Quote

Custom Paper Box Packaging Manufacturer

The paper box packaging collection from Othilapak is crafted to meet the diverse needs of modern beauty and skincare brands, blending eco-friendly materials with advanced manufacturing and customizable design options. These boxes not only enhance product protection and presentation but also act as a powerful canvas for branding, supporting both minimal and luxury aesthetics to appeal to various market segments.

The flexibility in design—from unique shapes to advanced printing finishes—enables clients to align every detail with their brand story, ensuring both functional excellence and visual impact. Whether launching new product lines or elevating existing collections, Othilapak’s paper box packaging delivers superior quality, efficient logistics, and responsive expert support, making it the trusted partner for brands aiming to inspire and captivate through packaging.

Industries We Serve

Create Your Paper Packaging

Two-Piece Box

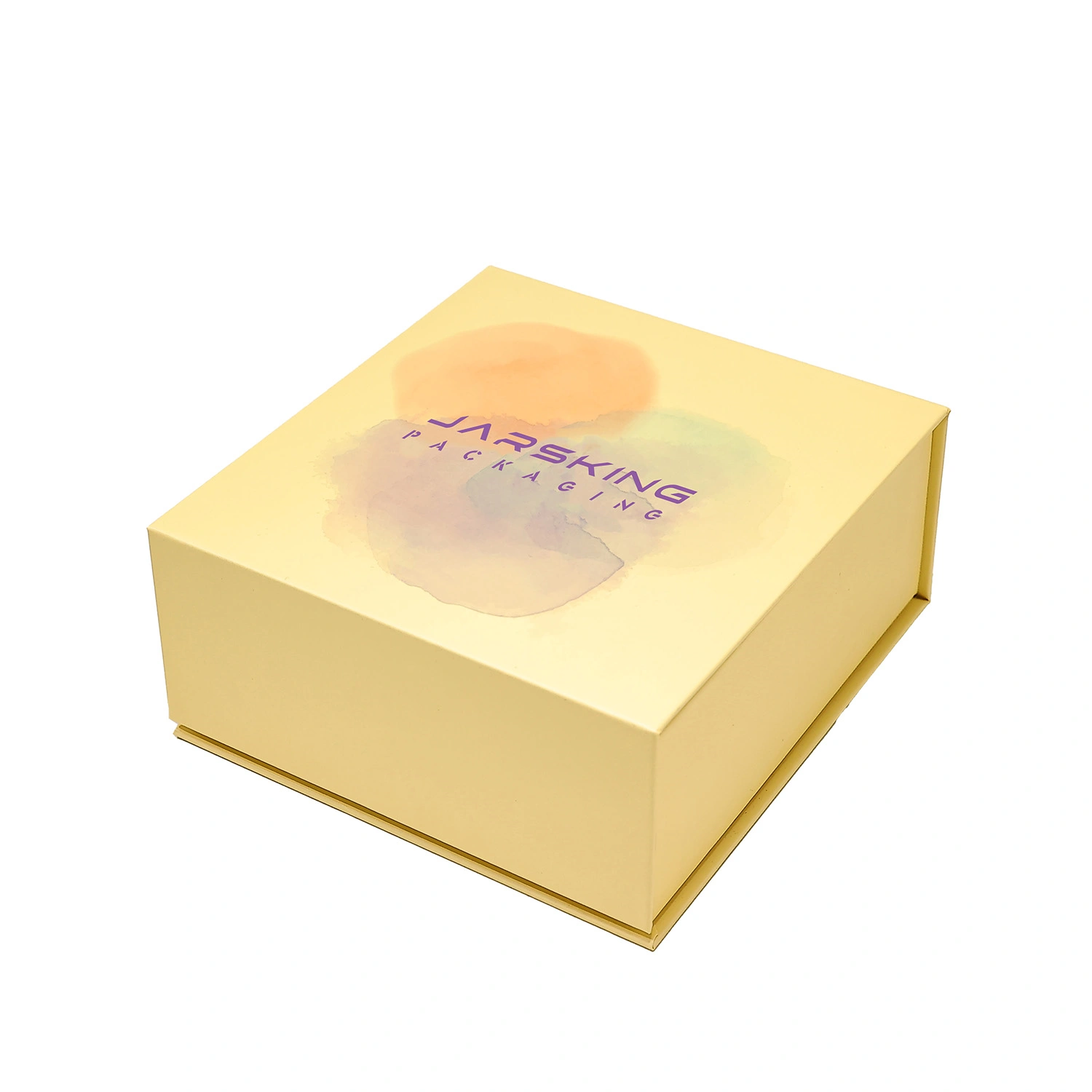

Magnetic Flap Box

Book-Style Box

Gift Box

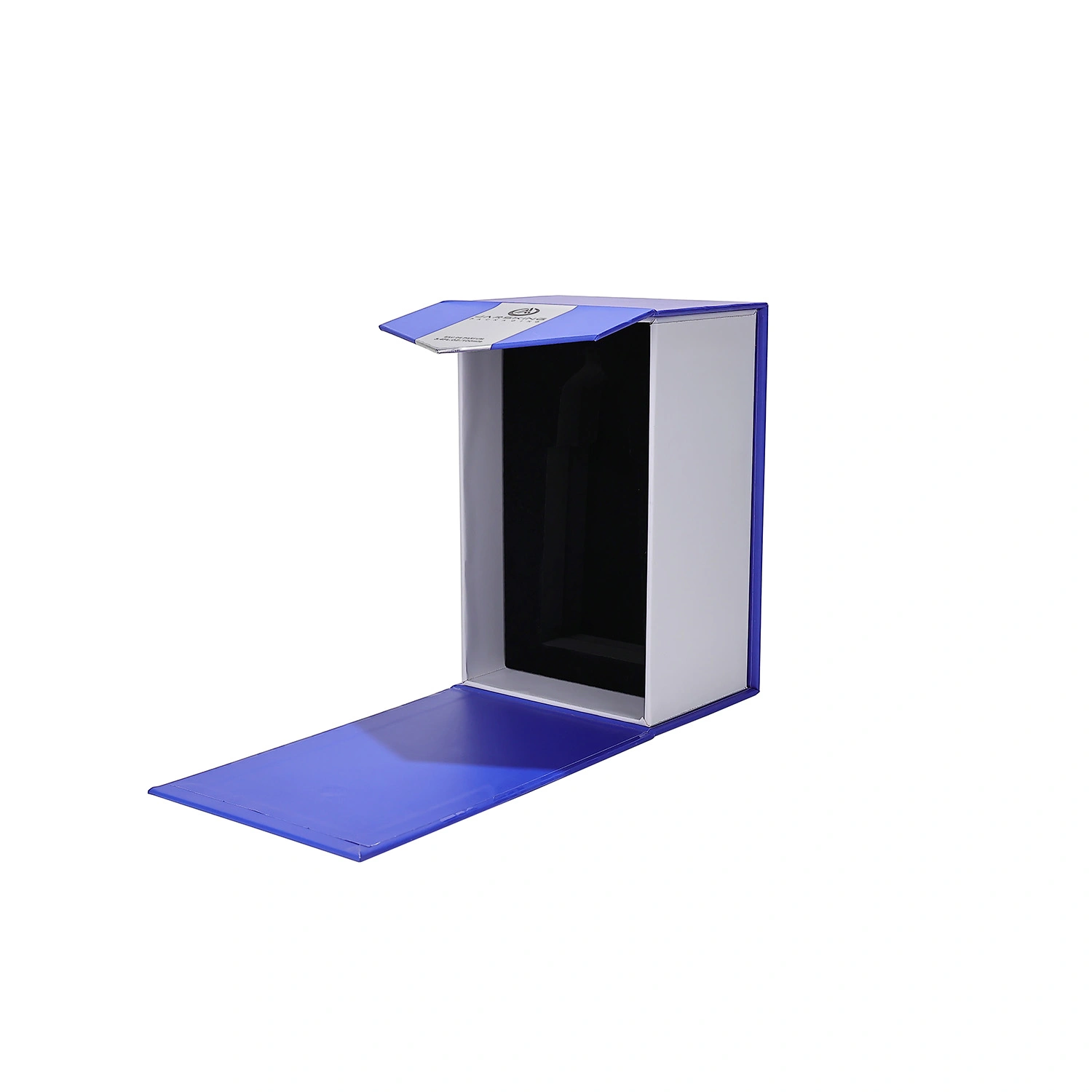

Double-Door Box

Cylinder Box

Carry Handle Box

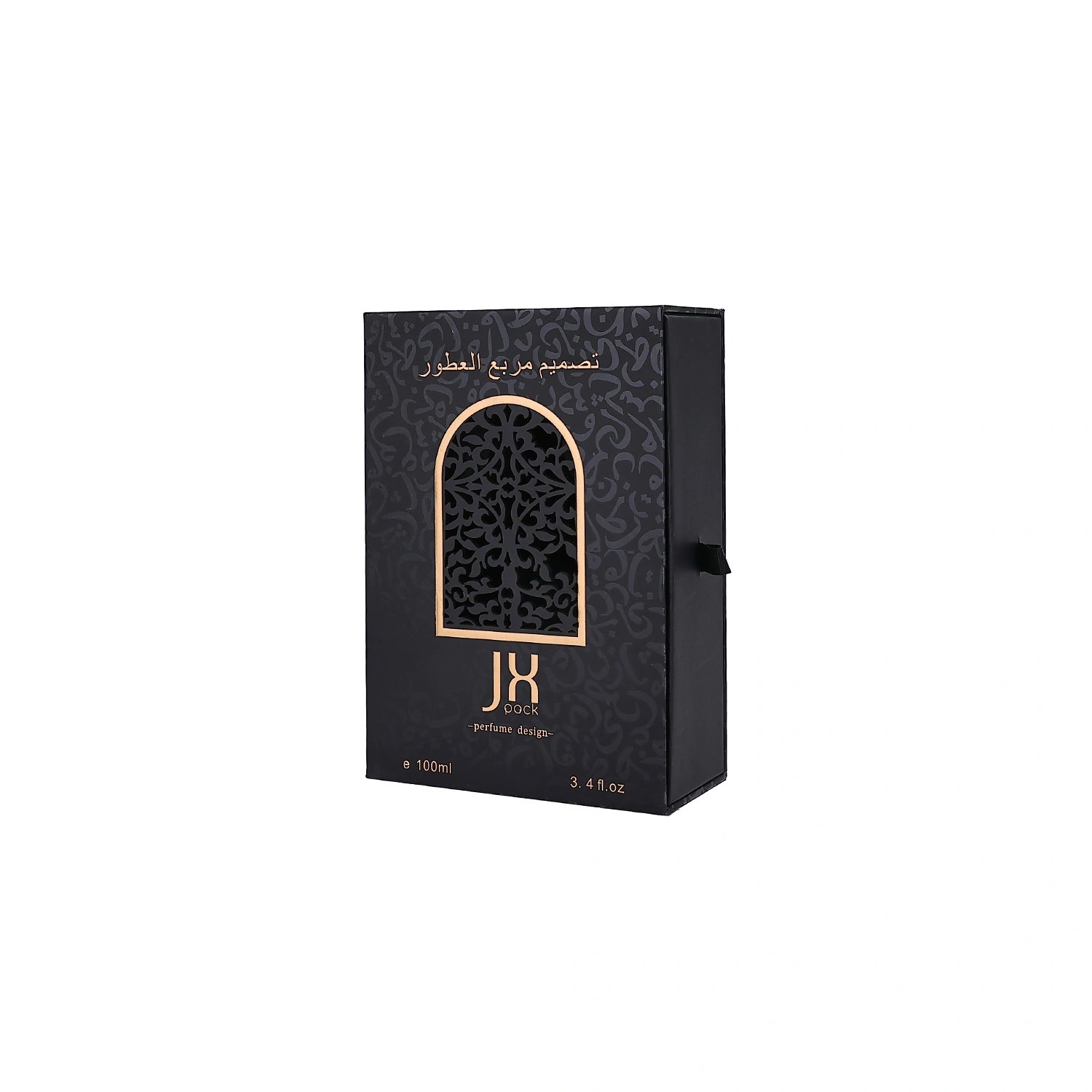

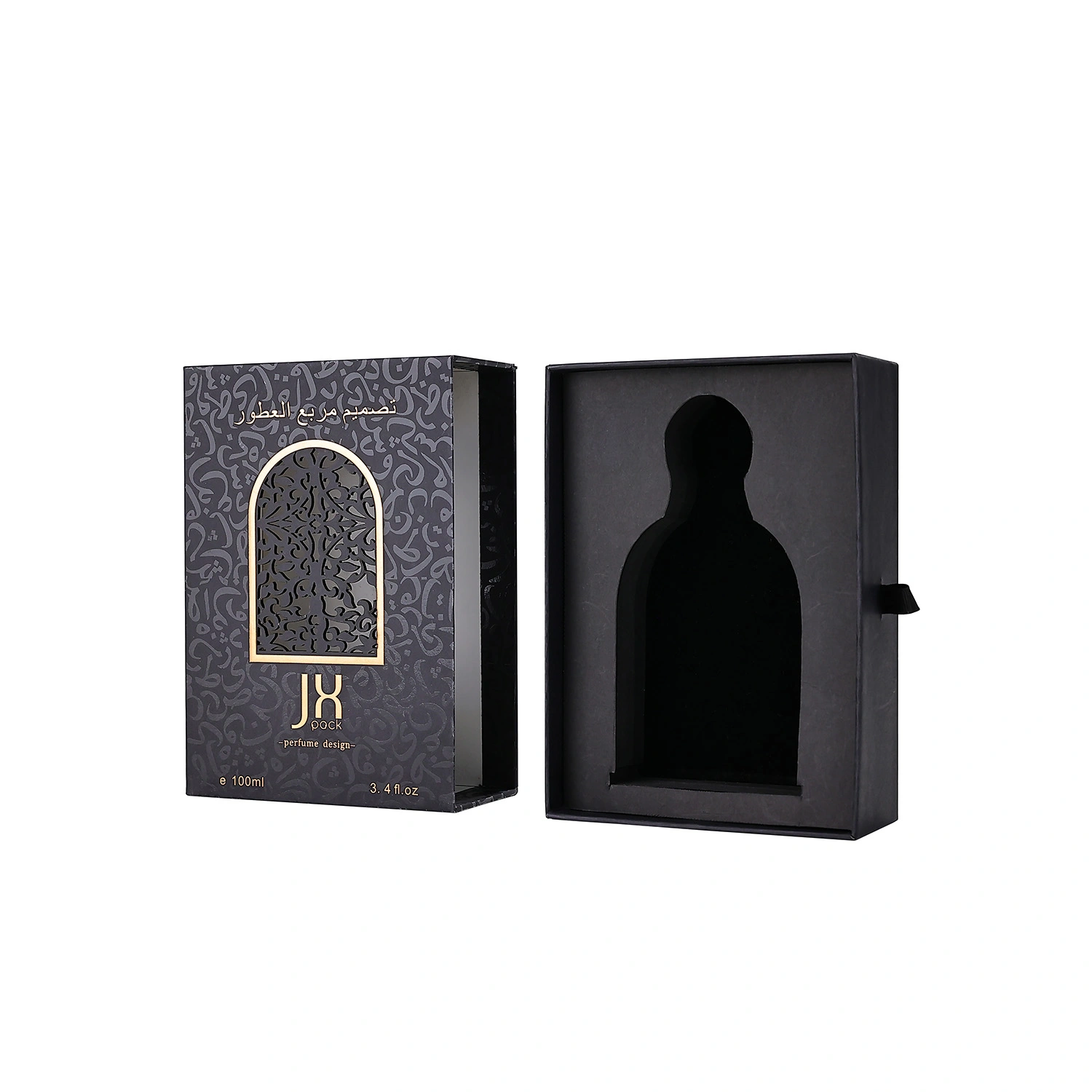

Sliding Box

Folding Carton

Box with Window

Child-proof Box

Mailer Box

Paper Bag

Gift Bag

Mylar Bag

Label Sticker

Lvory Paper

Coated Paper

CCNB

Double-offset Paper

Kraft Paper

Gold Paper

Black Paper

Special Paper

Corrugated Paper

Cardboard

Texture

Spot UV

Laser Engraving

Lamination

Hot Foil Stamping

Flocking

Embossing

Debossing

Die Cutting

3D

Pantone

CMYK

Digital Print

Paper Card Lining

Satin Lining

Blister Lining

Pearl Cotton Lining

EVA Lining

Paper Bag String

More Boxes, Same Budget:

How Flexible MOQ Works for You

MOQ is where freedom and smart spending come together. Instead of locking you into a fixed minimum, you choose the quantity that fits your plan—small runs for a new launch, limited editions for holidays, or a quick top‑up before you sell out. You get full‑quality, professional packaging without paying for boxes that just sit in storage.

Behind the scenes, setup costs—like tooling, color matching, and machine calibration—are almost the same whether you order a few hundred or a few thousand boxes. That means as you increase your quantity, your cost per box drops dramatically, so you often get “more”custom packaging for a very similar overall budget.

From Structural Design to Final Delivery

Custom Paper Box Samples and Production Cycles

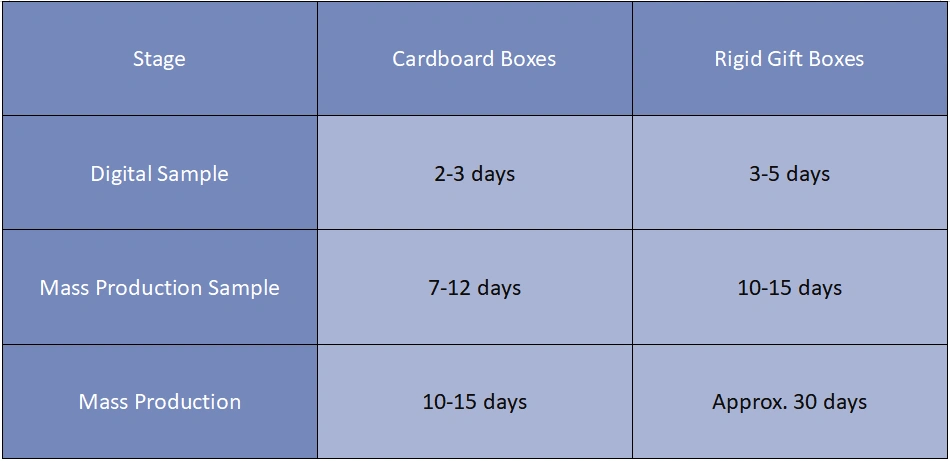

We begin with sample development, offering both digital and production-grade samples so you can review materials, printing, and structure before moving forward. Once approved, production moves to the mass manufacturing phase, where printing, finishing, cutting, and assembly are managed with expert care to ensure uniform color and quality.

For designs with special finishes or custom inserts, we coordinate each step precisely and provide flexible scheduling—such as partial or phased shipments—to help you meet launch timelines smoothly.

With streamlined workflow and close communication, Othilapak delivers packaging that combines speed, precision, and premium quality to keep your brand ahead in a fast-changing market.

FAQ Regarding Paper Packaging

Q: Do you have a minimum order quantity (MOQ)?

A: There is no fixed minimum order quantity, so you can start with small runs for new launches or seasonal campaigns. However, as quantity increases, the cost per box typically decreases, allowing you to get more packaging for a similar overall budget.

Q: Which industries do your packaging solutions cover?

A: Solutions are suitable for cosmetics, skincare, perfume, food, maternal & infant, daily necessities, pharmaceuticals, e‑commerce, toys, electronics, wine, and more. Each industry can be matched with tailored structures and materials for protection and branding.

Q: Can I get a sample before placing a bulk order?

A: Yes, both digital and press samples are available so you can check structure, color, and finishing before confirming mass production. This helps avoid errors and ensures the final packaging meets your expectations.

Q: Do you offer partial shipments or rush orders?

A: For urgent projects, we can usually arrange phased deliveries so that part of your order can be delivered earlier. Expedited service depends on current production capacity and project complexity, and we will evaluate this on a case-by-case basis.

Q: What customization options do you offer?

A: You can customize size, structure, material, printing, and special finishes such as foil stamping, embossing, spot UV, windows, and inserts. This makes it easy to create packaging that matches your brand image and product requirements.

Q: Can you help me choose the right box structure for my product?

A: Yes, structural and packaging specialists can recommend suitable types such as two-piece boxes, magnetic boxes, drawer boxes, folding cartons, or mailers based on product size, weight, and sales channel. This ensures the right balance of protection, cost, and presentation.