1. Introduction – The False Trade-Off Between Sustainability, Premium Feel, and Cost

For many beauty and personal care brands, sustainable plastic packaging still feels like a compromise.

Choose sustainability, and you risk losing visual impact, tactile quality, or cost control.

Choose aesthetics and scalability, and sustainability becomes a secondary checkbox.

This perceived trade-off is one of the biggest reasons why sustainable plastic initiatives stall after the first prototype. The issue, however, isn’t plastic itself — nor is it sustainability. The issue lies in how sustainability gets defined, evaluated, and executed throughout the packaging development process.

In real-world projects, sustainable plastic packaging must perform on multiple levels at once. It needs to communicate brand value at first glance, function reliably across global supply chains, remain compatible with formulations, scale consistently in mass production, and still meet evolving environmental expectations. When any one of these dimensions gets treated in isolation, the result is often higher cost, lower quality, or both.

This article is written for brands that want to move beyond surface-level eco claims and make sustainable plastic packaging work in practice. Rather than focusing on a single “best material,” we’ll explore how material choice, structural design, manufacturing strategy, and long-term planning come together to create packaging that’s both responsible and commercially viable.

Sustainability without compromise isn’t a shortcut. It’s a process — and when done right, it becomes a competitive advantage rather than a limitation.

2. Why “Sustainable Plastic” Often Disappoints in Real Projects

Sustainability Defined Only by Material, Not by System

One of the most common mistakes brands make is defining sustainability purely by material labels: PCR content, biodegradable claims, or recycled symbols. While these indicators matter, they rarely tell the full story.

Packaging exists within a system — design, production, logistics, usage, and end-of-life. A bottle with high PCR content but poor structural stability may require thicker walls, secondary packaging, or higher rejection rates during production. In such cases, the overall environmental footprint may increase rather than decrease.

The beauty packaging industry in 2026 recognizes this systems-thinking approach as essential. Brands are increasingly prioritizing mono-material packaging designs that allow consumers to recycle products more easily and help brands meet Extended Producer Responsibility (EPR) and Packaging and Packaging Waste Regulation (PPWR) obligations, particularly in European markets.

True sustainability begins with system-level thinking, not material selection alone. This includes evaluating the entire lifecycle: raw material extraction, manufacturing energy requirements, transportation impacts, consumer use patterns, and realistic end-of-life scenarios based on existing recycling infrastructure.

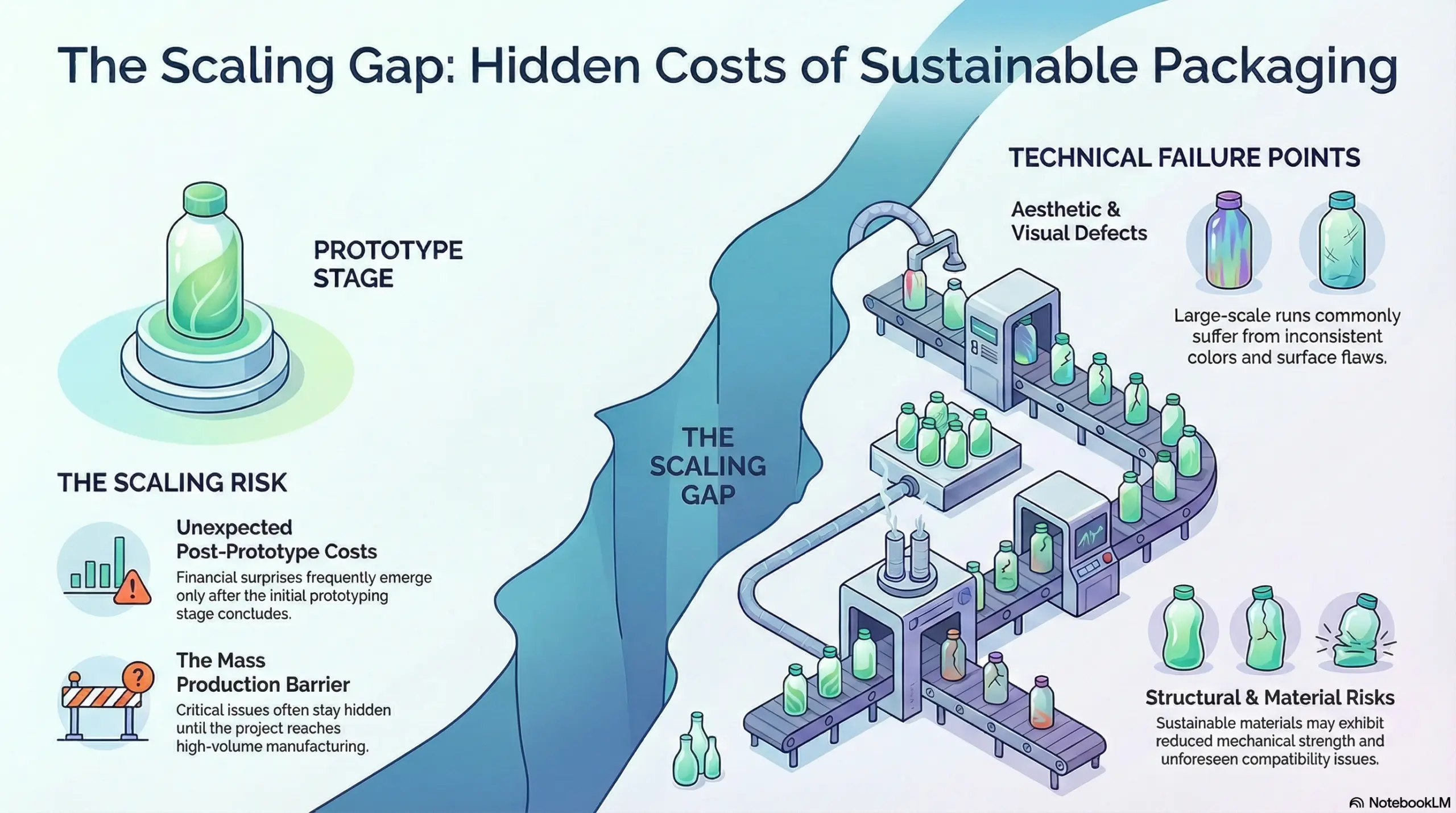

The Hidden Cost of Poor Material–Design Matching

Many sustainability-driven projects encounter unexpected costs after the prototype stage. Color inconsistency, surface defects, reduced mechanical strength, or compatibility issues often emerge only during scale-up.

These problems usually stem from a mismatch between material characteristics and packaging design. Sustainable plastics behave differently during molding, finishing, and decoration. When design doesn’t account for these behaviors early on, the cost of correction becomes significantly higher downstream.

PCR plastics, for instance, can show considerable color variations ranging from yellow to white to green shades due to their diverse post-consumer sources. These inherent color differences affect how well pigments disperse within the polymer matrix, potentially leading to inconsistent color dispersion that impacts both aesthetics and mechanical properties. Overcompensating by adding more pigment to fix color issues can compromise the structural integrity of the plastic package.

This is why experienced manufacturers insist on aligning material decisions with structural and tooling strategies from the beginning. Early-stage material testing, understanding PCR supplier resin sources, and utilizing color technology specifically designed to account for these inconsistencies can prevent costly mid-project corrections.

When Eco Claims Undermine Perceived Brand Value

Another frequent concern is that sustainable plastic packaging “looks cheap.” In reality, this perception is rarely caused by the plastic itself. It’s more often the result of untreated surfaces, generic forms, or overcompensating eco visuals that conflict with brand positioning.

Premium perception comes from proportion, balance, surface quality, and tactile feedback — all of which are design-led factors. The 2026 cosmetic packaging trend emphasizes “lightweight luxury,” where brands are replacing heavy materials with smart design that emphasizes haptic textures and refined structural engineering rather than material weight.

Sustainable plastics can support high-end aesthetics when these elements are intentionally engineered rather than treated as afterthoughts. The key lies in understanding that eco-design is becoming the new aesthetic standard, where visual appeal and sustainability are no longer opposing forces but complementary design objectives.

3. Material Choices That Balance Sustainability and Premium Aesthetics

PCR Plastics: How Much Is Too Much?

Post-consumer recycled (PCR) plastics are widely used to improve sustainability profiles, but higher PCR content doesn’t automatically equal better results.

As PCR ratios increase, brands may encounter greater variation in color tone, surface texture, and mechanical performance. At moderate levels, these variations can be managed through controlled sourcing, formulation adjustments, and surface treatments. Beyond certain thresholds, however, costs rise sharply due to increased rejection rates and processing complexity.

The cost gap between virgin and PCR plastics remains a significant barrier to widespread adoption. An increase in corporate sustainability commitments and government regulations has driven up demand for recycled content, pressuring supply and contributing to PCR price increases. PCR production lacks the economies of scale evident in virgin material production, which makes the price gap even wider.

Long-term contracts represent one strategy for managing price volatility, as virgin and recycled plastic prices move differently across seasons. Additionally, PCR availability varies significantly by plastic type — most curbside recycling systems only accept rigid plastics #1 (PET) and #2 (HDPE), making it challenging to source PCR for other types like #5 (PP), commonly used in pumps and caps.

The key isn’t maximizing PCR percentage, but optimizing it based on brand expectations, product category, and production scale. For brands committed to transparency, understanding the specific PCR percentage that balances performance, cost, and environmental benefit creates more authentic sustainability narratives than simply pushing for the highest possible number.

Mono-Material vs. Multi-Material Structures

From a recyclability perspective, mono-material packaging often outperforms complex composite structures. Mono-material packaging refers to packaging made entirely from a single type of material, such as PET, PE, or PP.

This singular material approach simplifies the recycling process because the packaging doesn’t need sorting into different material components at material recovery facilities before processing. Multi-material packaging, conversely, is more difficult to recycle and will likely be incinerated or sent to landfills.

Mono-material packaging enables the entire unit to be recycled together without requiring consumers or recycling facilities to separate parts. It reduces contamination in recycling streams, improving the quality and value of recycled material, and simplifies sorting at materials recovery facilities (MRFs), making recycling operations more efficient.

However, mono-material solutions must still meet functional requirements such as barrier protection, durability, and user experience. In many cases, simplifying structures — rather than changing materials — yields greater sustainability gains. Removable pumps, snap-fit components, or compatible closures can dramatically improve recyclability without sacrificing performance.

A practical example comes from recent EU regulations: beginning in July 2025, all plastic beverage bottles up to three liters must come with a cap that remains attached to the bottle after opening. This regulation spurred advancements in tethered caps, including the development of clear PET caps for clear PET bottles, using the same polymer for both cap and container to avoid separation requirements at recycling centers.

For beauty and personal care packaging, similar design thinking applies. An all-PE package (PE tube with PE cap) or all-PP package (PP stick with PP insert) ensures the entire component can be recycled together.

Surface Treatments That Elevate Sustainable Plastics

Surface finishing plays a crucial role in bridging sustainability and aesthetics. Techniques such as matte texturing, soft-touch coatings, controlled gloss, or selective metallization can elevate recycled plastics to premium standards.

The challenge lies in ensuring that these finishes remain compatible with sustainability goals and don’t compromise recyclability or production efficiency. Water-based barrier coatings represent one sustainable approach that delivers resistance to moisture, oil, grease, and oxygen while maintaining recyclability. These coatings can be applied directly to surfaces without undermining the ability to recycle the base material.

Advanced coating technologies are eliminating problematic substances like PFAS (per- and polyfluoroalkyl substances) and polyethylene laminates while delivering equivalent performance. Sustainable barrier coatings now include polyhydroxy alkanoates (PHA), polylactic acid (PLA), waxes and wax blends, proteins, cellulose and chitosan, starch, water-based polymer dispersions, polyvinyl alcohol (PVOH), and plant-based coatings.

The trend is shifting toward simpler, single-material solutions such as water-based coatings applied directly to plastic surfaces. These can deliver premium aesthetics without undermining recyclability or compostability, and materials that work with existing recovery systems are increasingly being viewed as more viable long-term.

Early collaboration between designers and manufacturers is essential to strike the balance between aesthetic ambition and sustainability performance. Surface treatments should be considered during the initial design phase rather than applied as an afterthought to correct aesthetic deficiencies.

Choosing the Right Plastic for the Right Product

Different plastics offer different sustainability and aesthetic trade-offs. PP (polypropylene), PET (polyethylene terephthalate), PE (polyethylene), and ABS (acrylonitrile butadiene styrene) each respond differently to PCR integration, surface finishing, and long-term use.

PET is widely recyclable and commonly used for bottles and jars, with established recycling infrastructure making it one of the more sustainable options when designed as mono-material. PP offers good chemical resistance and is increasingly available in PCR form, though recycling rates lag behind PET. PE provides excellent flexibility and is suitable for tubes and squeeze bottles, with HDPE (#2) being widely accepted in curbside recycling.

Rather than asking which plastic is “most sustainable,” brands should ask which material best supports their product lifecycle, visual language, and operational realities. This requires considering formulation compatibility, required barrier properties, mechanical strength requirements, decoration techniques, and end-of-life infrastructure available in target markets.

4. Design Is the Real Differentiator, Not the Material

Structural Design as a Sustainability Lever

Material reduction through intelligent structural design is often more impactful than material substitution alone. Optimized wall thickness, reinforced stress points, and geometry-driven strength can significantly reduce material usage without compromising durability.

This approach, known as lightweighting, has become a key sustainability strategy in 2026. By reducing the amount of material required for each package while maintaining structural integrity, brands simultaneously reduce raw material consumption, lower transportation emissions due to reduced weight, and decrease production energy requirements.

Well-designed structures also improve production yield and reduce energy consumption during molding. When packaging geometry is optimized for the manufacturing process, molding cycles become more efficient, reject rates decline, and overall production costs decrease even as environmental performance improves.

Advanced computer-aided design (CAD) and finite element analysis (FEA) enable designers to identify exactly where material is structurally necessary and where it can be removed without compromising performance. This precision engineering approach transforms sustainability from a constraint into an optimization opportunity.

Tactile Experience: Weight, Balance, and Closure Feel

Premium perception is largely tactile. The way a bottle sits in the hand, the resistance of a pump, or the sound of a closure contributes more to perceived value than the material label itself.

These qualities are achieved through structural engineering and tolerance control, not through expensive materials. The 2026 trend toward “lightweight luxury” demonstrates that consumers increasingly associate premium quality with refined design and haptic feedback rather than sheer weight.

A well-balanced container with precisely engineered closure mechanisms communicates attention to detail and quality. The click of a cap, the smooth operation of a pump, the satisfying resistance when opening a jar — these sensory experiences create emotional connections that material composition alone can’t achieve.

This represents an opportunity for sustainable packaging: by investing in precision engineering and user experience design, brands can create packaging that feels luxurious despite using less material or incorporating recycled content. The perception of quality shifts from material abundance to design sophistication.

Visual Simplicity That Reduces Environmental Impact

Minimalist design isn’t just a visual trend — it’s a sustainability strategy. Fewer components, cleaner forms, and restrained decoration reduce material usage, simplify production, and enhance recyclability.

Simplicity, when executed with precision, communicates confidence and sophistication. Brands increasingly recognize that visual restraint — rather than elaborate decoration — aligns with both contemporary aesthetic preferences and environmental objectives.

Reducing decorative elements also addresses practical sustainability concerns. Multi-layer labels, metallic hot stamping, and complex printing processes can complicate recycling. Coatings that create visual effects may prevent recyclability if they’re not compatible with standard recycling processes.

By embracing clean design with minimal decoration, brands can achieve several objectives simultaneously: reduced material consumption, simplified production processes, enhanced recyclability, lower costs, and alignment with contemporary design aesthetics that value authenticity and transparency.

5. Cost Control: Where Sustainable Packaging Really Gets Expensive

Tooling and Mold Strategy for Sustainable Plastics

Tooling decisions made early in development have long-term cost implications. Sustainable plastics often require tighter process control, making mold quality and design more critical.

The cost of custom molds varies significantly based on complexity and component count. PET blow molds range from approximately $1,200 for 2-cavity molds to negotiable pricing for multi-cavity configurations. Injection molds for PET or PP bottles range from $7,000 to $40,000 based on size, wall thickness, and finish precision.

Pump head molds present particular complexity, as a typical pump head consists of 6–8 parts including collar, actuator, spring housing, and gasket seat. If all parts use 16-cavity molds, total tooling cost may reach $120,000 or more. Most brands, however, only customize 2 components (such as actuator and threaded collar), which reduces cost to $12,000–$15,000.

According to industry-standard formulas, mold pricing breaks down like this: raw materials (steel, aluminum, standard components) at 15–30%, design and CAD engineering at 10–20%, CNC machining and labor at 40–50%, polishing, texturing, and surface finish at 5–10%, and trial runs, quality checks, and packaging at 5–10%.

Higher precision molds used for airless pumps or click-on caps may cost more due to tighter tolerances and surface polish requirements. Mold amortization typically becomes profitable after producing 50,000–100,000 units.

Investing in adaptable tooling strategies enables future material adjustments without repeated redevelopment costs. As PCR availability and formulations improve, brands with flexible tooling can adjust material specifications without expensive mold redesigns.

Color Matching and Batch Stability Costs

Color consistency is one of the most underestimated cost drivers in sustainable plastic packaging. Variability in recycled content can affect pigmentation and surface appearance across batches.

Unlike virgin material with consistent color parameters, PCR inherently comes from multiple sources in most cases and can have considerable color differences. These variations affect how well color disperses within the polymer matrix.

Irregular shapes in PCR materials make this problem worse — irregular pellets melt at different rates compared to consistent shapes, causing color to disperse unevenly. When natural pellets in round form are combined with strand-cut PCR pellets, even slight melting rate differences create color dispersion problems.

Achieving consistent coloring is often hindered by the varying quality of recyclate and different processing techniques. Color will vary strongly in recyclate due to the uneven mix of post-consumer materials in typical waste streams.

Addressing this challenge requires experience, controlled sourcing, and realistic expectations set early in the project. Lab testing of chosen PCR sources, understanding PCR supplier resin sources, and utilizing color technology that uses different dispersion technologies specifically designed to account for inconsistencies can help overcome color matching challenges.

Brands should anticipate that PCR-based packaging may require broader color tolerance ranges compared to virgin plastics, or may need strategic color choices (such as darker colors that mask variability more effectively than lighter shades) to maintain consistency across production runs.

Scaling from Pilot Runs to Mass Production

Many sustainable packaging concepts perform well in limited runs but encounter issues during scale-up. What works at 5,000 units may not work at 500,000.

Scalability must be validated from the beginning — not treated as a secondary concern. Prototype runs using hand-finished samples or low-volume molds may not reveal issues that emerge when production speeds increase, cavity counts expand, or cycle times compress.

During scale-up, temperature control becomes more critical, material flow patterns change, cooling rates vary, and quality control challenges multiply. PCR materials can be particularly sensitive to these variables, showing acceptable performance in controlled pilot conditions but exhibiting greater variability under full production conditions.

Brands should involve manufacturing partners early in development to conduct scalability assessments. This includes testing proposed materials and designs under production-representative conditions, identifying potential bottlenecks before committing to full tooling, and building contingency plans for material or design adjustments based on scale-up results.

The most successful sustainable packaging projects incorporate staged validation: prototype testing, pilot production runs, scaled pilot runs, and then full production. Each stage reveals different challenges, and addressing issues incrementally prevents expensive corrections after full-scale launch.

6. Testing, Compatibility, and Long-Term Performance

Formula Compatibility and Migration Risks

Sustainable plastics must remain compatible with cosmetic formulations over time. Migration testing, stress testing, and simulated aging are essential to ensure product safety and stability.

Migration testing involves assessing whether harmful substances from packaging materials can transfer into cosmetic products during storage and use. The testing protocol typically follows stringent guidelines outlined in international standards such as ISO 21978-3:2015 and ASTM D6401.

Overall migration tests quantify chemical non-volatile substances migrating from packaging into cosmetics, typically with a limit of 10 mg per dm². Specific migration testing identifies particular substances like monomers or substances of high concern including phthalates, PAHs, bisphenol A, melamine, acetaldehyde, plastic additives, formaldehyde, and heavy metals.

Packaging compatibility refers to how well cosmetic packaging materials interact — or don’t interact — with the cosmetic formulation they contain. Several packaging compatibility tests are performed to evaluate suitability, including stability tests under real-time and accelerated conditions, chemical compatibility tests for detecting chemical interaction or attacks, biological compatibility assessments to ensure ingredient safety, physical compatibility checks to identify issues like deformation or leakage, and barrier property tests to measure resistance to UV light, oxygen, or moisture.

When incorporating PCR content or alternative sustainable materials, compatibility testing becomes even more critical. Recycled plastics may contain trace contaminants or have different permeability characteristics compared to virgin materials, potentially affecting formulation stability over the product’s intended shelf life.

Brands should conduct migration testing early in development, using actual cosmetic ingredients to simulate the final product’s chemical composition accurately. This proactive approach prevents costly recalls and protects consumer safety while building brand trust through transparent safety testing processes.

Mechanical Strength and Drop Resistance

Environmental responsibility doesn’t excuse performance failure. Packaging must withstand transportation, handling, and consumer use without increased breakage or waste.

Drop resistance testing determines how well a package can absorb shock and impact when dropped from various heights. Products inevitably fall during handling or use, making drop resistance testing crucial. Packaged products are placed on the support arm of a drop tester and subjected to free fall tests from specified heights.

Testing protocols typically include adjustable drop heights, rigid steel base platforms, clamp mechanisms to hold samples, and capability for corner, edge, and flat drop tests. Multiple drops at different orientations complete one test cycle.

After performing drop tests, several parameters are analyzed: deformation of the package, integrity of sealing elements, damage to internal components, and effect on the product inside. In many industries, passing drop resistance testing is mandatory for product shipment, especially in international logistics.

For sustainable plastic packaging incorporating PCR content or lightweighted structures, mechanical strength testing validates that environmental benefits haven’t compromised functional performance. If structural optimization has reduced wall thickness or material volume, drop testing confirms that the package maintains adequate protection throughout its lifecycle.

Impact resistance testing using dart impact testers or falling ball impact methods determines the energy required to tear or fracture packaging materials under specified conditions. This testing prevents damage to packaging surfaces due to insufficient material toughness and avoids product damage from poor impact resistance during circulation.

Shelf Life, Refilling, and Reusability

True sustainability considers longevity. Durable designs that support refilling or reuse extend the packaging lifecycle and reduce overall environmental impact.

The Ellen MacArthur Foundation estimates that replacing single-use packaging with refillable options could reduce the beauty sector’s global greenhouse gas emissions by up to 70%. Several brands have embraced refillable concepts, with L’Occitane and The Body Shop offering refill stations in Europe, North America, and Asia, allowing consumers to replenish products directly into existing containers.

L’Occitane’s in-store refill stations, available in over 1,000 stores globally, reduce plastic waste by 65% according to the brand’s sustainability reports. Infrastructure expansion represents a key trend, with The Body Shop operating 800+ refillable stations globally by 2024.

However, maintaining infrastructure for a refillable products model poses financial and logistical challenges, limiting broader adoption. The primary hurdle for true circularity lies in building the infrastructure to efficiently return, clean, and refill containers. Various refill models exist, from in-store to home-based, each presenting unique logistical challenges.

For packaging designed for reuse, durability requirements exceed single-use standards. Materials must withstand multiple use cycles, repeated cleaning, and extended exposure to formulations without degradation. Closure mechanisms must maintain integrity through numerous open-close cycles. Surface finishes must resist wear from handling.

Brands should consider hybrid approaches: packaging designed for extended single use (premium durability without requiring return infrastructure) or modular systems where certain components are reusable while others are recyclable refills. These approaches provide sustainability benefits without the full complexity of closed-loop refill systems.

7. Building a Sustainable Plastic Packaging Strategy That Lasts

Aligning Packaging with Brand Positioning

Not every brand needs the most extreme sustainability solution. The right approach is the one that aligns with brand values, customer expectations, and operational capabilities.

A prestige beauty brand targeting luxury consumers may prioritize refillable glass primary packaging with minimal plastic components, emphasizing longevity and timeless design. A mass-market brand focused on accessibility may emphasize maximum PCR content in affordable mono-material formats with clear recycling instructions. A natural/organic brand may explore bio-based plastics or alternative materials that align with ingredient sourcing narratives.

Sustainability positioning should be authentic and substantiated. In 2026, consumers and regulators increasingly scrutinize environmental claims, making “greenwashing” both ineffective and risky. Technology-enabled transparency through QR codes linking to environmental data, sourcing origins, and recycling instructions supports circularity by strengthening connections between brands and consumers beyond the shelf.

The most successful sustainability strategies integrate environmental performance into broader brand narratives rather than treating it as isolated messaging. When packaging sustainability aligns with ingredient sourcing, manufacturing practices, and corporate values, it reinforces brand authenticity rather than appearing as opportunistic trend-following.

Working with Manufacturers Early in the Design Phase

Early collaboration reduces cost, shortens development cycles, and improves outcomes. When manufacturers are involved from concept stage, sustainability becomes integrated rather than imposed.

This is where ODM (Original Design Manufacturer) and OBM (Original Brand Manufacturer) capabilities create real value — translating brand intent into manufacturable, scalable solutions. Experienced manufacturers bring practical knowledge about material behavior, tooling requirements, production constraints, and quality control methods that pure design agencies may lack.

Early manufacturer involvement enables several advantages: material selection informed by production realities, design optimized for manufacturing efficiency, tooling strategies that accommodate future adjustments, realistic cost projections based on actual production parameters, and proactive identification of potential scalability issues.

The traditional sequential approach — where brands finalize designs before approaching manufacturers — often results in expensive redesigns when production realities contradict design assumptions. Collaborative development from early concept stages prevents these disconnects.

Manufacturers with sustainability expertise can also guide brands toward certifications and standards that validate environmental claims. APR (Association of Plastic Recyclers) certification verifies that packaging meets strict criteria to ensure it can be successfully sorted, reclaimed, and reprocessed within existing recycling infrastructure. GRS (Global Recycled Standard) certification validates the use of recycled materials and ensures full traceability throughout the supply chain.

From Compliance to Competitive Advantage

When executed strategically, sustainable plastic packaging strengthens brand credibility, reduces long-term risk, and enhances market differentiation.

Regulatory landscapes continue evolving, with European PPWR requirements, extended producer responsibility mandates, and recycled content minimums expanding globally. Brands that proactively adopt sustainable packaging strategies position themselves ahead of regulatory requirements rather than scrambling to achieve compliance when deadlines arrive.

Beyond compliance, sustainability performance increasingly influences purchasing decisions. Consumer research consistently shows growing preference for brands demonstrating authentic environmental commitment. While willingness to pay premiums for sustainability varies by category and market, brand loyalty and positive perception clearly correlate with credible sustainability initiatives.

Sustainable packaging also mitigates supply chain risks. As virgin plastic prices fluctuate with petroleum markets and regulatory pressures increase on single-use plastics, brands dependent on conventional packaging face greater uncertainty. Diversified material strategies incorporating PCR, mono-material designs, and refillable options provide resilience against market disruptions.

Competitive differentiation through sustainability becomes particularly valuable in saturated categories where product formulations offer limited differentiation opportunities. When competing products deliver similar functional benefits, packaging sustainability can influence brand selection.

The long-term value of sustainable packaging extends beyond immediate cost calculations. Reduced material usage lowers ongoing production costs, enhanced brand reputation supports premium positioning, regulatory preparedness prevents expensive emergency redesigns, and supply chain resilience protects against material availability disruptions.

8. Conclusion – Sustainability Without Compromise Is a Process, Not a Shortcut

Choosing sustainable plastic packaging without sacrificing aesthetics or cost isn’t about finding a perfect material. It’s about aligning material science, structural design, manufacturing expertise, and brand strategy into a coherent system.

The beauty and personal care industries in 2026 have moved beyond viewing sustainability as an optional enhancement or marketing angle. It’s become a structural pillar of packaging development, driven by regulatory requirements, consumer expectations, and long-term business resilience.

Brands that succeed in this space don’t chase trends — they build partnerships, test assumptions early, and design with scale in mind. They recognize that sustainable packaging decisions involve complex trade-offs requiring expertise across multiple disciplines: materials engineering, structural design, manufacturing processes, supply chain logistics, regulatory compliance, and consumer behavior.

The perceived trade-off between sustainability, aesthetics, and cost exists primarily when these dimensions get addressed sequentially rather than holistically. When integrated from project inception, sustainability constraints often drive innovation that simultaneously improves environmental performance, reduces costs through material efficiency, and enhances aesthetics through thoughtful design.

Material selection matters, but it represents only one component of sustainable packaging strategies. Structural optimization, surface treatments, manufacturing processes, quality control, compatibility testing, and end-of-life planning all contribute equally to packaging sustainability outcomes.

The shift toward mono-material designs, increased PCR content, refillable systems, and lightweighting strategies demonstrates industry recognition that multiple pathways toward sustainability exist. No single approach suits all brands, categories, or markets. The most effective strategy aligns with specific brand positioning, operational capabilities, and market contexts.

As recycling infrastructure improves, material technologies advance, and regulatory frameworks mature, the practical options for sustainable plastic packaging will continue expanding. Brands investing in flexible, adaptable packaging platforms position themselves to incorporate these improvements without requiring complete redesigns.

Sustainability then becomes not a constraint, but a foundation for smarter, more resilient packaging solutions. It drives material efficiency that reduces costs, encourages design clarity that strengthens brand identity, demands manufacturing precision that improves quality, and builds consumer trust that enhances loyalty.

The question for beauty and personal care brands is no longer whether to adopt sustainable plastic packaging, but how to execute it with the sophistication necessary to maintain competitive advantages across aesthetics, functionality, and economics. The brands succeeding in this transition recognize that sustainability without compromise requires patience, expertise, collaboration, and systems thinking — but delivers enduring value that superficial eco-claims never achieve.

FAQs

Is sustainable plastic packaging always more expensive than conventional packaging?

Not necessarily. While initial tooling and material costs may be higher, sustainable packaging often reduces long-term expenses through material efficiency, lightweighting, and optimized designs. Brands that integrate sustainability from the design phase — rather than retrofitting it later — typically see better cost outcomes. The key is viewing sustainability as a system optimization rather than a material premium. PCR pricing can fluctuate, but long-term contracts and economies of scale are closing the cost gap with virgin plastics.

What PCR percentage should I aim for in my packaging?

There’s no universal “right” PCR percentage — it depends on your product requirements, brand positioning, and production scale. Higher PCR content doesn’t automatically mean better sustainability if it compromises structural integrity or increases rejection rates. Most successful projects optimize PCR between 25-50% for cosmetic packaging, balancing performance with environmental benefits. Start with what your design can reliably support, then increase gradually as material quality and processing expertise improve.

Will PCR plastic make my packaging look cheap or inconsistent?

Not if designed properly. Color inconsistency is the most common challenge with PCR plastics due to varied post-consumer sources. However, this can be managed through controlled sourcing, strategic color selection (darker colors mask variability better), specialized color dispersion technology, and appropriate surface treatments. Premium perception comes from structural design, tactile quality, and finish precision — not from the plastic being virgin material.

What's the difference between biodegradable, compostable, and recyclable plastics?

These terms describe different end-of-life pathways. Recyclable plastics can be reprocessed into new products through existing infrastructure (like PET and HDPE). Compostable plastics break down in industrial composting facilities under specific conditions. Biodegradable means materials decompose naturally, but without a timeline or facility requirements — making this term less meaningful. For beauty packaging, recyclable mono-material designs typically offer the most practical sustainability benefits because they work with existing waste management systems.

How do I know if my sustainable packaging is compatible with my cosmetic formula?

Compatibility testing is essential, especially when using PCR or alternative materials. Standard tests include overall migration testing (measuring substance transfer from packaging to product), specific migration testing (identifying particular chemicals like phthalates or heavy metals), stability testing under accelerated aging conditions, and chemical compatibility assessments. PCR materials may have different permeability characteristics than virgin plastics, so testing with your actual formula is critical before full-scale production.

How do I prepare for upcoming EPR (Extended Producer Responsibility) regulations?

EPR regulations are expanding globally, requiring brands to take financial responsibility for their packaging’s end-of-life. To prepare: design packaging that minimizes material usage and maximizes recyclability now, choose mono-material designs that work with existing recycling infrastructure, document your packaging materials and weights for accurate reporting, consider refillable systems to reduce total packaging tonnage, and work with manufacturers who understand regional EPR requirements. “Future-proofing” your packaging by exceeding current requirements positions you ahead of regulatory changes rather than scrambling when deadlines arrive.