Quote

Custom Packaging Process

Our capabilities span custom design, rapid prototyping, mass production, and global logistics—with complete project management from consultation to delivery. We transform packaging visions into reality with precision and efficiency. Whether you’re launching your first product or scaling globally, our collaborative process ensures risk-free development, reliable quality, and on-time delivery that protects your products and elevates your brand presence.

• Zero Guesswork, Complete Transparency

Know exactly where your project stands at every moment. Our crystal-clear five-step process eliminates surprises, hidden costs, and communication gaps. You’ll never wonder “what’s next?” or “when will this be done?” Real-time updates keep you informed and in control throughout production.

• One Expert, Your Entire Journey

Forget endless email chains and departmental transfers. Your dedicated project manager becomes your packaging expert from first call to final delivery—someone who knows your brand, anticipates your needs, and answers in minutes, not days. This single point of contact streamlines decisions and accelerates your timeline.

• Quality Guaranteed or We Make It Right

Every bottle or jar undergoes rigorous inspection at multiple production stages. If anything falls short of our exacting standards—or yours—we don’t just apologize. We remake it. No arguments, no fine print, no exceptions. Your satisfaction and brand reputation matter more than our production schedule.

• Touch It Before You Buy It

Why gamble on mass production? Test real prototypes with your actual products before we manufacture a single unit. Feel the quality, verify the fit, and make changes risk-free—ensuring perfection before investment. Physical samples reveal what digital mockups simply cannot show you accurately.

Will it be complicated to work with you for the first time?

Not at all. We’ve designed our custom packaging process to be straightforward and stress-free, especially for first-time clients. From your initial inquiry to final delivery, you’ll have a dedicated project manager guiding you through each step. Our five-stage process is transparent, collaborative, and built around your timeline and budget. Most clients are surprised by how smooth the experience is—we handle the complexity so you don’t have to.

Here’s how we bring your custom packaging vision to life.

Our Custom Packaging Process

Step 1 · Requirements Discovery

This is where every successful packaging project begins. We take time to understand your product, brand positioning, and commercial goals, ensuring all recommendations are accurate, feasible, and aligned from the start.

Timeline: about 6 business days

What We Do

• Arrange consultation calls or in-person meetings based on your preference

• Evaluate product dimensions, weight, fragility, and protection requirements

• Recommend suitable packaging structures and material options

• Provide guidance on budget ranges and minimum order quantities

• Share relevant case examples or samples to inspire packaging direction

• Assess special considerations such as sustainability targets and regulatory compliance

What We Need From You

• Product dimensions, weight, and fragility level

• Estimated order quantities and target delivery timeline

• Brand guidelines, including colors, fonts, and overall visual style

• Budget range to help us propose the most suitable solution

• Any special requirements such as eco-friendly materials, temperature resistance, or anti-tamper features

What You Get

• Establish a clearly defined project direction with aligned expectations from the outset

• Receive accurate cost and timeline estimates based on early feasibility evaluation

• Build a solid foundation for efficient design development in subsequent stages

Step 2 · Custom Design Development

With clear requirements in place, our design team transforms ideas into functional, brand-driven packaging solutions that balance aesthetics, protection, and manufacturability.

Timeline: about 10 business days

What We Do

• Develop initial packaging concepts tailored to your specifications

• Create 3D mockups and visual renderings for realistic evaluation

• Ensure structural strength, usability, and product compatibility

• Refine designs based on feedback to achieve final approval

• Confirm compliance with relevant industry standards

• Optimize designs for cost efficiency without compromising quality

What We Need From You

• Clear and timely feedback on proposed design concepts

• High-resolution brand assets, including logos and graphic elements

• Preferences for finishes, textures, or special features

• Final design confirmation to proceed to sampling

• Any required compliance documentation or certifications

What You Get

• Obtain brand-consistent packaging designs that enhance shelf presence and brand recognition

• Reduce development risk by identifying potential issues prior to physical sampling

• Accelerate approval cycles through clear visualization and structured decision-making

Step 3 · Prototyping & Sample Creation

Before mass production, physical samples allow you to evaluate structure, materials, and finish quality with confidence.

Timeline: about 50-60 business days

What We Do

• Produce physical samples using production-grade materials

• Test packaging for durability, functionality, and fit

• Deliver samples for hands-on review and testing

• Adjust structure or appearance based on feedback

• Finalize specifications for mass production

• Provide technical drawings and material specifications

What We Need From You

• Detailed feedback on sample appearance and performance

• Results from any internal product fit or usage tests

• Approval to proceed with mass production

• Confirmation of final adjustments

What You Get

• Gain physical validation of packaging before committing to full production

• Minimize the risk of costly errors during mass manufacturing

Step 4 · Mass Production

Once samples are approved, we move into full-scale production under strict quality control systems to ensure consistency across every unit.

Timeline: about 35-40 business days

What We Do

• Source qualified materials according to approved specifications

• Manage the full production process with experienced supervision

• Conduct multi-stage quality inspections throughout manufacturing

• Provide progress updates during production

• Ensure color consistency and specification accuracy

• Maintain complete production and quality documentation

What We Need From You

• Final purchase order with confirmed quantities

• Payment according to agreed terms

• Confirmation of delivery schedule expectations

• Notification of any last-minute adjustments within allowable limits

What You Get

• Receive stable and scalable production output that supports long-term brand growth

• Benefit from reliable manufacturing timelines with reduced uncertainty

Step 5 · Quality Inspection & Shipping

Before shipment, every order undergoes final inspection. We then coordinate secure and efficient delivery to your destination.

Timeline: about 50 business days

What We Do

• Perform final quality inspection on finished products

• Arrange protective packing and palletization for transport

• Coordinate shipping with trusted logistics partners

• Provide shipment tracking information

• Prepare export and customs documentation for international orders

• Support delivery confirmation and post-delivery follow-up

What We Need From You

• Complete shipping address and delivery requirements

• Preferred delivery window and receiving details

• Customs information for international shipments

• Confirmation of receipt and feedback after delivery

What You Get

• Receive market-ready packaging that meets quality standards and protects brand reputation

• Experience a smooth and well-coordinated delivery process with minimal operational effort

Fast-Track Timeline: Speed That Matches Your Launch

Packaging Solutions We Customize

We create custom packaging across all major beauty and personal care categories. From concept to production, we tailor every component to your product specifications and brand vision.

Premium Bottles & Advanced Dispensing Systems

• Airless pump bottles for serums and treatments

• Glass dropper bottles for oils and concentrates

• Lotion and spray bottles for personal care

• Foundation and makeup remover bottles

• Toner and essence bottles

• Foam and roll-on applicator bottlesLuxury Jars & Skincare Treatment Containers

• Cream jars for moisturizers and masks

• Cosmetic jars in glass, acrylic, or sustainable materials

• Body butter containers

• Glass jars with bamboo lids for eco-luxury presentationCosmetic Tubes & Precision Application Solutions

• Cosmetic tubes for creams and gels

• Mascara tubes with custom wands

• Lip gloss and lip balm tubes

• Essential oil roller bottles

• Stick containers for deodorants and balmsSpecialty Packaging & Concentrated Treatment Containers

• Compacts for pressed powders

• Ampoules for concentrated treatments

• Syringes for precise serum application

• Sunscreen bottles with dispensing mechanisms

• Amber glass bottles for light-sensitive formulasEco-Friendly Materials & Sustainable Packaging Solutions

• Recyclable packaging across all categories

• Refillable bottle systems

• Biodegradable containers

• Bamboo bottles and closures

• Paper box alternatives to plasticCoordinated Product Sets & Complete Packaging Collections

• Coordinated skincare sets

• Personal care product lines

• Travel kits and mini containers

• Gift sets with custom inserts

• Packaging collections with unified brandingCustom Closures, Precision Pumps & Dispensing Accessories

• Custom caps and closures

• Pumps and sprayers in various output sizes

• Inner seals and tamper-evident features

• Custom applicators and brushes

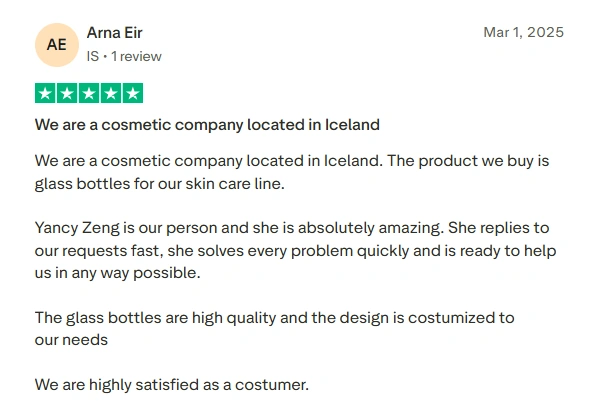

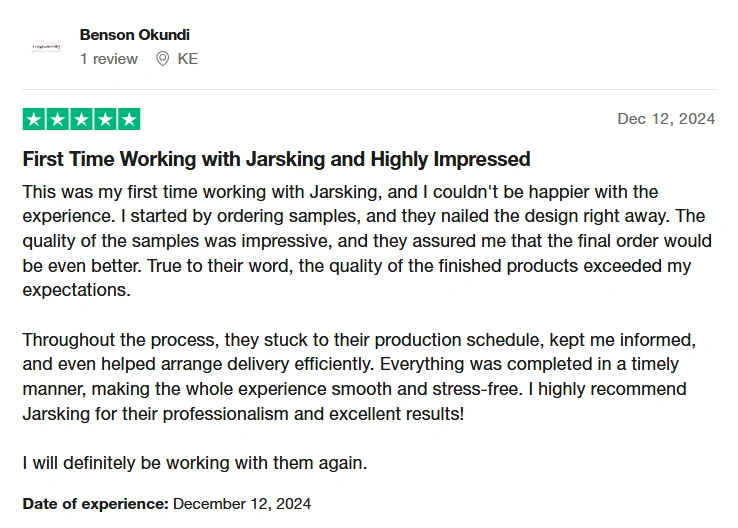

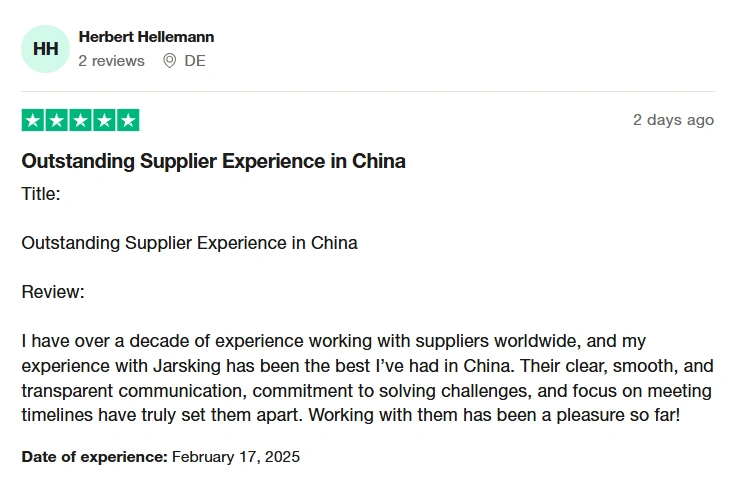

What Our Customers Say

Our clients unanimously agree that working with Othilapak on custom packaging projects is incredibly simple and convenient, especially for first-time clients. Our packaging enhances the unboxing experience, increases product appeal on store shelves, and we are able to create a cohesive and coordinated packaging series across multiple product lines, all while maintaining exceptional quality throughout the entire process.

Frequently Asked Questions

Q: What file formats do you need for custom design work?

A: We accept AI, PDF, EPS, PSD, and high-resolution PNG or JPG files in CMYK color mode with outlined fonts. Don’t have design files ready? Our in-house design team creates everything from scratch based on your brand guidelines and vision.

Q: Can you design packaging that accommodates multiple product sizes within one collection?

A: Yes, we specialize in coordinated packaging programs that maintain brand consistency across multiple SKUs and product formats. Our design team creates modular systems with unified visual language while tailoring dimensions and structural features to each product’s specific requirements.

Q: Is your custom packaging process suitable for first-time buyers without prior manufacturing experience?

A: Yes, our process is specifically designed to accommodate clients with varying levels of experience. Each project is assigned a dedicated project manager who provides expert guidance through requirements discovery, design approval, prototyping, and production—eliminating complexity and ensuring informed decision-making at every milestone.

Q: Can you accommodate ongoing packaging supply programs with scheduled releases?

A: Yes, we offer warehousing and inventory management programs with scheduled release schedules. This ensures continuous packaging availability without requiring you to store large quantities or tie up capital in bulk inventory, with releases coordinated according to your production and fulfillment schedules.

Q: How do I determine which packaging material is right for my product?

A: Material selection depends on three primary factors: product characteristics (weight, fragility, chemical compatibility), brand positioning (luxury versus accessible), and sustainability objectives. During consultation, we assess your product requirements and recommend optimal substrates—from rigid board for premium cosmetics to biodegradable options for eco-conscious brands.

Q: Do you support packaging design for specific retail channels (e-commerce, luxury retail, mass market)?

A: Yes, we tailor packaging design to distribution channel requirements. E-commerce packaging emphasizes protective structure and unboxing experience. Luxury retail demands premium materials and sophisticated finishing. Mass market focuses on cost efficiency and shelf impact. Channel-specific expertise ensures your packaging performs optimally in its intended environment.

Start Your Custom Packaging Project Today

Share a few details about your packaging needs and receive a personalized quote within 24 hours—no obligation, no pressure. Whether you’re launching your first product or scaling an established line, our team is ready to guide you through every step of the custom packaging process.