodized colors invite playful or brand-specific palettes; micro-embossing adds haptic and visual texture; and selective polishing creates intriguing contrasts.

Aluminum works particularly well in heirloom shells, where durability and tactile quality are paramount. A pedigreed aluminum case around a lightweight plastic or glass husk offers both structural protection and sensory pleasure. Over time, as consumers grow familiar with aluminum in their favorite high-end products, the material’s status shifts. It becomes one of the default mediums of lightweight luxury, alongside thin glass and advanced polymers.

6. Storytelling and Consumer Education in a 2026 Context

Technically sophisticated packaging strategies only succeed if consumers understand and appreciate them. In 2026, storytelling and education are essential components of lightweight luxury.

Framing Lightness as Progress

The first narrative challenge is to ensure that lightness is not misread as cost-cutting. Brands must frame lighter packages as evidence of progress, not austerity. That means emphasizing the engineering and design achievements behind thin walls, complex textures, and elegant refill systems.

Stories can highlight how much material has been saved per unit, how transport emissions are reduced, or how refillable formats prevent waste over time. But they should also speak to artistry—how surface finishes are developed, how new silhouettes are sculpted, and how heirloom shells are crafted. The message is that luxury has become more thoughtful and future-aware.

Making Hidden Benefits Visible

Because many of the benefits of lightweight luxury are invisible—internal structure optimization, material choices, lifecycle improvements—visual aids help. Cross-section diagrams printed inside packaging, digital animations accessible via QR codes, or simple before-and-after illustrations can reveal what has changed beneath the surface.

Metrics can be translated into consumer-friendly terms. Instead of abstract percentages, brands might talk about “X fewer bottles’ worth of glass per year” or “Y fewer truckloads of packaging.” The aim is to make the scale of improvement tangible without overwhelming with technical detail.

Clarifying Refill Rituals

Refillable systems require some user education. Clear, intuitive instructions and reassuring demonstrations can turn potential friction into a satisfying ritual. On-pack icons that indicate “keep” vs. “replace,” simple diagrams showing how to swap husks, and brief videos on brand websites or social channels all contribute.

Emotionally, brands can position the refill ritual as an act of care—for oneself, for the object, and for the planet. Pouring or inserting a refill into a cherished heirloom shell can be framed as part of a personal routine, not a chore. As these behaviors become normalized, the perceived barrier to adopting refill systems drops.

Source: https://www.biffa.co.uk/biffa-insights/what-iff-cosmetic-waste-got-a-makeover

7. hallenges and Trade-Offs on the Road to Lightweight Luxury

While the direction is clear, the transition to lightweight luxury is not without challenges. Brands navigating this shift must balance performance, usability, authenticity, and cultural expectations.

Performance and Durability

Ultra-thin walls and lighter constructions must still protect products throughout their lifecycle. Shipping conditions can be harsh, and consumers expect premium products to arrive and remain pristine. Design teams need to invest in rigorous testing, exploring worst-case scenarios to ensure that weight reductions do not lead to unacceptable breakage or leakage rates.

Similarly, barrier performance must not be compromised. Some formulas are sensitive to oxygen, light, or moisture. Thinner walls may require new materials, coatings, or secondary packaging solutions to maintain product integrity. These decisions can introduce cost and complexity that must be weighed against environmental gains.

Usability and Accessibility

Lighter, slimmer packages and new refill mechanisms can pose challenges for certain users. People with limited dexterity, visual impairments, or reduced strength may struggle with tiny components or complex motions. Inclusive design principles—larger grip areas, clear tactile cues, audible clicks when components lock—are crucial.

Balancing elegance with ergonomics is a core design task. Texture plays a role: micro-embossing or rubberized inserts can add grip without compromising aesthetics. Designers must test with diverse users, not just idealized “average” consumers.

Authentic Sustainability vs. Greenwashing

As lightweighting and refill systems become part of the sustainability vocabulary, there is a risk that some brands may overstate their impact or implement only superficial changes. Token weight reductions or partially refillable systems that still send large volumes of material to landfill can attract criticism, especially under tightened regulatory and NGO scrutiny.

To maintain credibility, brands need to take a holistic view: considering material sourcing, energy use, transport, actual recycling rates, and the long-term behavior of consumers (for example, whether heirloom shells are truly reused). Communicating both achievements and limitations honestly builds trust in a crowded landscape of “green” claims.

Cultural and Regional Differences

Global beauty brands operate across markets with different cultural expectations. In some regions, heavy packaging may remain strongly associated with authenticity and quality for longer; in others, minimal and light designs may be embraced more quickly as advanced or chic. Messaging and product portfolios may need to be adapted accordingly.

In all cases, the deeper cultural shift—from equating luxury with excess to equating it with discernment and responsibility—is still unfolding. Lightweight luxury both responds to and accelerates this shift. Brands must stay attuned to consumer narratives, media discourse, and local regulatory developments to navigate the transition smoothly.

8. A 2026 Playbook for Designing Lightweight Luxury

For practitioners looking to apply these ideas, it helps to think in terms of a structured design and development roadmap suited to 2026 realities.

First, clarify the role of weight in your brand’s value proposition. Map where weight genuinely contributes to user experience (for example, a satisfying closing motion for a cap) versus where it is simply habit. Ask: if this component were lighter but more tactile, would it truly diminish perceived luxury?

Next, define your heirloom and husk strategy. Decide which categories and SKUs lend themselves best to refillable systems. Design heirloom shells that can work across product families—fragrance, skincare, color—to create a coherent ecosystem. Engineer husks that are as minimal and mono-material as possible without sacrificing functionality.

Then, embed smart lightweighting principles into your packaging development process:

- Use simulation and prototyping to identify where structural material can be removed.

- Work with suppliers who can deliver thin-wall glass, precision aluminum, and advanced polymers.

- Standardize around materials and components that align with 2026 recyclability and regulatory expectations.

Concurrently, invest in haptics. Develop a surface strategy that benefits the full range of your packaging: choose a palette of finishes (matte, frosted, stone-like, micro-embossed) that expresses your brand while providing tactile richness. Test these finishes with users to confirm that they elevate perceived quality even when weight is reduced.

Finally, integrate communication early. Plan how you will tell the lightweight luxury story—through on-pack cues, digital content, retail displays, and PR. Make sure sustainability and design teams collaborate so that claims are both compelling and accurate.

Source: https://fsc.org/en/blog/sustainable-packaging

9. Luxury Without the Luggage

As 2026 unfolds, the most forward-looking cosmetic brands treat packaging not just as a container but as a statement of values and intelligence. The old reflex—equating luxury with unnecessary mass—is giving way to a new sensibility where the best-designed objects are those that deliver maximum emotional impact with minimal physical burden.

Lightweight luxury offers a path forward. It preserves the magic of beautiful bottles, jars, and compacts, while aligning them with the constraints and aspirations of a warming, resource-constrained world. It does not ask consumers to give up sensory pleasure; it reimagines that pleasure through engineering, texture, and thoughtful systems that respect both the user and the planet.

On the vanities and in the bathrooms of 2026, this shift is already visible. Bottles that once stayed heavy through hidden glass now appear to float; metals once associated with utility now gleam with prestige; refillable shells stand as personal totems, refilled again and again with featherlight husks. The rituals of beauty endure—but they do so with less luggage and more intelligence.

FAQs

Why are luxury beauty brands moving away from heavy packaging?

Brands are responding to stricter sustainability expectations, tighter regulations on packaging waste and emissions, and rising logistics costs. Heavy, single-use packs have a higher carbon footprint and are more expensive to transport, so lighter, smarter designs help brands meet environmental targets and improve profitability.

Does lighter packaging feel cheaper to consumers?

It can, if nothing else changes. That is why 2026 designs emphasize haptics—matte, frosted, stone-like, and micro‑embossed surfaces—to provide a rich tactile experience. These textures, combined with careful proportions and finishes, help lighter packs feel just as luxurious (or more) than older heavy formats.

Are refillable luxury packages really more sustainable?

When well-designed and actually reused, refillable systems typically reduce total material use and transport emissions over the product’s lifetime. The environmental benefit depends on factors such as how many times the heirloom shell is refilled, the recyclability of the husks, and the energy used in production and logistics

Will lighter packaging compromise product protection?

Not if it is engineered correctly. Thin walls and lighter structures must go through rigorous testing for drop resistance, sealing, and barrier performance. In many 2026 designs, geometry, internal ribs, and advanced materials maintain protection even as overall weight decreases.

How do brands communicate the benefits of lighter packaging to consumers?

Brands often use simple on-pack icons, short explanations about material savings or carbon reductions, and digital content like diagrams or short videos. Many also highlight the story behind heirloom shells and show before‑and‑after visuals comparing legacy heavy packs with newer lightweight versions.

How does “Lightweight Luxury” affect the unboxing and social media experience?

Instead of focusing on a heavy “thud,” brands lean into visual drama (floating bottles, sculptural heirlooms, negative space) and tactile content (close‑ups of textures). These elements photograph and film well, making lightweight luxury packaging highly shareable while still aligning with sustainability narratives.