1. Introduction: When Vision Meets Reality

You’ve perfected the formula, built a brand that inspires, and crafted a marketing plan ready to make waves. Everything feels set—until you hit a three-letter barrier: MOQ, or Minimum Order Quantity.

For many indie beauty founders, that number—10,000, 20,000, even 50,000 units—can feel like a locked gate guarding entry into the cosmetics world. It’s not creativity, vision, or product quality that stands in the way; it’s the logistics of packaging.

At Othilapak, we speak with passionate entrepreneurs every day who face this same challenge. We understand what it’s like to be launch-ready but stalled by manufacturing minimums. That’s why we’ve created this guide—to demystify MOQs, explain why they exist, and show how you can navigate them strategically to bring your vision to life.

2. Why Minimum Order Quantities Exist

Before you can navigate MOQs effectively, it’s essential to understand why they exist. Minimum Order Quantities aren’t arbitrary numbers—they are foundational to how efficiency, quality, and pricing are maintained in the packaging manufacturing process .

Machine Setup and Tooling Realities

Every production run—whether for bottles, jars, or tubes—begins with a rigorous setup phase. Large industrial machines must be cleaned, loaded with raw material, and calibrated to achieve precise thickness, weight, and color. Skilled technicians oversee these steps, which involve labor, downtime, and energy use.

Here’s the catch: setup costs remain the same whether you produce 1,000 or 100,000 pieces. These fixed costs only become economical when spread over a larger volume. That’s why higher-quantity runs bring a lower price per unit, while smaller batches inevitably carry a higher cost .

Raw Material Sourcing and Supply Chain Economics

Packaging manufacturers also navigate supplier-side MOQs. Resins such as PET, PP, or post-consumer recycled plastics are sold by the ton to ensure consistent quality, and colorants or coatings are produced in fixed minimum volumes. When a packaging maker purchases these materials in bulk, costs remain manageable; ordering in smaller amounts disrupts the supply chain and inflates the per-unit price .

In short, packaging suppliers establish their own minimums based on the economies of raw-material procurement—creating a cascading MOQ effect that brands must account for when planning orders.

Production Efficiency and Color Consistency

Modern packaging lines run most efficiently when they operate continuously. Each pause—to switch molds, change colors, or fine-tune a pigment—creates material waste and lost time. For example, achieving a custom shade may consume several kilograms of pigment before color stability is reached. Manufacturers therefore require a minimum batch size to justify this waste and ensure the process remains cost-efficient .

The Economics of Scale in Practice

Ultimately, high MOQs reflect the basic economics of scale: mass production lowers per-unit costs, reduces machine wear and tear per item, and maintains repeatable quality standards. In cosmetic packaging, typical MOQs range between 5,000 and 20,000 units depending on material and customization .

3. The Startup’s Dilemma

High minimum order quantities (MOQs) might be perfectly rational from a manufacturer’s perspective, but for emerging beauty and personal care brands, they can feel like an insurmountable barrier. After investing months of effort and significant capital into formulation, product testing, and marketing, founders are often confronted with a packaging requirement that threatens to derail their entire launch strategy.

Capital Pressure: One Packaging Run Can Drain the Budget

Large upfront orders—often starting at 10,000 units per SKU—place immense pressure on early-stage brands with limited capital. Many indie beauty businesses launch with budgets under $50,000, and a single packaging order can consume more than half of their available funds. This financial burden doesn’t just affect packaging; it forces founders to make trade-offs, often cutting back on critical activities like marketing campaigns, e-commerce development, regulatory compliance, and influencer partnerships. The result is a weakened launch plan where beautiful packaging exists—but there’s no money left to actually reach the market effectively.

Storage and Logistics: Hidden Costs That Compound Over Time

Once packaging is produced, the challenges don’t end. Managing thousands of units requires dedicated warehouse space, inventory tracking systems, shipping coordination, and often insurance coverage. For a lean startup, these logistics expenses can snowball quickly. What seemed like a good deal on a bulk order can turn into ongoing monthly costs that eat away at slim profit margins. In some cases, founders are forced to rent off-site storage or pay 3PL (third-party logistics) providers—expenses that weren’t fully accounted for during the planning stage.

Limited Flexibility: Innovation Stifled by High Commitments

Early-stage beauty brands rely on agility. Rapid iteration after launch—tweaking bottle shapes, adjusting label designs, shifting colors, or adding premium finishes—is often what helps refine a product-market fit. However, when MOQs lock brands into thousands of identical components, the ability to pivot or update the design evaporates. This can result in sitting on packaging that no longer aligns with the brand’s direction, forcing businesses to either waste stock or delay innovation. For a category as design-sensitive as beauty, being trapped in the wrong look can cost valuable momentum.

Opportunity Delay: When Lead Times Slow Growth

High MOQs also typically come with longer lead times. Since suppliers prioritize large-volume contracts, small and mid-sized brands are often placed at the back of the production schedule. Lead times of 8 to 16 weeks are not uncommon, delaying launches and cash flow. These delays can have cascading effects—missing seasonal trends, losing retail shelf opportunities, or falling behind competitors who are already in the market. For brands built on speed, social engagement, and trend alignment, every month of delay translates directly into lost opportunity.

4. How Othilapak Redefines the MOQ Equation

High MOQs have long been a major obstacle for young beauty and personal care brands. While large manufacturers benefit from economies of scale, smaller brands are often forced to overextend their budgets, store excessive inventory, or delay launch plans.

Othilapak was created to change this dynamic. Our approach does not ignore MOQs; instead, we redesign how they function to make professional packaging more accessible, flexible, and sustainable for growing brands.

A Library of 30,000+ Stock Molds

Traditional packaging development typically begins with tooling — a process that requires engineering new molds from scratch. This step is expensive, time-consuming, and often drives MOQs upward. Othilapak eliminates this barrier by giving clients direct access to a mold library that already contains more than 30,000 stock options.

This library includes a full spectrum of packaging forms such as bottles, jars, tubes, droppers, pumps, and closures. Because these molds are engineered and owned by us, clients are not required to pay tooling or development fees. This structure removes one of the most significant financial triggers for high MOQs.

By leveraging existing molds, brands can select packaging structures that are already production-ready. This allows startups to move forward without heavy upfront investments, enabling them to reserve their budget for marketing, distribution, or product development rather than infrastructure costs.

Shared Production and Smarter MOQ Structures

Othilapak uses a production model that encourages shared manufacturing. When multiple brands select the same mold type—such as a standard PET bottle—we can schedule their production orders within the same manufacturing cycle.

This shared production model benefits everyone involved. It allows us to maintain factory efficiency and consistent quality standards, while each brand can place a smaller order quantity than would typically be required for a custom mold. Instead of forcing one brand to meet a very high minimum, the total MOQ is distributed across several participating clients.

The outcome is a more balanced system: smaller brands can access professional-grade packaging at manageable quantities, while the manufacturing process remains efficient and cost-effective.

Rapid Turnaround That Matches the Pace of Modern Markets

The beauty and personal care sector moves quickly. Trends spread rapidly on platforms like TikTok, and DTC brands rely on fast product cycles to stay relevant. Traditional custom mold development often takes months, slowing momentum and increasing the risk of missing market opportunities.

By using Othilapak’s stock molds, brands bypass this lengthy development phase entirely. Once the design, material, and finishing details are confirmed, production can begin immediately. Many clients receive their packaging within weeks instead of waiting several months.

This accelerated timeline allows startups to launch products faster, react quickly to consumer feedback, and restock efficiently. Speed to market is often the difference between leading a trend and missing it altogether.

Creative Customization Without Compromise

One common misconception is that lower MOQs mean limited design possibilities. At Othilapak, this is not the case. We have developed a comprehensive customization system that allows brands to create unique, premium packaging using stock molds as the foundation.

We offer a wide range of finishing and decoration techniques. Clients can select custom colors using masterbatch or specialized coatings to align the packaging with their brand identity. Silk screen printing enables logos, ingredient details, or storytelling elements to be applied directly to the surface. Hot foil stamping creates a premium metallic effect that enhances brand presence.

In addition, a variety of surface treatments are available, including matte, glossy, and soft-touch finishes, which give the packaging a distinct tactile quality. Optional effects such as frosting, gradient sprays, and embossing can add further depth and visual impact. These techniques transform a standard mold into a highly personalized packaging solution without forcing brands to commit to massive volumes.

Sustainable Options for Responsible Growth

Smaller batch production is naturally aligned with sustainable practices. By ordering only what is needed, brands avoid overproduction, reduce excess inventory, and minimize material waste. This not only improves cost management but also strengthens a brand’s environmental positioning.

Othilapak provides packaging options made from recyclable and post-consumer recycled (PCR) materials. Startups can choose eco-friendly solutions that align with their values and communicate those values clearly to their customers. This approach supports both environmental responsibility and transparent brand storytelling, helping young companies build trust with increasingly sustainability-conscious consumers.

5. The Strategic Value of Flexible MOQ

Faster and Smarter Product Launches

Lower MOQ empowers brands to move quickly and test intelligently. Instead of committing to a massive production run before knowing how customers will respond, brands can release smaller batches to the market, gather feedback, and make targeted refinements. This agility turns launches into learning opportunities, allowing founders to adjust design, packaging details, or positioning based on real market reactions rather than assumptions.

Stronger Cash Flow Control

When you are not required to purchase tens of thousands of units upfront, you preserve critical working capital. This gives startups the freedom to invest in marketing, digital campaigns, influencer outreach, regulatory preparation, or channel expansion—areas that directly drive growth. Flexible MOQ transforms packaging from a heavy upfront expense into a manageable, scalable investment.

Reduced Waste and Lower Risk

A smaller initial order also means fewer unused or obsolete components if your brand evolves. Rebranding, adjusting formulas, or shifting positioning is much easier when you aren’t locked into thousands of outdated units. This reduces environmental waste, prevents unnecessary storage costs, and protects your bottom line from sudden strategic changes.

Data-Driven Growth and Confident Scaling

With flexible MOQs, inventory no longer dictates your business decisions. Instead, data drives growth. Brands can begin with a pilot run, monitor real sales results and consumer feedback, and then scale production based on proven demand. This approach creates a sustainable, responsive growth cycle—one that aligns manufacturing with market reality rather than forecasts alone.

This strategy is at the heart of Othilapak’s model. Many of our clients start small, analyze their market performance, and scale up with confidence, turning what was once a packaging constraint into a powerful growth tool.

6. dome BEAUTY: Small-Batch Innovation with Cosmogen

dome BEAUTY is a clean cosmetics brand that wanted safe, high-quality packaging for its new eye brush collection but didn’t have the large budget required for traditional high-volume production. Instead of ordering tens of thousands of units, the brand looked for a packaging partner that could support a smaller, more flexible launch.

They partnered with Cosmogen, a supplier known for working with emerging beauty brands. Cosmogen produced a charcoal-infused eyeshadow brush with a small initial order of 5,000 units, allowing dome BEAUTY to launch without taking on unnecessary financial risk.

Because of the low MOQ, dome BEAUTY could use more of its budget for marketing, sampling, and building brand awareness instead of tying up cash in large packaging orders. At the same time, the brand was able to customize the brush design, including the special bristles and elegant finishes, so the product still reflected its clean, modern identity.

This approach gave dome BEAUTY the freedom to launch confidently, test the market, and grow at a sustainable pace, proving that small production runs can still deliver professional-grade results.

7. Practical Guidance for Founders

Launching a new beauty or personal care product is as much a strategic supply chain exercise as it is a creative process. Packaging choices and MOQ negotiations can either give your brand room to grow—or lock you into costly commitments too early. The following principles can help founders make smarter, more flexible decisions from the start.

Define Your True Launch Volume

Many founders overestimate their initial order size, basing MOQ targets on long-term aspirations rather than immediate reality. A more effective approach is to calculate a realistic sales projection—often equivalent to a three-month supply—rather than committing to an entire year’s worth of packaging. This not only lowers your upfront costs but also reduces the pressure of storing and managing excess inventory. By grounding your order in actual launch needs, you keep your cash flow fluid and your operations lean.

Prioritize Stock Molds Whenever Possible

Custom molds can elevate a product’s identity, but they come with high costs, long lead times, and rigid MOQs. Stock molds offer a smarter entry point. They provide the same professional quality and precision manufacturing standards while requiring a much lower initial commitment. Instead of reinventing the mold, focus your investment on finishing techniques—such as coating, screen printing, embossing, or foil stamping—to make the packaging uniquely yours. This strategy allows your brand to look premium without overspending at launch.

Ask About Batch Sharing Opportunities

Many manufacturers are willing to combine multiple brands’ orders during production runs. This practice, known as batch sharing, can significantly lower the MOQ for each participating brand while maintaining production efficiency. It allows startups to access professional packaging at more manageable volumes. Othilapak is structured around this principle, enabling emerging brands to benefit from lower thresholds without compromising on quality or lead times.

Plan Custom Colors Strategically

Custom colors can powerfully reinforce brand identity, but they also add complexity to the production process. If a signature shade is essential to your launch, coordinate with your manufacturer to align production timelines with other compatible runs. If timing or budget is tight, start with transparent or neutral tones for your first production round and introduce your custom color in later batches. This approach keeps your launch flexible, fast, and financially controlled while leaving room to evolve visually over time.

Build Reorder Agility into Your Cash Flow

Many founders treat packaging as a single, fixed purchase, but successful brands view it as a dynamic cycle. Consumer response after launch will dictate how quickly your product needs to be restocked. By setting aside funds for quick reorder opportunities, you ensure that momentum is not lost just as your market presence begins to grow. Agility in reordering allows you to scale confidently, respond to demand spikes, and avoid stockouts that can slow brand growth.

These practices allow startups to approach packaging not as a hurdle, but as a strategic tool. By starting smart, staying flexible, and aligning production with real demand, founders can protect their resources, preserve brand identity, and build sustainable growth from the very first run.

8. Time Planning for Mold Opening Products

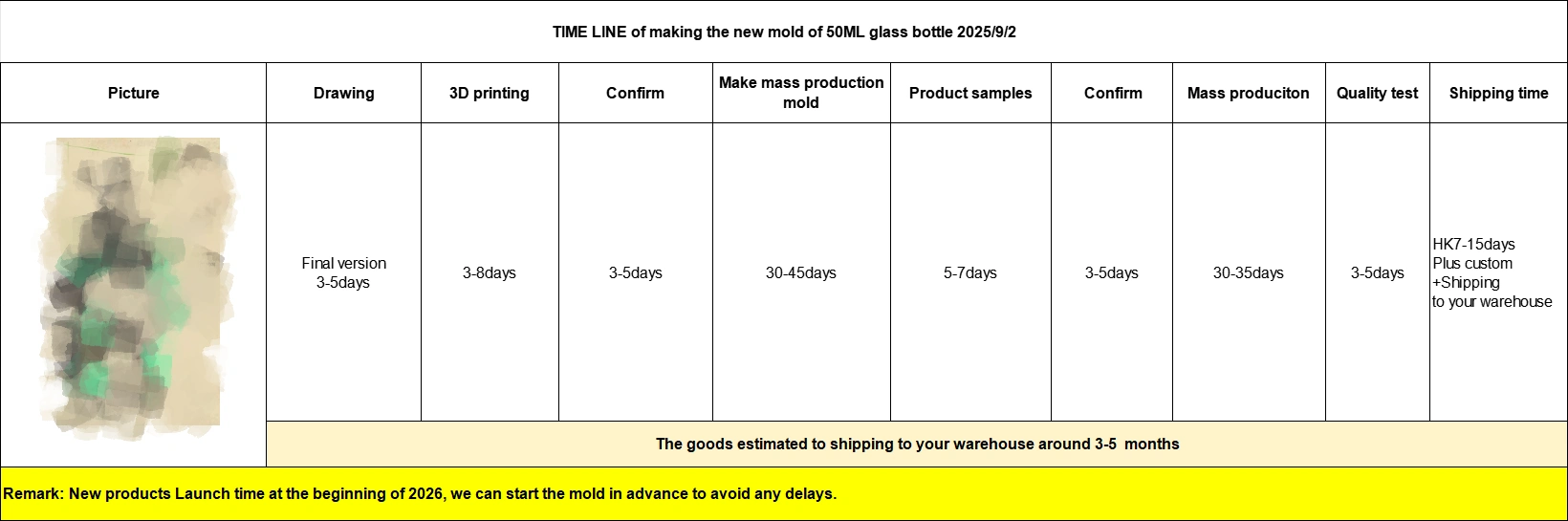

The following schedule is an approximate time reference provided by Othilapak, designed to help brands plan their product development and launch timelines more effectively.

From the moment a design is confirmed to the final shipment of finished goods, the development of a new mold typically takes about three to five months. This timeline includes essential steps such as design drawing, 3D prototype confirmation, mold fabrication, sample approval, mass production, quality inspection, and shipping.

Since each stage builds on the previous one, early and clear communication—along with fast feedback—helps ensure the entire process remains on schedule.

Why Timeline Planning Matters

For emerging and growing beauty brands, packaging isn’t just a technical step — it directly affects launch readiness, marketing campaigns, and inventory planning. Starting mold development well ahead of the planned launch date helps brands avoid production bottlenecks, secure stable lead times, and ensure that packaging aligns seamlessly with product filling, branding, and retail schedules.

For example, if your brand aims to launch a product at the beginning of the year, the mold development process should ideally begin several months earlier to allow sufficient time for each step and to accommodate any unforeseen adjustments.

Existing Molds vs. Opening New Molds

When planning packaging development, brands can choose between using existing molds or investing in a new mold. Each path has different implications for time, cost, and flexibility.

Using Existing Molds

Shorter Timeline: Since the mold already exists, production can begin immediately after material, finish, and decoration are confirmed. Lead time is often reduced to a few weeks, making it ideal for fast launches or pilot runs.

Lower Cost: No tooling investment is required, allowing startups to allocate more budget to marketing, formulation, or distribution.

Faster Market Entry: Ideal for brands testing new product concepts, entering new markets, or launching limited collections.

Slightly Lower Design Flexibility: The structure is fixed, but customization can be achieved through color, finish, printing, and decoration.

Opening a New Mold

Longer Timeline: Full development typically requires three to five months, including drawing, tooling, sampling, and production.

Higher Initial Investment: New mold fabrication involves tooling costs, though it can offer a strong long-term return for core or signature products.

Greater Design Freedom: A unique shape or structure can be fully customized to reflect the brand’s identity and positioning.

Strategic Fit for Hero Products: Best suited for long-term lines, flagship products, or collections where differentiation is critical.

9. Partnering Beyond the First Launch

At Othilapak, our relationship with indie beauty brands does not end when the first shipment leaves the factory. We see ourselves as a long-term partner and an extension of your product team, supporting your growth through every stage of development.

Design Support

Packaging is more than appearance—it shapes the entire product experience. Our team works closely with clients to refine finishes, improve usability, and ensure ergonomic comfort. This hands-on collaboration helps translate your creative vision into a tangible product that feels considered, functional, and premium.

Sample Programs

We understand the importance of making confident choices. Our structured sample programs give you the opportunity to touch, test, and evaluate real packaging components before committing to large-scale production. This step reduces risk and ensures the final product aligns perfectly with your expectations.

Material Innovation

Innovation should be accessible, not exclusive. From refillable systems and lightweight glass to compostable biopolymers, Othilapak keeps emerging packaging technologies within reach—offering practical MOQs that allow indie brands to explore forward-thinking materials without overextending their resources.

Scalable Supply Strategy

As your brand evolves, so do your production needs. We support a seamless transition from shared production runs to exclusive molds as order volumes grow. This structured scaling ensures consistency, avoids supply disruptions, and keeps your brand’s visual identity intact as demand increases.

With decades of experience, Othilapak brings together the precision of enterprise manufacturing and the attentiveness of a boutique partner, giving growing brands the confidence to scale without losing their creative edge.

10. Final Thoughts: Your MOQ Doesn’t Define Your Ambition

Every successful brand has faced the MOQ dilemma at some point. What sets them apart is not the absence of constraints, but their ability to transform those constraints into creative opportunity. By choosing partners who understand your scale, timing, and long-term vision, MOQ becomes a strategic tool rather than a barrier. It gives you the space to grow at your own pace without compromising design integrity or financial stability.

Your packaging should amplify your innovation, not restrict it. Othilapak stands beside you as more than a supplier—we are a partner committed to supporting your journey as your brand evolves, one flexible batch, one inspired launch, and one visionary idea at a time.