Light exposure is a critical factor in the preservation, efficacy, and safety of countless products. From life-saving pharmaceuticals to gourmet olive oils and luxury cosmetics, many items are vulnerable to the damaging effects of light. When exposed to ultraviolet (UV) rays and certain wavelengths of visible light, sensitive compounds can degrade, lose potency, or spoil prematurely. This makes the choice of packaging, especially the color of glass containers, a vital decision for manufacturers and brand owners.

The color of glass is not just an aesthetic choice; it plays a pivotal role in determining how much light reaches the product inside. Colored glass can block or absorb damaging wavelengths, extending shelf life and maintaining quality. In this comprehensive guide, we will explore the science behind light sensitivity, the protective qualities of different glass colors, real-world industry practices, and the future of light-resistant packaging. Whether you are a manufacturer, brand manager, or curious consumer, understanding the importance of glass color can help you make informed decisions that protect both products and reputations.

The Science of Light Sensitivity

Why Are Some Products Sensitive to Light?

Light sensitivity in products arises from the presence of ingredients that react with energy from sunlight or artificial lighting. This is especially true for substances containing organic molecules, which can absorb photons and undergo chemical changes. These changes can lead to:

Photodegradation: The breakdown of chemical compounds when exposed to light, often resulting in loss of efficacy, color fading, or the formation of harmful byproducts.

Oxidation: Light can accelerate the oxidation process, especially in oils and vitamins, leading to rancidity or loss of nutritional value.

Loss of Potency: Active ingredients in pharmaceuticals and cosmetics can lose their therapeutic or cosmetic benefits when altered by light.

Types of Light That Cause Damage

Ultraviolet (UV) Light (100–400 nm): The most damaging type, UV light can break chemical bonds and initiate rapid degradation of sensitive compounds. UVB (280–315 nm) and UVA (315–400 nm) are particularly problematic for many products.

Visible Light (400–700 nm): While less energetic than UV, visible light—especially the blue and violet end of the spectrum—can still cause significant changes in sensitive formulas.

Infrared Light (>700 nm): Primarily causes heating, which can indirectly accelerate degradation but is less of a direct concern for photodegradation.

Mechanisms of Degradation

Direct Photolysis: Absorption of light by a molecule leads directly to its breakdown.

Photo-oxidation: Light exposure in the presence of oxygen causes oxidation, a common problem in oils and vitamins.

Isomerization: Some compounds, like Vitamin A and E, can change structure (isomerize) under light, reducing their effectiveness.

Examples of Light-Sensitive Products

Pharmaceuticals: Antibiotics, hormones, and biologics are often highly sensitive to light.

Cosmetics: Products containing retinol, Vitamin C, and plant extracts degrade rapidly in light.

Food and Beverages: Olive oil, beer, and certain juices lose flavor, aroma, and nutritional value when exposed to light.

Glass as a Protective Material

Why Choose Glass?

Glass has been a preferred packaging material for thousands of years, and its enduring popularity is no accident. Its unique combination of chemical, physical, and environmental properties makes it especially well-suited for protecting light-sensitive products across industries.

Inertness: Ensuring Product Purity

One of the most important reasons for choosing glass is its chemical inertness. Glass is non-reactive with most substances, including acids, bases, and organic compounds. This means:

- No leaching: Glass does not release harmful chemicals or interact with the contents, unlike some plastics or metals, which can leach additives or react with acidic or oily products.

- Preservation of flavor, aroma, and efficacy: For pharmaceuticals, cosmetics, and foods, this ensures that the product remains pure, uncontaminated, and effective throughout its shelf life.

- Regulatory compliance: Many health and safety regulations require inert packaging for sensitive products, making glass a natural choice.

Barrier Properties: Superior Protection

Glass is an excellent barrier material:

- Impermeability: Glass is virtually impermeable to gases (like oxygen and carbon dioxide) and moisture. This is crucial for products that degrade in the presence of air or humidity.

- Protection from external contamination: Unlike many plastics, which can allow slow diffusion of gases or vapors, glass forms a complete barrier, keeping contents safe and stable.

- Consistent performance: These barrier properties do not degrade over time, ensuring long-term protection.

Recyclability: Sustainable and Eco-Friendly

Glass is one of the most sustainable packaging materials available:

- Infinite recyclability: Glass can be recycled endlessly without losing quality or purity. Recycled glass (cullet) is often used to make new containers, reducing energy use and raw material consumption.

- Environmental benefits: Using recycled glass reduces carbon emissions and landfill waste. In many countries, glass recycling rates are high, supporting circular economy goals.

- Consumer appeal: Environmentally conscious consumers and brands value glass for its “green”credentials.

Customizability: Tailored Protection

Glass offers remarkable flexibility in design to meet specific product needs:

- Color: By adding different metal oxides during manufacture, glass can be made in various colors (amber, green, cobalt blue, etc.), each offering different levels of protection against light.

- Thickness and shape: Glass containers can be made thicker for extra durability or shaped for ergonomic or branding purposes.

- Surface treatments: Glass can be coated, frosted, or printed for additional light protection, branding, or functional benefits.

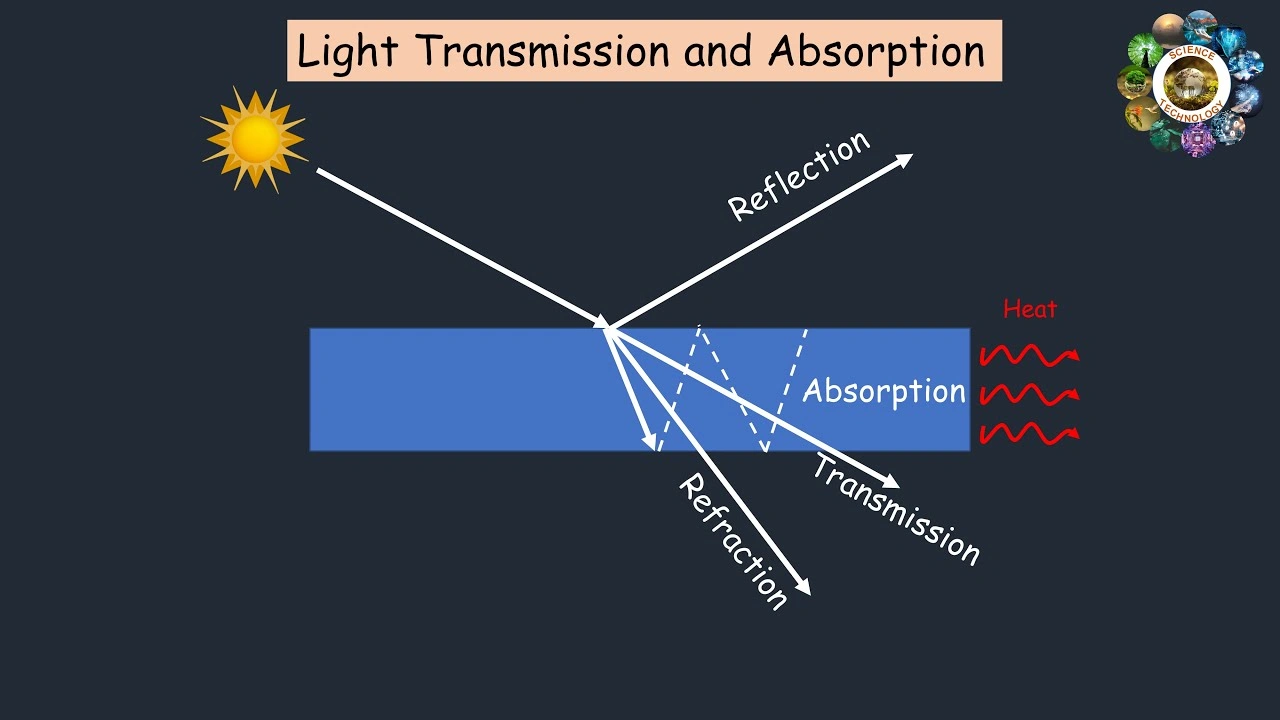

How Glass Interacts with Light

The way glass interacts with light is fundamental to its effectiveness in protecting light-sensitive products. The interaction depends on the glass’s composition, thickness, and especially its color, which is determined by the presence of specific colorants. Here’s how these properties influence the three main ways light behaves when it encounters glass:

Transmission

Transmission refers to the portion of light that passes through the glass.

- Clear glass allows most UV and visible light to pass through with minimal absorption, making it unsuitable for protecting light-sensitive products. For typical glass with a refractive index around 1.5, about 4% of incident light is reflected at each surface, and the rest is transmitted through the glass unless it is absorbed by the material itself.

- Transmittance is affected by both the composition and thickness of the glass. Thicker glass or glass with higher absorption coefficients will transmit less light. For example, a 25 mm thick sample of standard optical glass can have internal transmittance above 99% between 400 nm and 1060 nm, but this drops sharply in the UV and IR ranges due to absorption.

Absorption

Absorption occurs when photons of light have energies that match the energy required to excite electrons in the glass, causing the glass to absorb those photons.

- Colored glass (amber, green, cobalt blue, etc.) is created by adding metal oxides or other colorants during manufacturing. These additives introduce absorption bands at specific wavelengths, allowing the glass to absorb (and thus block) certain portions of the light spectrum.

–For example, amber glass absorbs most UV and blue visible light, making it ideal for protecting pharmaceuticals and light-sensitive products.

–Green glass absorbs red light almost completely, but transmits green wavelengths, which is why it appears green.

- Absorption increases with thickness: The longer the path light travels through glass, the more it is absorbed.

Reflection

Reflection happens at the glass surface when there is a change in refractive index between air and glass.

- For most glass types, about 4% of light is reflected at each interface under normal incidence.

- Reflective coatings can be applied to glass surfaces to enhance reflection of specific wavelengths, providing an extra layer of light protection for sensitive products.

The Role of Colorants

- Colorants such as iron, chromium, or cobalt oxides are added to the glass batch during manufacturing. These additives determine which wavelengths of light are absorbed or blocked by the glass, directly impacting its protective properties.

–Iron oxide gives green glass its color and absorption properties.

–Cobalt oxide produces blue glass that absorbs yellow and red light.

–Sulfur and carbon in combination with iron create amber glass, which is highly effective at absorbing UV and blue light.

- The concentration of colorants and the thickness of the glass both increase the absorption coefficient, reducing the amount of transmitted light and enhancing protection.

Glass Colors Used for Light-Sensitive Products

Amber (Brown) Glass

Historical Context

Amber glass has played a pivotal role in product preservation since the 19th century. Apothecaries and early pharmacists quickly realized that medicines stored in clear containers degraded faster, losing their potency and sometimes becoming unsafe. The switch to brown (amber) glass bottles was a breakthrough, as it dramatically extended the shelf life of tinctures, medicines, and herbal extracts. This tradition carried over into the beverage industry, where brewers found that beer stored in amber bottles was less likely to develop off-flavors when exposed to sunlight.

How Amber Glass Is Made

Amber glass gets its distinctive brown color and protective qualities from the addition of specific compounds during the glassmaking process:

- Key additives: Iron, sulfur, and carbon compounds are melted with silica (the main ingredient in glass) at high temperatures.

- Resulting color: The combination of these additives produces a rich brown hue.

- Light absorption: The chemical structure of amber glass is especially effective at absorbing light in the ultraviolet (UV) and blue visible spectrum.

Protective Properties

Amber glass is renowned for its ability to shield contents from damaging light:

- Blocks up to 99% of UV light below 450 nm. This is crucial because UV light is the most energetic and damaging part of the spectrum for many organic and pharmaceutical compounds.

- Absorbs blue and violet visible light. These wavelengths are also harmful to sensitive ingredients, accelerating photodegradation and oxidation.

- Reduces photodegradation and oxidation. By blocking these wavelengths, amber glass preserves the chemical integrity, potency, and shelf life of its contents.

Industry Applications

Amber glass is the gold standard for packaging light-sensitive products in several industries:

- Pharmaceuticals: Most prescription and over-the-counter medications, especially those with light-sensitive active ingredients, are packaged in amber glass bottles or vials. Regulatory agencies such as the FDA and EMA often require this for specific drugs.

- Essential Oils: Many essential oils, including lavender, tea tree, peppermint, and citrus oils, are highly volatile and degrade rapidly when exposed to light. Amber bottles are standard to preserve their therapeutic qualities and aroma.

- Beer and Specialty Beverages: Beer, especially those with a high hop content, is susceptible to “skunking”—a chemical reaction triggered by UV light that produces unpleasant flavors. Amber bottles significantly reduce this risk, making them the preferred choice for most breweries.

Case Studies

- Taking a high-end essence of Estee Lauder as an example, when the R&D personnel conducted stability tests, they placed the essence in ordinary plastic packaging and amber glass packaging respectively, and placed them in the same high temperature and high humidity environment. After several months, it was found that the active ingredient content of the essence in the plastic packaging decreased by about 20%, and the texture became thinner; while the active ingredient of the essence in the amber glass packaging only decreased by 3%, the texture remained stable, and it can continue to provide consumers with stable skin care effects. Since amber glass does not react with product formulas, it ensures that product ingredients are not affected by packaging, maintains product effectiveness and purity, and prevents harmful chemicals or toxins from penetrating from packaging into products, ensuring the safety of products for skin use.

- Lancome Absolu Facial Cream is packaged in amber glass jars. Experimental data show that after being placed in the same environment for 6 months, the moisture loss rate of ordinary plastic-packaged creams is 15%, while the moisture loss rate of amber glass-packaged creams is only 5%. At the same time, it can effectively prevent external dust, microorganisms and other pollutants from entering the product. Related studies have shown that the microbial contamination rate of eye serums packaged in amber glass is 80% lower than that of ordinary packaging, which greatly reduces the risk of product deterioration and ensures product safety and effectiveness. This barrier protection is particularly critical for cosmetics used around the eyes or other sensitive parts of the face.

Limitations

Despite its advantages, amber glass does have some drawbacks:

- Reduced product visibility: The deep brown color makes it difficult for consumers to see the product inside, which can be a disadvantage for items where appearance matters.

- Higher production cost: The addition of colorants and the need for specialized manufacturing processes make amber glass more expensive than standard clear glass.

Cobalt Blue Glass

How Cobalt Blue Glass Is Made

Cobalt blue glass is created by introducing cobalt oxide (CoO) into the glass batch during the manufacturing process. Even a small amount—often less than 0.1% by weight—is enough to impart a rich, deep blue hue to the glass. The cobalt ions absorb specific wavelengths of light, resulting in both the striking coloration and enhanced protective properties.

- Manufacturing process: The cobalt oxide is mixed with silica, soda, and lime (the basic ingredients of glass) and melted at high temperatures. The resulting glass is then formed into bottles, jars, or vials as needed.

- Color consistency: Cobalt blue glass maintains its color and protective qualities throughout the life of the container, as the color is distributed uniformly in the glass matrix.

Protective Properties

Cobalt blue glass provides moderate protection against harmful light, particularly in the UV and visible ranges:

- UV absorption: While not as effective as amber glass, cobalt blue glass absorbs a portion of UV rays, helping to slow the photodegradation of sensitive contents.

- Visible light absorption: Cobalt blue glass is especially effective at absorbing yellow and red wavelengths, which can contribute to the breakdown of certain organic compounds.

- Aesthetic appeal: The vivid blue color is visually striking and often associated with purity, luxury, and quality, making it a popular choice for premium products.

Industry Applications

Cobalt blue glass is chosen not only for its moderate protective properties but also for its branding and marketing potential. Common uses include:

- Cosmetics and Skincare: Many high-end brands use cobalt blue glass for packaging serums, facial oils, and perfumes. The color helps protect sensitive ingredients like essential oils, vitamins, and botanical extracts from light-induced degradation, while also creating a distinctive, upscale look.

- Essential Oils: Some aromatherapy and wellness brands prefer blue bottles as a way to differentiate their products and provide moderate light protection.

- Specialty Foods: Artisanal vinegars, gourmet oils, and other specialty foods sometimes use cobalt blue glass to stand out on shelves and suggest premium quality.

Case Studies

- Neal’s Yard Remedies: This iconic British brand is renowned for its deep blue glass bottles, used across its line of facial oils, serums, and toners. The cobalt blue glass provides moderate protection against UV and visible light, helping to shield sensitive botanicals and essential oils from UV-induced oxidation. For example, their Purifying Palmarosa Toner—formulated with witch hazel and tea tree oil—is packaged in blue glass to help preserve the integrity and fragrance of its natural ingredients, while also reinforcing the brand’s apothecary-inspired, natural identity. The distinctive blue packaging is a core element of Neal’s Yard Remedies’visual branding, signaling both product quality and a commitment to natural formulations.

- Herbivore Botanicals: Herbivore’s facial oils and serums, such as the award-winning Lapis Balancing Facial Oil, are packaged in cobalt blue glass bottles. This packaging not only helps protect the formula—which includes light-sensitive ingredients like blue tansy and jasmine—from UV degradation, but also communicates a sense of luxury and purity to consumers. Customers associate the blue bottles with quality and trust, and the brand highlights both the protective and aesthetic benefits of cobalt blue glass in its sustainability messaging and recycling instructions. The blue glass helps maintain the oil’s natural color and efficacy, even as the brand educates users about potential color shifts due to light exposure—a testament to the glass’s role in product preservation.

Limitations

Despite its advantages, cobalt blue glass has some limitations:

- Less protection than amber glass: While cobalt blue glass offers moderate UV and visible light protection, it does not block as much harmful light as amber glass. It is therefore not recommended for highly light-sensitive pharmaceuticals or products that require maximum light shielding.

- Cost: Cobalt oxide is a relatively expensive additive, making cobalt blue glass more costly to produce than clear or even some other colored glasses. This can impact the final price of the packaged product.

Green Glass

How Green Glass Is Made

Green glass is produced by adding specific metal oxides—primarily iron oxide, but also chromium and sometimes copper—to the glass batch during manufacturing. The precise combination and concentration of these additives determine the final color, which can range from a light, pale green to a rich, deep emerald.

- Iron oxide is the most common colorant and is responsible for the classic green hue seen in many beverage bottles.

- Chromium oxide can intensify the green color, producing darker shades.

- Copper oxide may be used for special tints or to achieve a bluish-green effect.

The color is distributed uniformly throughout the glass, ensuring consistent appearance and protective properties.

Protective Properties

Green glass offers minimal to moderate protection against light:

- UV absorption: Green glass absorbs some ultraviolet (UV) light, but not as effectively as amber or cobalt blue glass. It blocks a portion of the UV spectrum and some visible light, particularly in the red and blue regions.

- Visible light absorption: It allows more visible light to pass through than amber glass, which means it offers less protection for highly light-sensitive products.

- Traditional and aesthetic value: Green glass is strongly associated with traditional packaging for wine, beer, and olive oil, adding a sense of heritage and quality.

Industry Applications

The use of green glass is widespread in the food and beverage industries, particularly for products where moderate light protection and tradition are important:

- Wine Bottles: Most red wines and some white wines are packaged in green glass. The color helps reduce the risk of “ightstruck”flavors—unpleasant aromas and tastes that develop when wine is exposed to light, especially in the presence of riboflavin and amino acids.

- Beer: Many European and specialty beers are bottled in green glass. While it offers less protection than amber, it is often chosen for branding and market differentiation.

- Olive Oil: Green glass bottles help slow the oxidation process, preserving the delicate flavors, nutrients, and antioxidants in high-quality olive oils.

Case Studies

- Serums and Creams: Many skincare brands choose green glass bottles for serums and moisturizers, leveraging the glass’s ability to block a significant portion of UV light. This UV protection helps preserve sensitive ingredients s uch as plant extracts and essential oils, maintaining product potency and effectiveness throughout their shelf life. The green hue also signals eco-conscious branding, aligning with consumer preferences for environmentally friendly packaging and reinforcing the product’s natural or botanical positioning.

- Essential Oils: Green glass bottles are popular in the essential oils market because they help maintain oil potency and prevent oxidation. The UV-blocking properties of green glass slow the degradation of aromatic and active compounds, which is crucial for preserving fragrance and therapeutic benefits over time. Brands also favor green glass for its fully recyclable nature and premium appearance, supporting both sustainability goals and consumer expectations for high-quality, long-lasting packaging.

Limitations

Despite its popularity, green glass has some important limitations:

- Not suitable for highly sensitive products: Green glass does not block as much UV light as amber glass, making it unsuitable for pharmaceuticals or products with extreme light sensitivity.

- Consumer confusion: Some consumers mistakenly believe green glass offers the same level of protection as amber glass. In reality, its light-blocking ability is significantly lower.

- Aesthetic vs. functional balance: In many cases, the choice of green glass is driven more by tradition and brand image than by optimal protection.

Clear Glass

Properties

Clear glass is the most basic form of glass packaging. It is produced without the addition of colorants or metal oxides, resulting in a completely transparent material. This clarity is achieved by using highly purified sand (silica), soda ash, and limestone in the glass batch, and by minimizing impurities that could impart color.

Transparency: Clear glass allows consumers to see the product inside, making it ideal for showcasing color, texture, and clarity.

Neutral appearance: Its lack of color makes it versatile for a wide range of branding and labeling options.

Protective Properties

- No meaningful protection: Clear glass transmits nearly all ultraviolet (UV) and visible light, offering little to no shielding for the contents. This means that any product sensitive to light will be exposed to potentially harmful rays, accelerating degradation.

- Maximum product visibility: The key benefit of clear glass is its ability to display the product’s appearance, which is highly valued for items where visual appeal influences purchasing decisions.

Industry Applications

Clear glass is widely used across industries, particularly where product stability is not compromised by light exposure or where rapid turnover ensures minimal risk:

- Water and Spirits: Bottled water, vodka, gin, and other clear spirits are often packaged in clear glass. These products are generally not light-sensitive, or are consumed quickly enough that light exposure is not a significant concern.

- Display Items: Decorative bottles, limited-edition collectibles, and product samples frequently use clear glass to highlight unique colors or artistic designs.

- Vinegar and Syrups: Many vinegars, simple syrups, and other stable condiments are sold in clear glass, as their shelf stability is not affected by light.

Case Studies

- Jams & Balms with Botanical Inclusions: Many modern skincare brands package floral-infused oils, balms, and gel-based products in clear glass containers to visually showcase suspended botanicals, petals, or shimmering textures. For example, products like rose petal-infused facial oils or calendula balms are often displayed in transparent jars or bottles, allowing consumers to appreciate the natural beauty and artisanal quality of the ingredients. These formulations are typically designed for rapid use or contain antioxidants and stabilizers to help offset the effects of light exposure, ensuring the product remains effective and attractive during its intended shelf life.

- Premium Face Masks and Scrubs: Clear glass jars are commonly used for colorful or textured face masks and exfoliating scrubs. Brands such as Herbivore Botanicals and Fresh use clear packaging to highlight the vibrant hues and unique consistencies of their products—think pink clay masks or sugar scrubs with visible fruit seeds. To mitigate potential light-induced degradation, these products are often accompanied by consumer guidance such as “store away from direct sunlight”or are intended for quick use after opening. The visual appeal of clear glass helps drive consumer interest and purchasing decisions, especially in boutique and luxury skincare markets.

Limitations

Despite its popularity and visual appeal, clear glass has significant drawbacks for light-sensitive products:

- Accelerates degradation: Because it provides no meaningful barrier to UV or visible light, clear glass can accelerate the breakdown of sensitive ingredients, leading to loss of flavor, color, aroma, or nutritional value.

- Shorter shelf life: Products stored in clear glass may lose their desired qualities more quickly compared to those in colored glass, especially if exposed to sunlight or strong artificial lighting.

- Not suitable for sensitive items: Clear glass should be avoided for pharmaceuticals, essential oils, and other products that degrade rapidly in light.

Specialty and Other Colors

Rare Colors

Red and Purple Glass: Used for niche products or branding differentiation. These colors offer some light protection but are less common due to cost and limited availability.

Multi-layered or Coated Glass: Some manufacturers are experimenting with laminated or coated glass that combines multiple protective layers for enhanced performance.

Industry Innovations

Smart Glass: Incorporates sensors or color-changing properties to indicate exposure or spoilage.

UV-Blocking Coatings: Applied to clear or colored glass to further reduce light transmission.

Comparative Table: Glass Colors and Their Protective Properties

| Glass Color | UV Protection | Visible Light Protection | Typical Uses | Aesthetic Appeal | Product Visibility |

| Amber | High | High (esp. blue light) | Pharma, essential oils, beer | Moderate | Low |

| Cobalt Blue | Medium | Medium | Cosmetics, specialty foods | High | Medium |

| Green | Low–Medium | Low | Wine, beer, olive oil | Moderate | High |

| Clear | None | None | Water, vinegar, spirits | High | High |

Factors to Consider When Selecting Glass Color

Product Sensitivity

High Sensitivity: Pharmaceuticals, essential oils, and some cosmetics require maximum protection—amber glass is recommended.

Moderate Sensitivity: Specialty foods and beverages can use cobalt blue or green glass.

Low Sensitivity: Products with short shelf life or low risk of degradation can use clear glass.

Shelf Life and Storage Conditions

- Long-Term Storage:

If your product is intended for extended shelf life or will be exposed to strong retail or warehouse lighting, opt for glass colors with higher UV-blocking capabilities (amber or, to a lesser extent, cobalt blue/green).

- Short-Term Use or Controlled Lighting:

For products meant for quick consumption or display in low-light environments, clear glass may suffice.

Brand Image and Marketing

- Luxury Brands:

High-end or boutique brands often choose cobalt blue, deep green, or other specialty colors to create a premium, distinctive look that stands out on shelves and communicates exclusivity.

- Traditional Brands:

Brands with a heritage or artisanal focus frequently use green or amber glass to evoke authenticity and trust, especially in categories like wine, beer, and apothecary-style skincare.

Consumer Preferences

- Visibility:

Some consumers prefer packaging that allows them to see the product’s color, texture, or inclusions. For these markets, clear or lightly tinted glass enhances appeal, especially for visually striking products like floral-infused oils or colorful face masks.

- Perceived Quality:

Colored glass is often associated with higher quality and protection. Surveys show that consumers view products in amber, blue, or green glass as more premium and trustworthy, particularly in cosmetics and specialty foods.

Cost and Availability

- Amber and Cobalt Blue Glass:

These options are generally more expensive due to the cost of colorants (like iron, cobalt, or chromium oxides) and specialized production processes. They may also have longer lead times or limited availability depending on region and supplier.

- Clear Glass:

The most widely available and cost-effective option, clear glass is less expensive to produce but offers no light protection. It is suitable for products where protection is not a priority or where cost is a primary concern.

Limitations and Future Trends

Limitations of Colored Glass

While colored glass offers significant advantages in protecting light-sensitive products, it is not without its drawbacks. Understanding these limitations is crucial for manufacturers, brands, and consumers alike.

Cost

- Production Costs: The addition of metal oxides and other colorants (such as iron, cobalt, or chromium) increases the manufacturing cost of colored glass compared to clear glass. Specialized production lines and quality control for color consistency can also add to expenses.

- Transportation: Colored glass, especially thicker or specialty bottles, tends to be heavier, increasing shipping costs and carbon footprint.

Recycling Complexity

- Sorting Requirements: For effective recycling, glass must be sorted by color. Mixing colors can compromise the quality of recycled glass (cullet) and limit its applications.

- Infrastructure Challenges: Not all recycling facilities are equipped to handle multiple glass colors, which can lead to more waste if colored glass is not properly sorted and processed.

- Market Demand: There is often less demand for recycled colored glass compared to clear glass, which is more versatile for remanufacturing.

Limited Protection

- Incomplete Light Blocking: Even the most protective colored glass (such as amber) cannot block all wavelengths of light. Some UV and visible light may still penetrate, especially if the glass is thin or the exposure is prolonged.

- Need for Additional Barriers: Extremely light-sensitive products—such as certain pharmaceuticals, biologics, or advanced skincare actives—may require additional protective measures, such as secondary packaging (cartons), UV-blocking coatings, or storage in dark environments.

Future Trends

As the packaging industry evolves, several promising trends are emerging to address the limitations of colored glass and further enhance product protection, sustainability, and consumer engagement.

Advanced Coatings

- UV-Blocking Coatings: New transparent coatings can be applied to the surface of glass containers to significantly enhance UV protection without changing the appearance of the glass. This allows brands to use clear or lightly tinted glass while still protecting sensitive contents.

- Functional Coatings: Some coatings also offer anti-microbial, anti-fingerprint, or scratch-resistant properties, improving both product safety and consumer experience.

Smart Packaging

Integrated Sensors: Smart packaging technologies are being developed that incorporate sensors or color-changing indicators into glass containers. These can alert consumers or retailers if a product has been exposed to excessive light, heat, or has reached the end of its shelf life.

Traceability and Authentication: QR codes, RFID chips, and blockchain integration are being used to track product history, ensure authenticity, and provide consumers with information about proper storage and usage.

Sustainability

- Lightweight Glass: Advances in glass manufacturing are enabling the production of lighter yet durable containers, reducing material use and transportation emissions.

- Recycled Content: There is a growing emphasis on increasing the percentage of recycled glass (cullet) in new containers, supporting circular economy goals.

- Biodegradable and Eco-Friendly Coatings: Research is ongoing into coatings and additives that are biodegradable or derived from renewable resources, further reducing the environmental impact of glass packaging.

Regulatory Developments

- Updated Guidelines: As scientific understanding of photodegradation and product stability improves, regulatory agencies (such as the FDA and EMA) are likely to update packaging requirements. This could lead to broader adoption of protective glass colors, advanced coatings, and stricter labeling for light-sensitive products.

- Global Harmonization: Efforts are underway to standardize packaging regulations across regions, making it easier for brands to comply and ensuring consistent product protection worldwide.

Conclusion

The color of glass used in packaging is far more than a matter of aesthetics—it is a critical factor in product preservation, safety, and consumer satisfaction. Amber glass remains the gold standard for protecting highly light-sensitive products, especially in the pharmaceutical and essential oil industries. Cobalt blue and green glass offer a balance of protection and visual appeal, making them popular in cosmetics, specialty foods, and beverages. Clear glass, while attractive and versatile, is best reserved for products that do not require light shielding.

As technology advances, expect to see more innovative solutions, from advanced coatings to smart packaging, that further enhance product safety and sustainability. Manufacturers and brand owners must carefully assess product sensitivity, regulatory requirements, and market positioning when selecting glass packaging. The right choice not only preserves product quality but also supports brand integrity and consumer trust.

For anyone involved in product development or packaging, understanding the science and strategy behind glass color selection is essential. By making informed choices, you can ensure that your products reach consumers in optimal condition, maintaining their intended benefits and value.