The global packaging industry stands at a critical juncture where environmental sustainability and commercial viability must converge. Post-Consumer Recycled (PCR) plastic packaging has emerged as a cornerstone solution for brands seeking to reduce their environmental footprint while meeting increasingly stringent regulatory requirements. However, determining the optimal PCR content percentage for specific packaging applications remains a complex challenge that requires careful consideration of material properties, performance requirements, regulatory compliance, and cost-effectiveness.

1. Understanding PCR Plastic Packaging

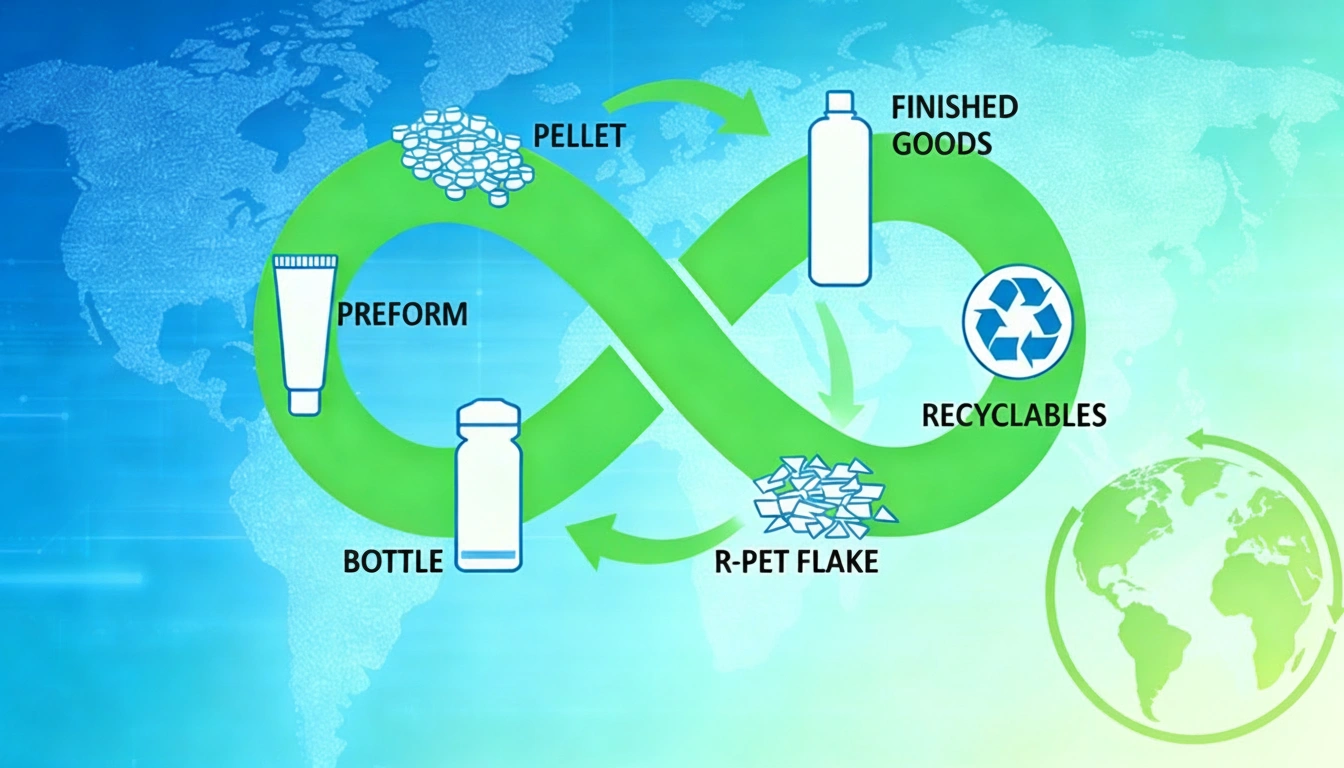

Post-Consumer Recycled (PCR) content refers to the percentage of packaging material made from recycled consumer plastics that have completed their lifecycle and been reprocessed into new materials. Unlike virgin plastics derived from petroleum feedstocks, PCR materials represent a circular economy approach by diverting waste from landfills and oceans while reducing dependence on fossil fuels. PCR is typically incorporated into packaging as a percentage of the total material composition, such as a plastic bottle with 30% PCR containing 30% recycled material and 70% virgin plastic.

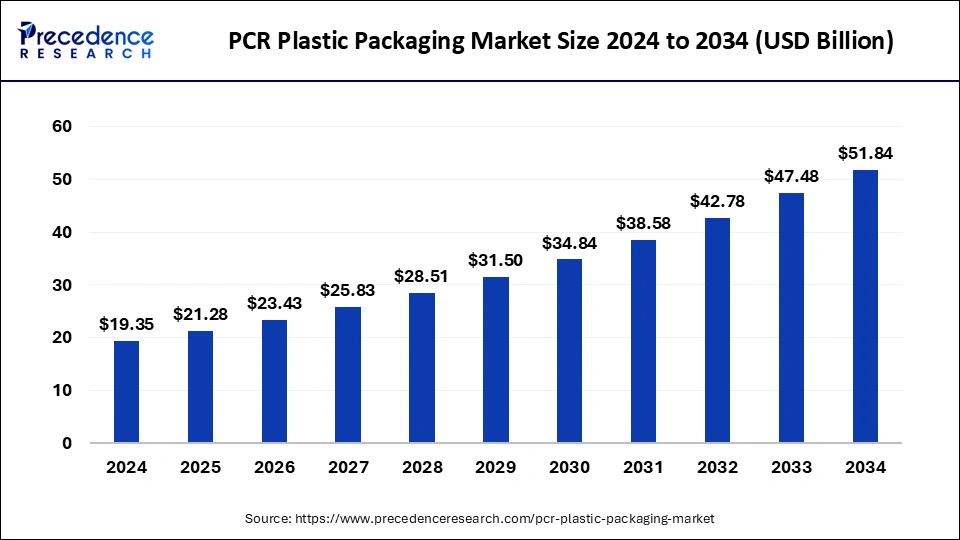

The average PCR content in plastic packaging has more than doubled among companies with stated sustainability goals, increasing from 5.3% in 2019 to 10.7% in 2023. This acceleration reflects both corporate sustainability commitments and evolving regulatory landscapes that incentivize or mandate minimum recycled content thresholds.

Types of PCR Materials

Two primary recycling methods produce PCR materials with distinct characteristics. Mechanical recycling involves physically processing post-consumer plastic waste through sorting, washing, shredding, melting, and reforming into new pellets. This method is more widely available and energy-efficient but may result in reduced clarity and performance characteristics compared to virgin resin. Only certain mechanically recycled grades receive FDA certification for food contact applications.

Chemical recycling breaks down plastic polymers to their molecular components and reconstructs them, yielding high-quality plastic that can meet rigorous standards for sensitive applications like food-grade or medical packaging. While chemical recycling produces materials nearly identical to virgin plastic in quality, the process remains less widespread and more energy-intensive than mechanical methods.

The FDA has approved several PCR plastic types for food contact applications, including post-consumer recycled linear low-density polyethylene (LLDPE PCR), polyethylene terephthalate (PET), and high-density polyethylene (HDPE), which can be used at varying percentages including up to 100% recycled content for many food applications.

2. The Regulatory Landscape Driving PCR Adoption

North American Regulations

California has established world-leading standards for minimum recycled content in plastic packaging. As of January 2022, plastic beverage bottles sold in California must contain at least 15% recycled plastic on average. This requirement escalates to 25% PCR by 2025 and 50% by 2030. Manufacturers failing to reach these thresholds face penalties of 20 cents for each pound of post-consumer resin (PCR) short of the target.

California’s regulatory framework extends beyond beverage bottles. The state mandates progressive increases in PCR content, with requirements rising by 5% every three years for beverage bottles and 10% every three years for all other rigid plastic containers until reaching a 50% threshold. Washington State follows a similar trajectory, requiring most beverage bottles to contain 15% PCR by 2023, 25% by 2026, and 50% by 2031.

New Jersey implemented requirements in January 2024 that single-use plastic beverage bottles contain at least 15% PCR content, while all other rigid plastic containers must contain at least 10% PCR. These levels increase by 5% every three years for beverage bottles and 10% every three years for other containers.

The United Kingdom introduced a Plastic Packaging Tax that creates financial disincentives for packaging with insufficient recycled content. Plastic packaging components containing less than 30% recycled plastic are subject to tax charges, while those meeting or exceeding the 30% threshold are exempt.

Source: https://www.tomra.com/about-tomra/circular-economy/ppwr-eu-packaging-regulation

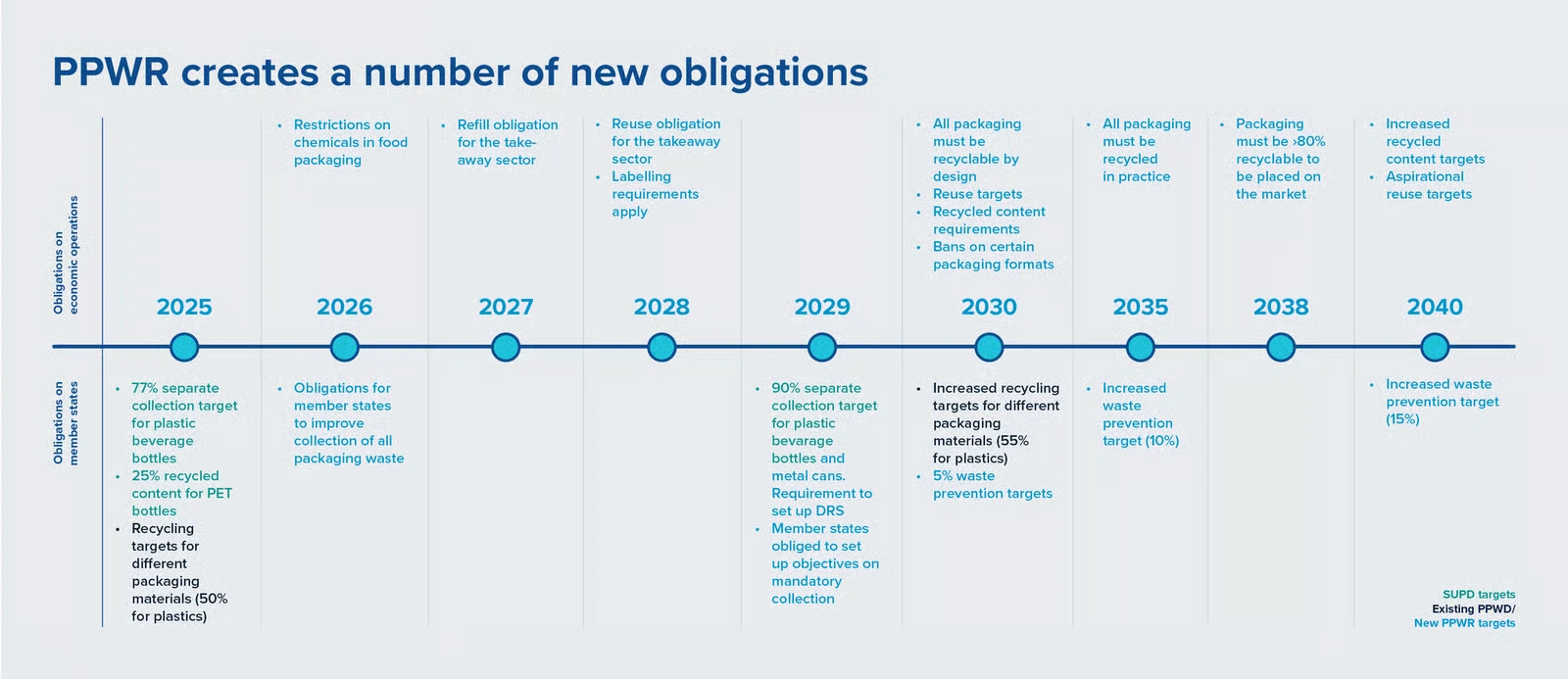

European Union Requirements

The European Union’s Packaging and Packaging Waste Regulation (PPWR) establishes comprehensive recycled content mandates that will reshape the packaging industry by 2030. By 2030, contact material packaging made from PET plastic (excluding beverage bottles) must contain 30% recycled material. Contact material packaging made from other plastics must contain 10% recycled material. PET beverage bottles must achieve 30% recycled content, while all other plastic packaging not mentioned in these categories must contain 35% recycled material.

The EU directive on single-use plastic products requires plastic bottles to contain at least 25% recycled plastic from 2025 and at least 30% recycled content by 2030. These regulatory targets are somewhat more lenient than California’s aggressive 50% by 2030 requirement.

Strategic Implications of Regulatory Thresholds

The convergence of regulations around the 30% PCR threshold is not coincidental. This percentage represents a strategic balance point where environmental benefits become substantial while maintaining technical feasibility across diverse packaging applications. Legislation within the EU and UK specifically designed taxes on single-use plastic products made with less than 30% recycled plastic to encourage recycling and decrease landfill diversion.

Consumer minds have shifted in favor of PCR flexible film, prompting manufacturers to increase PCR percentage step by step, with 30% initially serving as a practical entry point. Companies like Bostik manufacture PCR packaging using a minimum of 30% recycled plastic for cartridges and 35% for buckets, with ambitions to reach 100% PCR content packaging by 2030.

3. Material Properties: Comparing PCR Content Levels

Performance Characteristics at 30% PCR

Packaging incorporating 30% PCR content generally maintains performance characteristics close to virgin materials while achieving meaningful environmental benefits. This percentage allows manufacturers to balance sustainability goals with functional requirements across most packaging applications. Many companies have successfully implemented 30% PCR in their packaging portfolios, demonstrating that this level provides adequate mechanical strength, barrier properties, and aesthetic quality for commercial deployment.

Berlin Packaging developed new PET bottles incorporating 30% PCR plastic, exceeding California’s 25% PCR requirements while saving more than 116,000 pounds of virgin resin annually. The company simultaneously reduced bottle weight through lighter preforms, achieving a 21% reduction for 16-ounce bottles (from 43 to 34 grams) and 19% reduction for 26-ounce sizes (from 53 to 43 grams), saving an additional 62,000 pounds of plastic annually.

ProAmpac successfully used FDA-compliant film with PCR content equaling 25% of the overall structure for almond packaging, maintaining food-compliant requirements. In another application, the company added PCR to the outer print layer of a pet food retort pouch, meeting sustainability targets while withstanding high-temperature retort conditions and maintaining product shelf life. Both examples maintained high-quality graphics expected by consumers while meeting all barrier and structure requirements.

Unilever committed to integrating at least 25% PCR plastic in its packaging by 2025 but surpassed that target by 2021, achieving an average of 30% PCR plastic across its packaging portfolio. This achievement demonstrates that 30% PCR content is not only technically feasible but commercially scalable across diverse product categories and packaging formats.

Performance Considerations at Higher PCR Levels

As PCR content increases beyond 30%, manufacturers face progressively greater technical challenges related to material consistency, mechanical properties, and performance reliability. Recycled plastics may exhibit variations in material properties depending on the source materials and recycling process used, making quality prediction and control more challenging.

PCR resins often demonstrate inferior mechanical properties compared to virgin plastics, including reduced strength, durability, and heat resistance. These limitations can restrict suitability for certain high-performance applications. Mechanically recycled plastics may show slight reductions in strength, though they generally retain good toughness levels when processing is properly controlled.

One critical performance challenge relates to how much PCR can be incorporated while still meeting strength and functionality requirements. In some cases, packaging with 40% PCR might need to be made thicker than virgin film because recycled content can reduce strength and other performance requirements. This trade-off matters significantly because using more total material can undermine the goal of reducing virgin plastic consumption. The objective should be adding PCR at levels that truly minimize virgin feedstocks without driving up overall material use.

Careful monitoring of how PCR affects performance prevents scenarios where incorporating recycled content backfires by requiring additional virgin material to compensate for performance losses. Companies must evaluate whether the addition of PCR affects recyclability of the final product, which is also determined by the quality of recycled plastic used. Lower-quality PCR may reduce the ability to be recycled again, whereas higher-quality PCR content yields products that can be recycled multiple times after production and use.

Achieving 100% PCR Content

FDA-approved materials like Revolution’s recycled post-consumer linear low-density polyethylene (LLDPE PCR) can be used at 100% recycled content for many food applications, including dry, wet, raw, and cooked foods. This demonstrates that complete replacement of virgin plastic is technically feasible for certain polymer types and applications when proper recycling processes and quality controls are implemented.

However, 100% PCR content represents the most challenging scenario for maintaining consistent material properties and performance. Research on materials recovered from municipal recycling facilities (MRF) and processed into 100% PCR formulations found that samples made of recycled polyethylene (PE) and polypropylene (PP) demonstrated mechanical features like those of virgin polymers. In contrast, samples made of 100% recycled PET did not show completely satisfactory properties, displaying rather poor elastic modulus and ductility.

Studies on recycled PP from MRF-recovered bales tested at 25%, 50%, 75%, and 100% PCR-PP concentrations in extrusion blow molded bottles revealed performance variations across the PCR content spectrum. These findings suggest that achieving 100% PCR requires careful material selection, advanced processing techniques, and potentially acceptance of some performance trade-offs compared to virgin or blended formulations.

A mono-material polyethylene functional film tested through multiple recycling cycles showed tensile strength declining from 29.66 MPa (longitudinal) and 24.9 MPa (transverse) initially to 21.972 MPa and 19.222 MPa after recycling. Despite these reductions, the film still maintained good mechanical properties after the recycling cycle. However, a noticeable decline in barrier properties was observed after the second recycling.

The quality and consistency of PCR materials depend heavily on sophisticated quality control processes. Researchers developed a new degradation metric called Vdeg, derived from Van Gurp-Palmen plots of rheological data, to quantify the extent of degradation that polymers undergo during recycling. This metric allows manufacturers to assess PCR quality early in the evaluation process, identifying batches that may degrade faster or contain impurities and determining whether to blend with virgin plastics or add stabilizers to improve performance.

4. Environmental Impact Analysis

Carbon Footprint Reduction

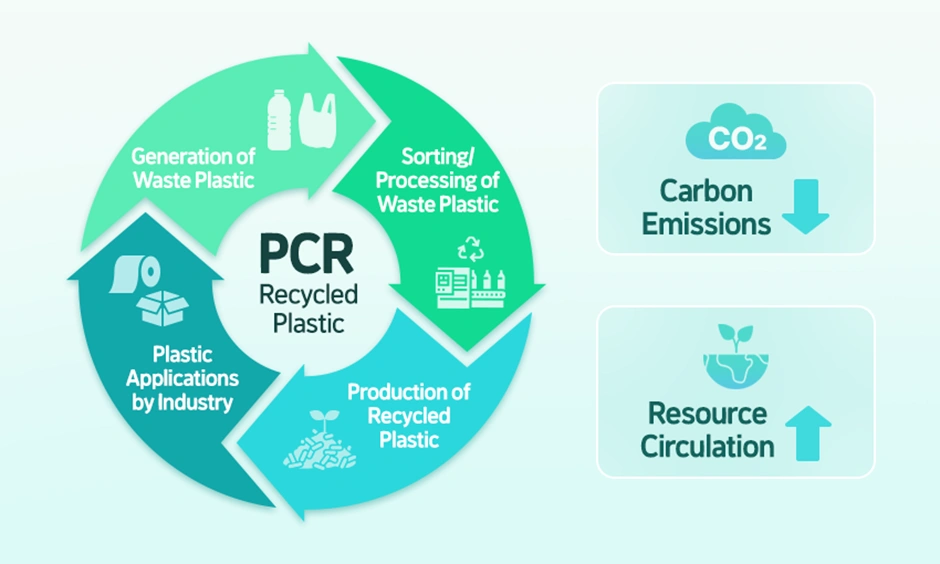

The environmental benefits of PCR plastic increase proportionally with recycled content percentage. Life cycle assessment (LCA) methodology evaluates environmental impacts throughout a product’s entire lifecycle, from raw material extraction to manufacturing, use, and end-of-life. For PCR packaging, LCA includes emissions associated with collecting, sorting, and processing recycled materials, as well as manufacturing the final packaging. This is compared to the carbon footprint of packaging made from virgin materials, which includes emissions from extracting and processing raw materials.product.

Using one ton of PCR plastic reduces carbon dioxide equivalent (CO2e) emissions by 79-86% compared to virgin plastic, though different types of PCR plastics have different carbon reduction potentials. Acer’s commitment to use 10,000 tons of PCR plastics by 2025 was estimated to reduce total emissions by 30,000 metric tons of CO2e. These substantial savings demonstrate the climate benefits of scaling PCR adoption across large product portfolios.

A study examining mono-material film with 10 weight percent circulating mass found that it could reduce CO2 emissions by 3,692.25 kilograms for every 1.0 ton of plastic products after four recycling cycles. This highlights the compounding environmental benefits of designing packaging for multiple recycling cycles.

Life cycle assessment data indicates strong evidence for reduced health risks with both a higher percentage of recycled content and a greater end-of-life recycling rate, resulting in approximately one day of healthy life saved per tonne of plastic packaging recycled. This finding quantifies the public health co-benefits of PCR adoption beyond direct environmental metrics.

Resource Conservation

PCR materials reduce the need for virgin plastic production, which is resource-intensive and contributes to environmental degradation. By reusing plastics that have already been consumed, manufacturers conserve natural resources and decrease the amount of plastic waste that ends up in landfills or oceans, contributing to a more sustainable circular economy.

Every ton of waste plastic recycled is equivalent to saving six tons of oil, reducing carbon dioxide emissions by three tons, and producing 800 kilograms of recycled plastic. These resource conservation multipliers demonstrate that the benefits of recycling extend far beyond waste diversion to encompass energy security and raw material availability.

The lightweight and compact nature of PCR materials can lead to reduced logistics and transportation costs, making PCR not only an environmentally-friendly option but also a cost-effective one. This dual benefit strengthens the business case for PCR adoption.

Transportation and Supply Chain Considerations

To balance and optimize cost efficiency, including material, transportation, and carbon footprint of PCR plastics, the source of recycled material should ideally come from local or nearby regions. However, ensuring a stable supply of PCR plastics may require broader sourcing, potentially from more distant locations. Studies indicate that emissions from transportation during PCR plastic recycling within the same region are relatively small compared to other lifecycle stages.

Companies continue studying the entire lifecycle of PCR plastic’s environmental impacts and collaborate with suppliers to lower carbon emissions whenever possible. This holistic approach recognizes that optimizing one aspect of the supply chain should not inadvertently increase impacts elsewhere.

Source:https://news.lgdisplay.com/en/2024/12/lg-display-reduces-carbon-emissions-by-520-tons-with-eco-friendly-packaging/?ckattempt=1

5. Technical Challenges and Solutions

Quality Consistency and Contamination

One of the most significant challenges with using PCR in food packaging, medical, dental, and beverage applications is ensuring that recycled materials meet necessary safety and regulatory standards. Contamination risks, inconsistent material quality, and traceability concerns can make it difficult to use PCR materials in applications where sterility and purity are critical.

The FDA’s main safety concerns with PCR plastic materials in food-contact articles include potential contaminants from the PCR material and the possibility that adjuvants (processing aids, polymer production aids) from the PCR material may not be approved for food-contact use. To address these concerns, FDA considers each proposed use of recycled plastic on a case-by-case basis and issues informal advice as to whether the recycling process produces PCR plastic of suitable purity for food-contact applications.

Studies have found 906 chemicals in plastic containers, with 148 considered highly toxic. PCR samples often contain more harmful chemicals than virgin plastics. Rigorous checking and testing of containers is necessary to maintain high safety standards. Bad substances might migrate from containers into food, especially under heat exposure.

The recycling process itself can introduce aesthetic imperfections. PCR plastics may exhibit color variations and minor flaws due to recycling procedures. While these may not affect functionality, they can impact consumer perception and brand presentation.

Advanced Recycling Technologies

Developing advanced recycling technologies helps overcome quality limitations of traditional mechanical recycling. Despite added reclamation capacity, the United States will still fall short in meeting 2025 plastics packaging goals, especially for PET, unless collection rates and advanced recycling capabilities increase significantly. This gap highlights the need for continued investment in recycling infrastructure and technology innovation.

Fluorescence-based analytical techniques have been developed to quantitatively determine recycled content in plastic packaging. Bathochromic shifts resulting from aggregation of fluorescent brightener 4,4′-bis(2-benzoxazolyl) stilbene (BBS) in commodity plastics at loadings of 0.5 weight percent or less can systematically quantify simulated recycled content. This analytical capability supports verification of recycled content claims and enables quality control throughout the supply chain.pubs.

Cost Considerations

While PCR materials offer environmental benefits, they are not always more cost-effective than virgin plastics. The processing and purification required to ensure PCR materials meet industry standards can add to overall costs. Additionally, limited availability of high-quality PCR materials can drive up prices, making it a less attractive option for some companies.

Balancing the desire for sustainability with the need to maintain cost-effectiveness represents a significant challenge. However, as regulatory pressures increase and PCR production scales up, economies of scale may improve the cost competitiveness of recycled materials relative to virgin plastics.

Companies implementing 30% PCR often find this percentage provides an optimal balance between environmental benefits and cost management. The 30% threshold allows meaningful carbon footprint reduction while maintaining material costs within acceptable ranges for most commercial applications.

6. Application-Specific Considerations

Food Contact Applications

Regulatory compliance for food-contact packaging requires stringent safety verification. The FDA requires manufacturers to follow a clear process, sending a Food Contact Notification (FCN) before using new materials and adhering to Code of Federal Regulations Title 21, which lists safety rules for food packaging. Manufacturers must provide safety data about PCR plastic, with FDA reviewing chemicals and intended uses.

The FDA evaluates how resin makers recycle plastic to ensure contaminants don’t enter food products. If the FDA approves the process, they issue a No Objection Letter indicating the plastic is safe for specified food applications. Factories must have appropriate equipment and implement strong quality checks to maintain packaging safety.

Flexible pouches with FDA-approved PCR plastics like PET, HDPE, and LLDPE are considered safe for food contact when proper protocols are followed. Some factories use FDA-safe film with 25% PCR for products like almond packaging, while others produce pet food pouches with PCR that can withstand heat and maintain long shelf life.

Beverage Packaging

Beverage packaging represents one of the most mature applications for high PCR content. Polyethylene terephthalate (PET) bottle-to-bottle recycling for the beverage industry has evolved over 30 years since the FDA first began certifying PCR PET production processes as compliant for beverage packaging production. This long history has established robust processes for producing food-grade recycled PET suitable for direct beverage contact.

Major beverage manufacturers have made substantial pledges to reduce environmental footprints by incorporating recycled content. These commitments drive demand for high-quality PCR PET and incentivize investment in recycling infrastructure.

The 50% PCR requirement for California beverage bottles by 2030 represents a world-leading standard. Achieving this aggressive target requires dramatic strengthening of collection rates, sorting efficiency, and processing capacity throughout the recycling value chain.

Flexible Packaging

PCR flexible packaging can be tailored to meet specific branding needs, allowing businesses to maintain visual appeal and functional requirements while demonstrating sustainability commitments. Customizability enables brands to incorporate recycled content without sacrificing the aesthetic and marketing elements that differentiate products in competitive markets.

The lightweight nature of flexible packaging amplifies the environmental benefits of PCR incorporation. Since flexible packaging uses less material overall compared to rigid alternatives, substituting recycled content for virgin plastic in these applications yields proportionally greater sustainability improvements.

Consumer acceptance of PCR flexible packaging has grown substantially, with purchasers increasingly valuing sustainability attributes. This shift in consumer preferences creates market pull for brands to adopt higher recycled content percentages.

Non-Food Applications

Beyond food and beverage packaging, PCR plastics find applications across diverse industries including electronics, consumer products, and industrial packaging. Acer incorporated 17% PCR plastic in computers and displays by 2022, with targets to reach 20-30% by 2025. Electronics applications may have less stringent purity requirements than food contact, potentially enabling higher PCR percentages while maintaining adequate performance.

Personal care and cosmetics packaging increasingly incorporates PCR content as brands seek to enhance sustainability credentials. Bostik’s PCR packaging manufactured with minimum 30% recycled plastic for cartridges demonstrates feasibility across adhesive and sealant product lines.

7. Decision Framework: Choosing Between 30% and 100% PCR

Factors Favoring 30% PCR Content

Starting with 30% PCR content offers several strategic advantages for companies new to recycled packaging or operating in highly regulated sectors. This percentage meets or exceeds many current regulatory thresholds while maintaining material properties close to virgin plastic. The 30% level provides meaningful environmental benefits without the technical complexity and supply chain challenges associated with higher PCR percentages.

Manufacturing processes and equipment typically require minimal modification to accommodate 30% PCR blends. Existing quality control procedures, printing capabilities, and downstream processing equipment generally function effectively with 30% recycled content. This compatibility reduces capital investment requirements and implementation timelines.

Material availability and cost considerations favor 30% PCR content. Supply chains for 30% PCR blends are more established than those for very high recycled content materials. Pricing tends to be more competitive at moderate PCR percentages where demand from multiple manufacturers supports economies of scale.

Performance reliability is more predictable at 30% PCR. Batch-to-batch consistency tends to be better when virgin plastic constitutes the majority of the formulation, buffering variations in recycled material quality. This consistency matters particularly for automated high-speed packaging lines where material property variations can cause equipment malfunctions and production downtime.

Factors Favoring Higher PCR Content

Companies with aggressive sustainability goals or operating in markets with stringent environmental standards may pursue PCR content substantially above 30%. California’s 50% PCR requirement for beverage bottles by 2030 exemplifies regulatory drivers pushing beyond moderate recycled content thresholds.

Brands seeking differentiation through sustainability leadership can leverage high PCR content as a competitive advantage. Consumer segments increasingly prioritize environmental attributes when making purchasing decisions, creating market opportunities for products with exceptional recycled content.

Applications where aesthetic imperfections or slight performance variations are acceptable enable higher PCR percentages. Industrial packaging, shipping materials, and certain consumer products can tolerate the minor inconsistencies that sometimes accompany very high recycled content.

Vertically integrated companies with control over their recycling supply chains may achieve higher PCR percentages more feasibly than those relying on third-party suppliers. Internal recycling operations enable tighter quality control and material specifications optimized for specific end-use requirements.

Incremental Approach to PCR Adoption

Many successful PCR implementations follow an incremental strategy, starting with 30% content and progressively increasing percentages as technology, supply chains, and organizational capabilities mature. This phased approach allows companies to build technical expertise, develop supplier relationships, and refine processes before committing to very high recycled content levels.

Bostik’s roadmap exemplifies this progression, beginning with minimum 30% PCR for cartridges and 35% for buckets, with some products already reaching 80% recycled content and ambitions to achieve 100% PCR packaging by 2030. This timeline provides flexibility to address technical challenges as they emerge while maintaining steady progress toward ultimate sustainability goals.

Initial implementations at moderate PCR percentages generate learnings about material behavior, processing requirements, and quality control that inform subsequent increases. Companies can identify specific challenges—whether related to strength, clarity, odor, or processing characteristics—and develop targeted solutions before scaling to higher recycled content.

Source: https://www.precedenceresearch.com/pcr-plastic-packaging-market

8. Industry Trends and Future Outlook

Accelerating PCR Adoption Rates

The dramatic increase in average PCR content from 5.3% in 2019 to 10.7% in 2023 demonstrates accelerating industry adoption. This doubling within four years suggests a tipping point where PCR transitions from niche specialty to mainstream standard.

Corporate sustainability commitments increasingly incorporate specific PCR targets. Major brands publicly pledge to achieve defined recycled content percentages by specified dates, creating accountability and driving systematic progress. These commitments aggregate into substantial demand signals that justify investments in recycling infrastructure and technology.

Supply Chain Development

Despite progress, significant supply gaps remain. The United States will fall short of meeting 2025 plastics packaging goals without substantial increases in collection rates and advanced recycling capabilities. Addressing these gaps requires coordinated investment across the value chain, from improved collection systems through advanced sorting technology to enhanced processing capacity.

Regional variations in recycling infrastructure create uneven PCR availability. Companies may need to source materials from distant locations to ensure stable supply, though this increases transportation emissions and complexity. Developing localized recycling ecosystems would optimize both environmental and economic performance.

Quality standards for PCR materials continue evolving. New analytical techniques like the Vdeg degradation metric enable more sophisticated assessment of recycled material quality, supporting better matching of PCR grades to specific applications. These tools help optimize the balance between recycled content percentage and performance requirements.

Technological Innovation

Advanced recycling technologies promise to overcome current limitations of mechanical recycling. Chemical recycling produces materials with properties nearly identical to virgin plastic, potentially enabling 100% PCR content across broader application ranges. As these technologies scale and costs decline, they may unlock applications currently restricted to virgin or low-PCR-content materials.

Additive technologies that enhance PCR performance represent another innovation frontier. Research demonstrates that applying coupling agents to PCR plastics composed of polypropylene and polyethylene can result in 53.9% increases in tensile strength. These enhancement technologies may enable higher PCR percentages without performance compromises.

Design for recyclability principles are increasingly incorporated into packaging development. Creating packaging that maintains quality through multiple recycling cycles amplifies environmental benefits and supports truly circular material flows.

Regulatory Evolution

Regulatory requirements will continue tightening. California’s progression from 15% to 50% PCR for beverage bottles between 2022 and 2030 illustrates the trajectory. The European Union’s 2030 targets ranging from 10% to 35% depending on application establish a regulatory floor that will rise over time.

Harmonization of standards across jurisdictions would simplify compliance for global brands. Currently, companies must navigate divergent requirements across California, Washington, New Jersey, the EU, and the UK. Alignment around common thresholds and timelines would reduce complexity.

Verification and enforcement mechanisms are becoming more sophisticated. Analytical techniques for quantifying recycled content enable regulatory authorities to verify compliance claims. This capability supports credible implementation of recycled content mandates and taxes.

9. Conclusion

Choosing the right PCR content percentage for plastic packaging requires careful analysis of multiple interdependent factors including regulatory requirements, material properties, application specifications, supply chain capabilities, cost considerations, and sustainability objectives. The practical differences between 30% and 100% PCR content are substantial and consequential for both environmental performance and commercial viability.

Thirty percent PCR content represents a proven, accessible entry point that meets most current regulatory thresholds while maintaining material properties close to virgin plastic. This percentage offers meaningful environmental benefits with manageable technical complexity and established supply chains. Companies implementing 30% PCR can demonstrate sustainability progress while maintaining performance reliability and cost competitiveness.

Moving beyond 30% toward 100% PCR content amplifies environmental benefits proportionally, with carbon footprint reductions of 79-86% per ton of recycled plastic compared to virgin material. However, higher PCR percentages introduce greater technical challenges related to material consistency, mechanical properties, and processing requirements. Successful implementation of very high recycled content demands advanced recycling technologies, sophisticated quality control, and potentially acceptance of some performance trade-offs.

The optimal PCR content percentage varies by application, with food-contact packaging requiring more stringent purity standards than industrial applications. Beverage bottles have successfully incorporated high PCR percentages thanks to 30 years of FDA-approved recycling processes. Flexible packaging offers unique opportunities for recycled content given its light weight and evolving consumer acceptance.

An incremental approach starting with 30% PCR and progressively increasing percentages as capabilities mature represents a pragmatic strategy for many companies. This phased progression allows organizations to build expertise, refine processes, and develop supply relationships while making steady sustainability progress.

The trajectory is clear: regulatory requirements will continue tightening, consumer expectations will continue rising, and PCR content percentages will continue increasing across the packaging industry. Companies that develop robust capabilities for incorporating recycled content will be well-positioned for this evolving landscape. Those that delay risk facing disruptive requirements without adequate preparation.

Ultimately, the choice between 30% and 100% PCR content should align with specific organizational capabilities, application requirements, market positioning, and sustainability ambitions. Both percentages offer valid pathways toward circular economy goals, with 30% representing an achievable near-term standard and higher percentages serving as aspirational targets that drive continued innovation. The packaging industry’s collective progress toward these goals will significantly influence global plastic waste reduction and climate change mitigation efforts for decades to come.

FAQs

What is PCR content in plastic packaging?

Post-Consumer Recycled (PCR) content refers to the percentage of packaging material made from recycled consumer plastics that have completed their lifecycle and been reprocessed into new materials. For example, a bottle with 30% PCR contains 30% recycled material and 70% virgin plastic.

Why is 30% PCR content so common in packaging?

The 30% threshold represents a strategic balance where environmental benefits become substantial while maintaining technical feasibility across diverse packaging applications. Many regulations, including the UK’s Plastic Packaging Tax, specifically target this percentage, and it allows manufacturers to maintain performance characteristics close to virgin plastic.

What are the main differences between 30% and 100% PCR content?

Packaging with 30% PCR generally maintains performance characteristics close to virgin materials with predictable quality and established supply chains. In contrast, 100% PCR content amplifies environmental benefits but introduces greater technical challenges related to material consistency, mechanical properties, and may require thicker packaging to compensate for reduced strength.

Is PCR plastic safe for food contact applications?

Yes, when properly approved by the FDA. FDA-approved PCR materials like PET, HDPE, and LLDPE can be used at varying percentages, including up to 100% recycled content for many food applications. The FDA evaluates each recycling process to ensure contaminants don’t enter food products and issues No Objection Letters for approved uses.

What are the main challenges of using high PCR content?

High PCR content faces challenges including quality consistency variations, potential contamination risks, reduced mechanical properties compared to virgin plastic, aesthetic imperfections like color variations, and higher costs due to processing and purification requirements. Some packaging with 40% or higher PCR may need to be made thicker to maintain strength requirements.

Should companies start with 30% PCR or aim directly for 100%?

Most successful implementations follow an incremental strategy, starting with 30% content and progressively increasing percentages as technology, supply chains, and organizational capabilities mature. This phased approach allows companies to build technical expertise and refine processes before committing to very high recycled content levels, as demonstrated by companies like Bostik that began with 30% and are working toward 100% by 2030.