Modern society’s dependence on plastic packaging has been a double-edged sword. On one hand, plastics are lightweight, cheap, and have enabled global supply chains and modern conveniences. On the other, their non-renewable origins and resistance to natural degradation have made plastic waste one of the most pressing environmental crises of the 21st century. From food wrappers found in the world’s most remote oceans to microplastics entering our food chains, the need for new packaging solutions is urgent.

Enter bio-based packaging—materials made from renewable, biological resources. This innovative sector is catalyzing a revolution in how we think about materials, sustainability, and the intersection of ecological responsibility with consumerism. But what exactly is bio-based packaging? How is it made, what are its strengths and limitations, and is it the future of packaging? This article takes a deep dive into these questions, exploring the latest science, market trends, opportunities, and challenges.

1. The Need for Change

Environmental and Economic Impacts of Traditional Packaging

Traditional packaging materials, especially single-use plastics, constitute a majority of global packaging waste. Their resistance to degradation means they persist in the environment for centuries, contributing to overflowing landfills and the widespread pollution of terrestrial and aquatic ecosystems. Modern recycling rates are staggeringly low—only about 9% of plastic produced is recycled—while the rest is incinerated, dumped into landfills, or leaks into the environment.

The persistence of plastic waste comes with steep economic costs. Eventual cleanup, lost tourism revenue, and environmental remediation total billions of dollars each year. Moreover, the plastics sector’s reliance on fossil fuels accelerates resource depletion and greenhouse gas emissions.

Legislative Response and Consumer Demand

Governments and regulatory bodies worldwide are responding with bans and restrictions on single-use plastics, recyclable-content mandates, and eco-design requirements. The European Union’s Single-Use Plastics Directive stands as one of the most comprehensive legislative efforts, aiming to phase out problematic plastics and encourage sustainable alternatives.

On the consumer side, there is a marked shift toward eco-friendliness. Today’s shoppers are eco-savvy, often preferring brands with transparent sustainability practices. Companies are under greater pressure than ever to reduce their environmental impact—and packaging innovation stands as the most visible frontline in this transformation.

2. What Is Bio-Based Packaging?

Defining Bio-Based

Bio-based packaging is made from materials that are fully or partially derived from renewable biological sources, rather than fossil fuels. These biological resources include common agricultural crops like corn, potatoes, and sugarcane, as well as agricultural residues, trees, marine organisms such as seaweed and crustaceans, or even microorganisms cultivated in bioreactors.

Key attributes of bio-based packaging are:

- Renewability: Its raw materials come from resources that can be regrown or replenished on a human-relevant timescale.

- Potential for Biodegradability/Compostability: Many—but not all—bio-based materials can naturally break down into harmless substances either in composting settings or under certain environmental conditions.

- Lower Carbon Footprint: The overall carbon emissions from production to disposal are often less than those of fossil-derived plastics, especially when the packaging is composted or biodegraded rather than landfilled.

Bio-Based vs. Biodegradable

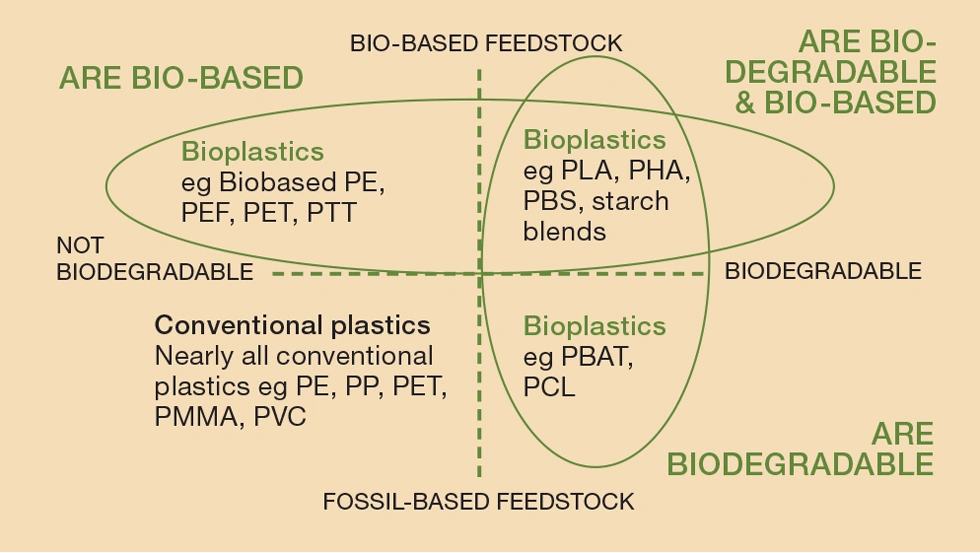

The terms “bio-based” and “biodegradable” describe two different characteristics:

- Bio-based tells you where the material comes from; it is all about origin.

- Biodegradable refers to what happens at the end of the material’s life—can it break down naturally, and under what conditions?

Not all bio-based plastics are biodegradable. For example, bio-PET is made from biological sources but has the same molecular structure as conventional PET plastic and does not biodegrade. Conversely, some fossil-derived plastics have been engineered to be biodegradable. The most environmentally advantageous packaging materials are those that are both bio-based and biodegradable, offering a renewable start and a gentle end-of-life path.

Types by End-of-Life

- Edible packaging: The material can be safely consumed by humans or animals, removing packaging waste entirely.

- Compostable packaging: Designed to decompose in composting environments, returning valuable nutrients to the soil.

- Recyclable packaging: Can be collected, reprocessed, and reused to make new products, reducing resource use and waste.

3. Historical Context

Before the creation of synthetic plastics, civilizations relied on natural, locally available materials for packaging—such as banana leaves, animal hides, and woven plant fibers. These materials were inherently renewable and biodegradable, integrating seamlessly into local ecosystems when discarded.

The late 19th and early 20th centuries saw the first forays into bio-based polymers with products like celluloid (made from cellulose and camphor) and cellophane (a transparent film made from regenerated cellulose). These materials marked humanity’s initial attempts at engineering packaging that retained the eco-friendly qualities of their natural predecessors while offering improved utility.

However, the post-World War II era triggered an explosion in petroleum-based plastic production. Plastics made from oil and gas—such as polyethylene, polypropylene, and PET—offered lower costs, easier mass production, and superior barrier properties. These benefits led to their near-total dominance in the packaging world.

Today, rising environmental awareness and advances in biotechnology are driving a renewed interest in bio-based packaging, seeking to combine the ecological advantage of bio-materials with the performance needs of a modern, globalized economy.

Key Bio-Based Packaging Materials

Starch-Based Polymers

Starch is harvested from plants like corn, potatoes, and cassava. It is easy to process and composts readily. In its pure form, starch is often brittle and sensitive to moisture. Manufacturers improve its properties by blending it with other biopolymers or using it to create foams.

Used for: Loose-fill packing peanuts, food trays, and compostable containers.

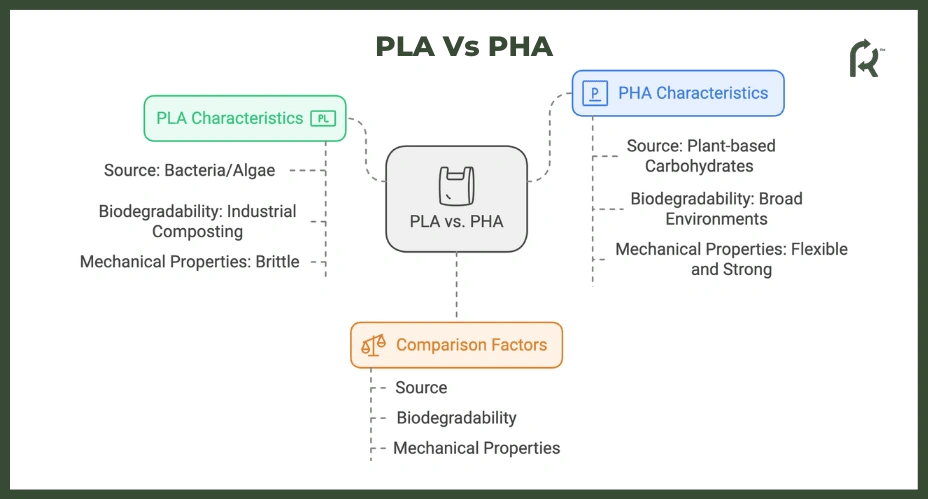

Polylactic Acid (PLA)

PLA is created by fermenting plant sugars—typically from corn or sugarcane—into lactic acid, which is then polymerized. PLA is transparent and rigid, closely mimicking PET plastic, though it requires industrial composting conditions to break down efficiently.

Used for: Drink and salad containers, disposable cups and cutlery, and as filament for 3D printing.

Polyhydroxyalkanoates (PHAs)

PHAs are produced by bacteria that consume plant oils or sugars, storing the polymer inside their cells. After harvest, PHAs can be processed into packaging that breaks down easily in environments ranging from home compost heaps to ocean water. This makes PHAs one of the most environmentally robust bioplastics.

Used for: Food packaging films, agricultural wraps, and specialty coatings.

Cellulose-Based Films

Cellulose, the main structural component of plants, can be extracted from wood pulp or agricultural byproducts. Cellulose can be chemically processed into flexible, transparent films such as cellophane. Modern cellulose packaging offers excellent breathability and can be engineered for good barrier properties.

Used for: Bakery bag windows, snack bar wrappers, and packaging for perishable foods.

Chitosan and Alginates

Chitosan is derived from the shells of shrimp, crabs, and other crustaceans, while alginates are extracted from seaweed. Both materials are valued for their antimicrobial actions and full compostability. They are often used in edible films or thin coatings to extend the shelf life of fresh produce.

Used for: Edible films and coatings for fruits and vegetables.

Novel Materials

Cutting-edge research is exploring mycelium (from fungus root systems), algae-derived polymers, and agricultural residues. These innovations have the potential to further reduce reliance on resources that compete with food crops and to create truly circular packaging systems—ones that begin and end as waste-free, renewable resources.

Bio-based packaging materials are diversifying rapidly, with new technological advances enabling even broader applications and a more sustainable, circular economy.

4. Innovations in Bio-Based Packaging

Active and Intelligent Features

Bio-based packaging isn’t just about replacing petroleum plastics with plant-derived materials—it’s also reshaping the functionality of packaging. Active packaging technologies use bio-based materials to extend food shelf life, preserve quality, and reduce waste. For instance, some films are infused with natural antimicrobials (like essential oils or plant extracts) or oxygen scavengers. These additions help slow spoilage by countering microbes or removing oxygen that accelerates degradation.

Intelligent (or smart) packaging takes things a step further by monitoring product condition. This can include built-in sensors, freshness indicators, or color-changing compounds that signal when a product is unsafe or nearing the end of its shelf life. These features are being integrated into bio-based substrates to create eco-friendly, data-rich packaging—bridging biotechnology with the digital age.

Nanomaterials and Biocomposites

Nanotechnology is driving some of the most exciting advances in bio-based packaging. When nanocellulose (ultrafine fibers derived from plants) or other nanoscale bio-fillers are added to bioplastics, they greatly increase durability, flexibility, and barrier performance without compromising compostability.

Biocomposites—which blend bioplastics with renewable fibers or clays—offer strong, lightweight packaging ideal for foods, electronics, and shipping. These innovations not only make bio-based plastics more functional but also reduce overall material usage and dependence on virgin resources.

Surface Modifications and Coatings

One challenge for early bio-based packaging was inferior resistance to water and gases, compared to petro-based plastics. Modern innovation solves this with surface modifications and specialty coatings. Techniques like multilayer construction, spray-coating, and chemical treatment can produce packaging that rivals traditional plastics in barrier performance.

This allows bio-based materials to safely contain moisture-sensitive goods, protect perishable foods, and survive rigorous supply chains—broadening the range of feasible, sustainable packaging solutions.

Bio-based packaging, therefore, is not just a “greener” swap—it’s a foundation for smarter, safer, and more resource-efficient systems in the future.

5. Environmental Performance and Waste Management

Life Cycle Impact

Studies using Life Cycle Assessment (LCA) demonstrate that bio-based packaging—when sourced and manufactured with sustainability in mind—can substantially reduce greenhouse gas emissions and environmental impacts compared to fossil-based plastics. Key factors improving the LCA profile of bio-based options include the use of renewable feedstocks (plants, agricultural waste), lower total energy requirements during production (if renewable energy is used), and end-of-life scenarios that prioritize composting or recycling over landfill disposal.

Importantly, the actual environmental benefit depends on the cultivation practices for biobased feedstocks, the energy mix of the manufacturing process, and the local waste management infrastructure. Well-managed systems can offer a path to net-zero or even carbon-negative packaging solutions.

Composting and Biodegradability

A major advantage of many bio-based packaging materials is their potential for composting. Compostable bio-packaging can reduce the volume of waste sent to landfills, returning organic matter to the soil and closing the nutrient loop. Materials like PHA are remarkable for their ability to biodegrade in home compost bins or even marine environments.

However, not all bioplastics behave the same. PLA, for example, requires industrial-scale composting facilities—high heat and humidity—to break down efficiently. If PLA enters traditional recycling streams or ends up in landfill, it may not fully degrade and can even contaminate recycling operations. Proper disposal, therefore, is essential to realize environmental gains.

Reducing Food Waste

Bio-based packaging doesn’t just address plastic pollution—it can also help cut down on food waste. Active and intelligent packaging (such as films with natural antimicrobials or indicators of spoilage) can extend the shelf life of fresh foods, limiting spoilage during transport, storage, and retail.

Edible and smart bio-based packaging innovations further enhance sustainability by offering new ways to preserve food quality and inform consumers, providing a double win for the environment: reduced plastic waste and less food wasted overall.

Bio-based packaging’s full environmental potential is unlocked when sustainable resource management, advanced product design, and robust waste processing infrastructures work hand in hand.

6. Market Adoption and Industrial Applications

Industry Leaders and Sectors

Bio-based packaging is no longer just a niche innovation—well-known brands and entire industry sectors are making substantial commitments to sustainable alternatives. For example:

- Coca-Cola’s PlantBottle initiative uses bio-PET (partially plant-derived PET) for soft drink packaging.

- Danone and IKEA have introduced bio-based or compostable packaging for select product lines, signaling a larger shift within multinational consumer goods.

- The food service and hospitality industry has quickly transitioned to compostable cutlery, cups, straws, and takeout containers, meeting consumer demand for convenience with a reduced ecological footprint.

Broader applications of bio-based packaging include:

- Grocery produce bags and retail trays, often replacing conventional poly bags and EPS foam

- Ready-meal and convenience food packaging, particularly for fresh and perishable goods

- Tubes, films, and rigid containers for personal care products (cosmetics, hygiene items)

- Electronics and appliance packaging, using molded bio-based foams and films for protection

Barriers to Widespread Adoption

Despite clear growth, several challenges impede more universal adoption:

- Cost: Manufacturing bio-based plastics is generally more expensive than producing traditional fossil-derived plastics, although increased scale and technological advances are gradually reducing this gap.

- Performance: Some bio-polymers have limitations with moisture and gas barriers, flexibility, or strength—posing difficulties for heavy, liquid, or long-shelf-life products.

- Composting and Recycling Infrastructure: Many regions lack widespread, high-capacity industrial composting facilities. Inconsistent product labeling and limited public awareness sometimes lead to improper disposal, which can cause cross-contamination in recycling streams or result in materials that do not biodegrade as intended, reducing the environmental benefits.

7. Regulatory and Certification Landscape

Global Policy Developments

Governments around the world are shaping the trajectory of bio-based packaging with evolving policies:

- European Union (EU): Leads globally with stringent mandates for composability, minimum recycled content, and labeling standards. The EU’s Single-Use Plastics Directive bans certain petro-based single-use items, accelerating the shift toward biodegradable and bio-based options.

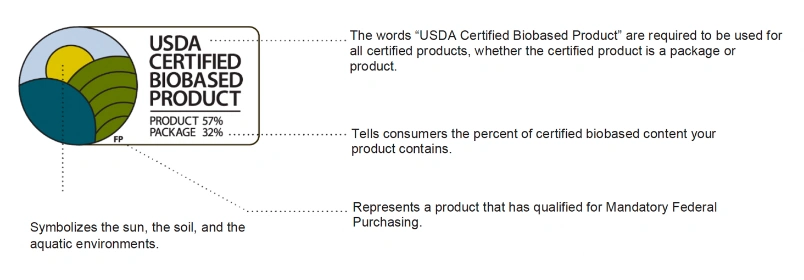

- United States: The federal USDA BioPreferred program labels products with certified biobased content, while individual states and cities enact their own laws restricting non-compostable packaging and incentivizing greener alternatives.

- Asia: Countries like China and India are expanding anti-plastic policies and setting targets for single-use plastics reduction, but the degree of support and acceptance for bio-based solutions varies regionally.

Certification Systems

Certification and clear labeling are essential for consumer trust and effective use of bio-based products. Key labels to watch for include:

- OK Compost and the Seedling logo: Indicate compliance with European standards for industrial compostability.

- USDA Certified Biobased: Found on qualifying products in the US, showing a verified percentage of renewable content.

- TÜV Austria: Offers certification for both home and industrial compostability, providing extra assurance for disposal flexibility.

- EN 13432: The European standard that defines requirements for packaging recoverable through composting and biodegradation.

Rigorous certification helps prevent greenwashing—the use of vague or misleading environmental claims without scientific substantiation—which can undermine consumer confidence and the environmental mission of sustainable packaging.

Clear policies and authentic certification are critical to guiding industry change, informing consumer choices, and ensuring that bio-based packaging delivers on its environmental promises.

8. Challenges and Limitations

Technical

Bio-based packaging materials, while innovative, sometimes struggle to meet the performance standards set by traditional plastics—especially in demanding conditions. Many bioplastics can be sensitive to moisture, heat, and oxygen, which affects their mechanical strength and barrier properties. For example, packaging used for liquids, frozen goods, or items requiring long shelf life may suffer from brittleness, deformation, or spoilage risks. To overcome these, scientists often engineer material blends or multilayer constructions, combining bio-based polymers with other materials for better performance. However, these complex structures can make recycling and composting more challenging, as layers might need to be separated or require specialized facilities.

Economic

Most industrial bioplastics still rely on agricultural crops like corn and sugarcane, raising concerns about competition with food production—a dilemma often called “food vs. plastic.” Researchers are developing ways to use non-food sources, such as agricultural residues, algae, or waste streams, but these are not yet widely scaled. Furthermore, global supply-chain volatility (due to climate, geopolitics, or economic shifts) and limited economies of scale can keep costs higher for bio-based packaging, making it harder to compete with mature, fossil-based plastics.

End-of-Life

The promise of sustainability hinges on proper disposal and waste processing. Many bio-based plastics are designed for industrial composting and will not degrade properly in backyard compost or if sent to landfill. Mixed waste collection—where compostable and recyclable items are combined—can contaminate recycling streams or result in bio-plastics not breaking down as intended. This mismatch undermines the environmental benefits and can even exacerbate waste management problems if not addressed with robust infrastructure and public awareness.

Greenwashing and Misconceptions

Marketing terms like “biodegradable” and “compostable” are sometimes used loosely, without independent verification or explanation of the precise conditions required for breakdown. This leads to greenwashing—where products appear greener than they really are. To maintain credibility and genuine environmental benefit, third-party certifications, standardized labeling, and consumer education are crucial. Only with clear standards and honest communication can the potential of bio-based packaging be realized and trusted by the public.

9. Future Directions

Synthetic Biology and New Feedstocks

The future of bio-based packaging is being shaped by breakthroughs in synthetic biology and resource innovation. Genetically engineered microbes are now able to produce custom-designed polymers from inexpensive, renewable feedstocks—including agricultural wastes—helping to bypass the “food vs. Plastic” debate that has dogged starch- and sugar-based options. These tailored processes can yield specialty bioplastics with improved performance, biodegradability, or unique properties designed for specific applications.

Researchers are also making strides in using non-traditional feedstocks:

- Algae: Fast-growing and able to grow in lands unsuitable for crops, algae can be cultivated to produce proteins and polysaccharides for bio-packaging.

- Fungi/Mycelium: Mycelium-based foams and fibers are strong, fully compostable, and can be grown with minimal inputs, offering sustainable alternatives to polystyrene and other synthetics.

- Carbon Capture Polymers: New technologies are emerging to convert captured CO₂ or industrial flue gases into building blocks for bioplastics, creating packaging that’s potentially climate-positive.

Circular Economy Potential

The next generation of bio-based packaging will be deeply rooted in the principles of the circular economy: eliminating waste, maximizing product lifespan, and keeping materials cycling through the system. This means designing packaging that is:

- Easily reusable (e.g., refillable pouches, returnable containers)

- Clearly and efficiently recyclable (with minimal contamination risk)

- Fully compostable, where environmental conditions and collection networks exist

True sustainability demands minimal environmental impact at every life stage—from sourcing and manufacturing to use, transportation, and end-of-life. Innovations are now focusing on making these closing loops easily navigable for consumers, businesses, and waste handlers alike.

Smart and Personalized Packaging

Pairing bio-based materials with digital technology is unlocking a new era of smart and personalized packaging. QR codes printed on eco-friendly films can offer consumers full product traceability, recycling guidance, or interactive brand experiences. Freshness sensors, color-change labels, and temperature indicators ensure food safety and quality while alerting users when items are nearing expiration—helping to further cut down on food waste.

As the Internet of Things (IoT) advances, packaging might soon be able to order its own refill, authenticate itself against counterfeiting, or provide seamless, end-of-life instructions tailored to the user’s location, all through smart, sustainable materials.

10. Conclusion and Call to Action

Bio-based packaging stands at the intersection of innovation, sustainability, and responsible consumerism. While it may not resolve every challenge in the modern supply chain or waste stream, it marks a decisive move toward packaging that is renewable, circular, and mindful of its impact on our planet. Bio-based solutions embody not just substitutions for conventional plastics, but genuine advancements—combining ecological intelligence with functional design and new technologies.

Real progress, however, depends on coordinated action at every level. Consumers play a critical role by choosing certified sustainable packaging, following disposal guidelines, and supporting brands that prioritize transparency and real environmental credentials. Businesses must invest in research, commit to honest product labeling and marketing, and collaborate across industries for better solutions and systems. Policymakers are needed to set ambitious, enforceable standards; to close infrastructure gaps for composting, recycling, and education; and to incentivize sustainable choices across markets.

The transformation in how we package, transport, and protect products is underway. As materials improve and supporting infrastructure grows, a less polluting, more resilient packaging landscape is within reach—one that not only reduces plastic waste but also builds a foundation for a genuinely sustainable future.