In the global beauty industry, packaging is far more than a container. It is the first touchpoint between a brand and its customers, a silent ambassador that communicates quality, values, and identity before a product is even opened. In today’s marketplace, this first impression is increasingly tied to a single question: is it sustainable?

Among the many solutions advancing sustainability, recyclable packaging has emerged as a leading direction for cosmetics. Unlike niche alternatives, recyclable materials integrate more easily into existing waste systems while helping reduce reliance on virgin resources. They offer a practical path for beauty brands to align with environmental commitments without sacrificing scalability or consumer appeal.

Still, making the transition to recyclable packaging is not simple. Regulations differ across countries, consumer understanding of “recyclable” varies, and the design must balance beauty with technical recyclability. Costs and supply chain dynamics further complicate the equation. For many brands, the challenge lies not in recognizing the need but in navigating how to implement recyclable packaging at scale without compromising product integrity or profitability.

At Othilapak, we understand these complexities. With deep expertise in cosmetic packaging and a one-stop service model that integrates design, compliance, and production, we help brands turn recyclable packaging into a competitive advantage. In this blog, we will explore why recyclable packaging matters, the regulatory landscape shaping its adoption, the design challenges it presents, case studies of leading and indie brands, consumer insights, and how beauty brands can adopt sustainable practices.

1. Why Recyclable Packaging Matters in Cosmetics

The cosmetics sector is highly competitive, with products competing for attention in saturated retail and online environments. Packaging has always been central to differentiation, but in today’s world, recyclable packaging elevates the role from brand identity to brand responsibility.

Regulations Driving Change

Governments worldwide are tightening rules to reduce packaging waste and promote circularity. The European Union’s Circular Economy Action Plan mandates that all packaging must be reusable or recyclable by 2030. In the United States, several states have introduced Extended Producer Responsibility (EPR) legislation that requires brands to fund or manage the recycling of the packaging they place on the market. Japan enforces the Containers and Packaging Recycling Law, compelling companies to meet recycling quotas and invest in waste recovery systems.

For cosmetics brands, these rules are not optional—they are market access requirements. Non-compliance could mean limited distribution, reputational damage, or costly redesigns. Investing in recyclable packaging early allows brands to avoid disruptions and align globally across diverse regulatory systems.

Consumer Demand and Perception

Consumers—especially younger generations—expect brands to demonstrate environmental stewardship. Surveys show that 72% of millennials and Gen Z consumers consider a brand’s sustainability practices when making beauty purchases, and more than half are willing to pay a premium for eco-friendly packaging. In cosmetics, where packaging can account for a majority of environmental impact, the stakes are especially high.

A moisturizer packaged in recyclable PET plastic or a perfume housed in a recyclable glass bottle communicates values as strongly as any marketing campaign. Packaging is a physical symbol of sustainability, influencing purchasing decisions and building loyalty.

ESG and Corporate Responsibility

For large companies, recyclable packaging is also integral to Environmental, Social, and Governance (ESG) strategies. Investors now measure companies not only by revenue growth but also by their sustainability performance. Multinationals like L’Oréal and Estée Lauder have published ambitious sustainability roadmaps, with recyclable packaging as a cornerstone.

Indie beauty brands leverage recyclable packaging as a differentiator. Without large advertising budgets, they use eco-friendly packaging to project authenticity, attract conscious consumers, and compete against larger players.

Practicality vs. Alternatives

While biodegradable and compostable packaging options attract attention, they often require specialized conditions to decompose properly. Recycling, by contrast, works within existing systems, making it the most scalable and immediate solution. For brands seeking to create real-world impact while managing costs, recyclable packaging represents the pragmatic middle ground.

At Othilapak, we view recyclable packaging not as a compromise but as a commitment—a tangible way to merge design, practicality, and sustainability into every beauty product.

2. Regulatory Landscape and Global Standards for Recyclable Packaging

Sustainability goals for recyclable packaging are inextricably linked to an evolving and often complex regulatory landscape. Global beauty brands must navigate diverse standards, harmonize packaging designs, and ensure compliance—making the challenge significant for any internationally distributed product.

European Union Regulations

The EU sets some of the most aggressive rules, requiring by 2030 that all packaging placed on the market is reusable or recyclable in an economically viable way under the Packaging and Packaging Waste Regulation (PPWR). Key mandates include minimum recycled content percentages for most packaging types, strict weight/volume limitations to avoid unnecessary packaging, explicit bans on select single-use formats, and extended producer responsibility (EPR) fee modulation based on recyclability performance grades. Furthermore, packaging must meet specific grades—grade C or above by 2030, rising to grade B or above by 2038—to qualify as recyclable, with clear design-for-recycling criteria established by delegated acts.

United States: Fragmented but Evolving

The regulatory landscape in the US is more fragmented, varying widely between states. California, Oregon, and Maine have notably advanced Extended Producer Responsibility (EPR) laws. These laws shift recycling costs to producers and impose reporting, labeling, recycled-content mandates, and financial penalties for noncompliance. California’s law goes further, requiring all packaging to be recyclable or compostable by 2032, with mandatory recycled content in plastic bottles. National beauty brands must design packaging to meet the strictest state standards to avoid distribution conflicts and compliance risks.

Japan: Efficient, Producer-Focused Compliance

Japan enforces an efficient recycling regime led by the Containers and Packaging Recycling Law. Manufacturers must recycle a set percentage of their packaging waste annually and collaborate with certified recycling organizations. Labeling requirements under the Act on the Promotion of Sorted Collection and Recycling of Containers and Packaging support consumer sorting, with clear instructions mandated at the product level. Western brands must adapt packaging to local rules, prioritize refillability and recyclability, and utilize labeling icons to guide consumers.

Canada, South Korea, and Australia: Global Alignment

Canada’s provinces—like British Columbia and Manitoba—have transitioned to full EPR programs, making producers solely responsible for recycling and recovery costs, with harmonized recycling lists impacting national brand strategies. South Korea mandates separate collection marking of recyclable packaging according to material type, and restricts certain colored plastics, raising the bar for harmonized global packaging. Australia similarly ramps up waste and recycling targets in line with global best practice.

International Standards and Harmonization

The Global Recycled Standard (GRS) is a voluntary, internationally recognized certification for tracking and verifying recycled content in products, serving as a benchmark for global brands. Brands use this and verified systems to ensure transparency and build trust wherever they operate.

Meeting sustainability goals in recyclable packaging requires beauty brands to monitor fast-changing global regulations, harmonize packaging for international distribution, and adapt quickly to stricter standards, new labeling requirements, and EPR laws. Staying ahead means investing heavily in design, compliance expertise, and collaboration with local partners in every market.

3. Design Challenges in Recyclable Packaging

Designing recyclable packaging for cosmetics is challenging due to the industry’s need to balance functionality, aesthetics, and sustainability. Below is a structured look at key design challenges and solutions:

Mixed Materials Complexity

Cosmetic packaging often incorporates multiple materials—plastics, metals, glass—which provide functional benefits but complicate recycling. Items such as pump dispensers or compacts can contain metal springs, multilayered plastics, and rubber, making mechanical separation difficult. The industry trend is toward mono-material solutions, where entire packages are designed from one material to streamline recycling. Polypropylene (PP), polyethylene (PE), and PET are increasingly favored for their recyclability and performance.

Surface Treatments and Aesthetics

High-end finishes like metallic coatings, frosted effects, and colored plastics are essential for brand differentiation, especially in beauty. Unfortunately, treatments such as film laminations and metallization impede sorting and processing at recycling facilities. To maintain shelf appeal without sacrificing recyclability, brands are turning to recyclable coatings (e.g., special UV coatings that are proven recyclable), natural colorants, and minimalist design, focusing on brand storytelling through sustainable aesthetics.

Functional Performance

Cosmetic packaging must protect sensitive formulations, assure hygiene, and offer convenience with pumps, airless containers, or droppers. These added features often introduce non-recyclable components (springs, elastomers, complex valves). Refillable modular designs—like pods inside reusable outer shells—are growing in popularity, as are systems engineered for easy disassembly to ensure that core materials enter recycling streams.

Balancing Beauty and Responsibility

Brands cannot ignore the visual allure central to cosmetics. Designers, engineers, and sustainability specialists are collaborating to blend elegant presentation with “design for recycling” principles. Approaches include:

Prioritizing mono-material packaging and modular components

Using minimalist graphics and compostable labels

Offering refillable options that keep outer packaging out of landfills

Othilapak’s Role

At Othilapak, the focus is precisely on helping brands achieve this equilibrium. By guiding brands toward compatible materials, innovative recyclable surface finishes, and modular, refillable designs, the firm enables clients to maintain premium aesthetics while supporting recycling compliance and circularity goals.

Key Industry Solutions

Mono-material Packaging: Transitioning toward packaging made entirely of one resin (like 100% PP or PET), allowing easy mechanical recycling.

Refillables: Durable cases with replaceable pods, reducing waste and boosting consumer loyalty.

Sustainable Aesthetics: Use of natural colors, recyclable coatings, or embossed details to achieve visual impact without plastic contamination.

Disassemblable Designs: Packaging engineered for easy separation of recyclable elements to lower contamination in waste streams.

Effective design for recyclable cosmetic packaging thus requires a multi-disciplinary approach, blending form, function, and circularity without losing the essence of luxury that underscores the beauty sector.

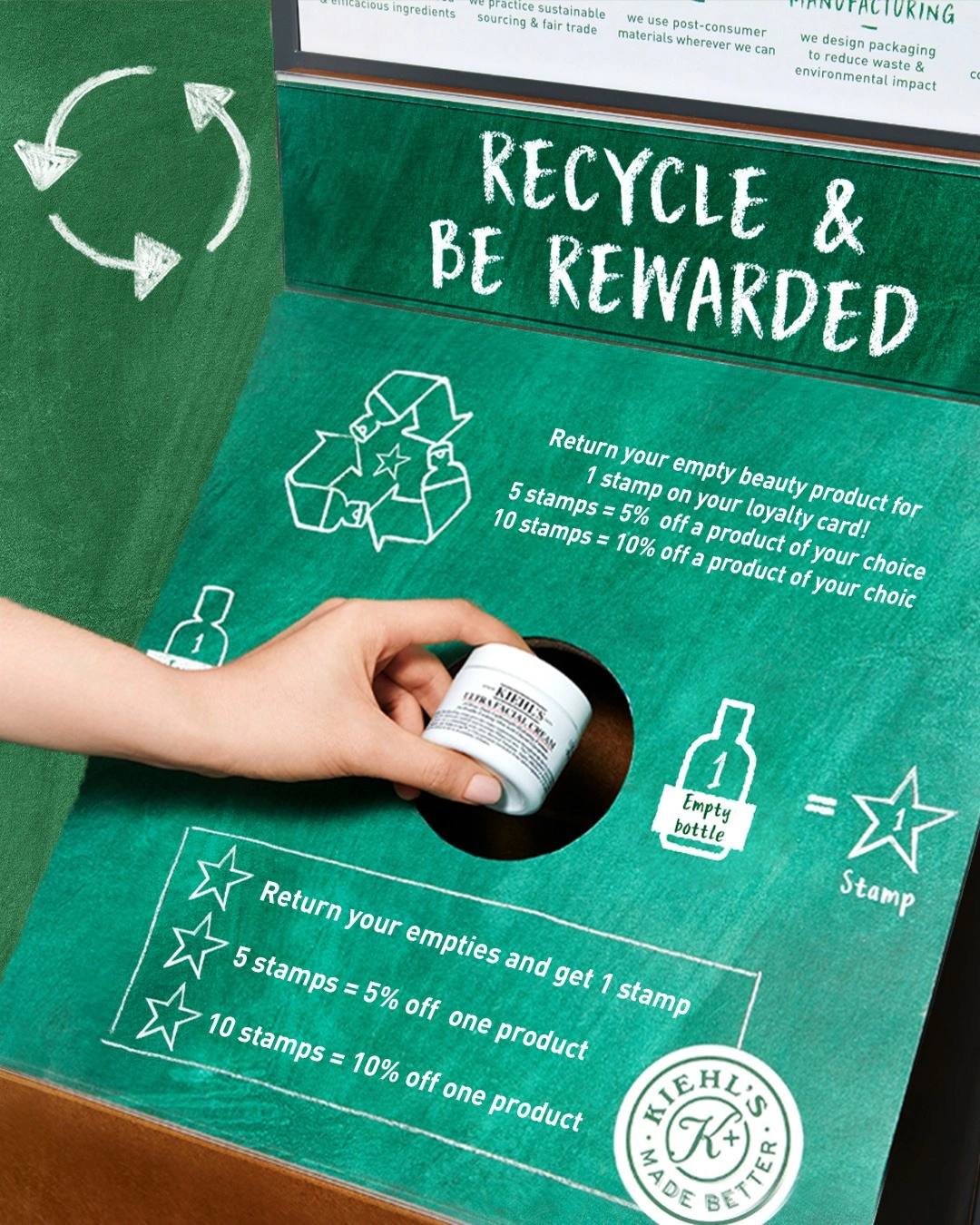

4. Case Studies: Leading Beauty Brands Going Recyclable

Leading beauty brands are making bold moves toward recyclable packaging by setting ambitious goals, investing in innovative materials, and engaging consumers through education and transparency. Here are the latest case studies illustrating their approaches and successes.

Global Leaders

L’Oréal

By 2025, L’Oréal expects 100% of its plastic packaging to be refillable, reusable, recyclable, or compostable. The “L’Oréal for the Future” program sets clear milestones: by 2025, 50% of plastics will be recycled or bio-sourced, with a goal of 100% by 2030. Packaging innovation includes partnerships with Carbios for enzymatic recycling technology, launching carton-based cosmetic tubes with Albéa, and developing recyclable paper bottles. Garnier has achieved 100% recycled PET use in shampoo bottles, and refills are promoted for leading product lines like Elsève.

Estée Lauder Companies

Across nearly two dozen brands—including Clinique and Aveda—ELC targets 75–100% recyclable, refillable, reusable, or recoverable packaging by 2025. The latest sustainability report shows 71% of packaging meets this standard, with significant use of post-consumer recycled (PCR) materials and Forest Stewardship Council–certified cartons. Agreements with SK Chemicals introduce advanced recycled materials and chemical recycling to boost circularity.

Shiseido (Japan)

Shiseido’s “Sustainable Beauty Actions” focus on mono-material designs and refillable packaging. By 2024, 76% of packaging had switched to sustainable, recyclable formats—including glass and PET. Shiseido’s e-commerce packaging options now include biodegradable bags, and internal cushionings have been replaced with recyclable honeycomb wrap, supporting both regulation compliance and consumer eco-preferences.

Indie and Regional Brands

REN Clean Skincare

REN’s “Clean to Planet” initiative uses bottles made entirely of recycled plastic, including 20% ocean-sourced plastic, and metal-free pumps to maximize recyclability. Collaborations with TerraCycle and NGO partnerships drive consumer awareness and expand the zero-waste pledge across product ranges.

Youth to the People

This brand chooses glass packaging for its luxury skincare, emphasizing infinite recyclability and product safety. Clear recycling instructions, eco-labels, and social media campaigns encourage correct disposal, closing the loop for eco-conscious consumers.

Whamisa (South Korea)

Whamisa employs plant-based labels, mono-material PET bottles, and minimal packaging, using recycled sugarcane pulp and soybean ink for labels. This approach ensures local compliance and delivers clear recyclability messaging.

Dr. Hauschka (Europe)

Dr. Hauschka has introduced new amber glass jars made with 52% recycled glass and 95% PCR plastic lids. Cardboard overwraps manufactured from recycled fiber improve recyclability and enhance packaging aesthetics without sacrificing protection.

Practical Strategies Observed

Mono-material Design: Less mixing of plastics and other materials enables easier recycling, as seen with Garnier and Shiseido.

Consumer Education: REN and Youth to the People build awareness through digital engagement, packaging labels, and disposal instructions.

Refill and Reuse: L’Oréal, Estée Lauder, and Dr. Hauschka promote refillable formats, keeping outer packaging in use longer.

Eco-labels and Transparency: Brands invest in certifications (FSC, PCR content) and visible recycling icons to build trust.

These case studies show that the path to greater circularity in beauty packaging involves large-scale innovation, partnerships, and sustained consumer engagement—all while maintaining the luxury appeal that defines the sector.

5. Consumer Insights on Recyclable Packaging

Recent survey data show over 65% of consumers now actively check product labels for recyclability before making a purchase, with Millennials and Gen Z especially likely to choose brands that lead in sustainable packaging. Younger generations are even willing to pay a premium—sometimes up to 50% more—if a product’s packaging aligns with their environmental values.

Key Insights on Consumer Behavior

Label Awareness: A full 84% of European consumers report checking on-pack instructions to guide recycling and disposal, making clear labeling one of the most influential factors in purchase decisions.

Material Preferences: Paper, glass, and mono-material plastics are favored for their perceived eco-friendliness and easy recyclability, with paper packaging trusted most for its compostability.

Generational Shifts: Nearly 60% of Millennials and 56% of Gen Z have purposefully switched to products with better sustainable packaging, driving brands to improve recycling claims and proofs.

Misunderstandings Persists: Many consumers equate “recyclable” with “eco-friendly” or “zero-impact,” despite the reality that actual recyclability depends on local recycling programs, packaging design, and material demand. Education is still crucial to clarify these terms and prevent greenwashing.

Effective Brand Communication Strategies

Brands are finding success by focusing on several communication pillars:

Clear Labeling: Symbols, concise instructions, QR codes, and reuse/recycle guides are highly effective at informing consumers and boosting brand credibility.

Digital Campaigns: Social media stories, influencer partnerships, and behind-the-scenes content help brands illustrate how packaging is recycled/reused, further connecting with values-driven audiences.

Storytelling: Sharing the journey of recycled materials, transparency in sourcing, and highlighting the positive community/environmental impact all encourage consumers to engage responsibly and build brand trust.

Third-party Certifications: Credible eco-labels (like FSC, BPI, or third-party recyclability logos) reassure savvy consumers and make claims tangible.

By combining transparent information with visually appealing design and smart storytelling, brands can educate consumers, correct misconceptions, and drive greater engagement in the circular economy. Consumer demand is aligned with responsible brand behavior and credible, actionable packaging signals.Recent surveys show that over 65% of consumers now examine product labels for recyclability before making a purchase, with Millennials and Gen Z especially likely to switch brands if offered more sustainable packaging. However, there is still prevalent confusion—many equate “recyclable” with “eco-friendly” or “zero-impact,” when actual recyclability depends on material type and local infrastructure.

Consumer Survey Trends

84% of European shoppers check on-pack recycling instructions, making recyclability the most influential factor in their purchasing choices.

Brand trust is bolstered by paper, glass, or mono-material plastics, which are easier for consumers to recycle or compost.

Millennials and Gen Z actively seek brands with genuine green packaging and are even willing to pay premiums—sometimes up to 50% more—for products meeting their values.

Misinformation is common: consumers often misunderstand “recyclable” claims, highlighting the need for clearer, verified messaging and consumer education.

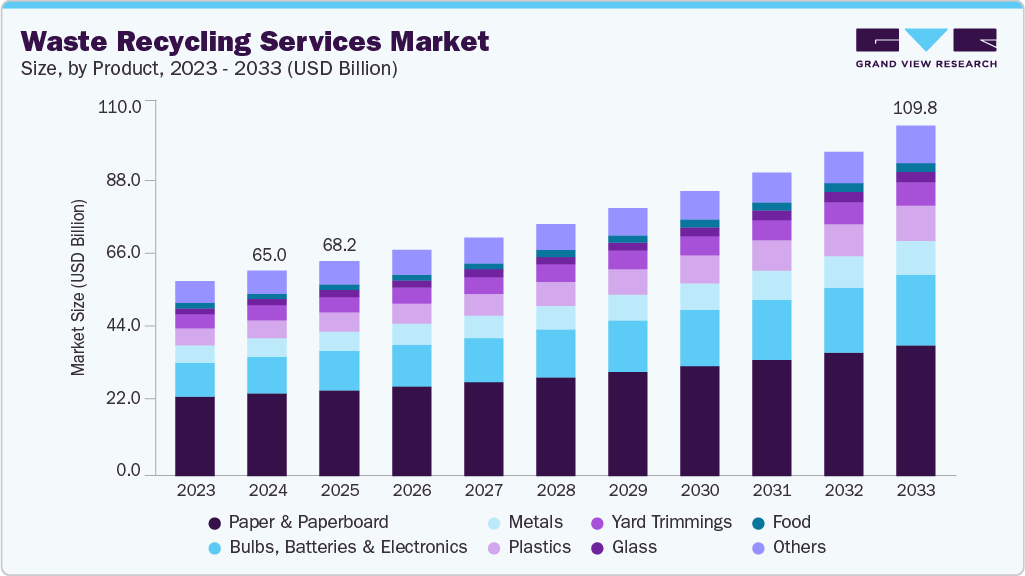

6. Cost and Supply Chain Challenges

Recyclable packaging introduces important cost and supply chain challenges, but innovations and strategic planning are helping brands respond effectively as sustainability goals become industry standards.

Cost Considerations

Recyclable packaging often comes with a price premium, particularly when high recycled content is required. Premium paper packaging, recycled plastics, and advanced biopolymers generally cost more than conventional materials, partly due to limited availability and price volatility in raw material markets. For example, rigid boxes with premium finishes can reach $5–25 per unit, while folding cartons and corrugated boxes remain more affordable but may sacrifice the high-quality feel sought in beauty products. However, as demand increases and manufacturers invest in new technologies, costs for recycled content are stabilizing, with bulk orders and scale further reducing per-unit cost.

Supply Chain Readiness

Supply chain readiness is highly variable across regions. Developed markets like Western Europe, North America, and Japan offer robust recycling infrastructure, supporting brands’ efforts to deliver fully recyclable packaging at scale. In contrast, emerging economies may struggle with consistent waste collection, sorting, and recycling, resulting in lower rates of recycled material availability. Brands must tailor their approach:

In mature markets, recycled content and advanced sorting are feasible, allowing mono-material solutions to succeed.

In regions lacking infrastructure, brands face accusations of greenwashing if packaging is “technically” recyclable but likely to be landfilled.

Global supply chains must adapt through stronger collaboration with recycling facilities, local governments, and technology partners—sometimes requiring alternate packaging designs for specific markets.

Mass Production Considerations

Maintaining quality and consistency in mass production is a persistent challenge. Using recycled materials can lead to variability in color, texture, and structural integrity; recycled paper fibers are often shorter and weaker, and recycled plastics may differ from virgin grades, potentially affecting packaging appearance and durability. Othilapak and other leading suppliers address this with strict quality control, digital watermarks, and precision processing, assuring that recycled packaging consistently meets brand standards.

Industry Response

Technology and supplier collaboration are boosting capacity, enabling stable supply and improved material characteristics for recycled content.

New standards for design-for-recycling drive efficiency, support effective sourcing, and maximize usable waste streams, especially in high-volume production.

Brands increasingly invest in bulk orders, circular supply chain partnerships, and localized material sourcing to improve cost and reliability.

Balancing cost and sustainability requires continuous innovation and localized strategy, but ongoing advances are making it ever more feasible for brands to meet their recyclable packaging goals without compromising market appeal or operational efficiency.

7. Conclusion

Cosmetic recyclable packaging is now fundamental to brand success, regulatory compliance, and meeting consumer expectations. As regulations tighten worldwide and sustainability emerges as a top priority—driven by consumers, investors, and ESG (Environmental, Social, Governance) frameworks—brands have no choice but to embrace recyclable packaging as a business standard and not a mere marketing option.

Othilapak streamlines this transition for clients. With comprehensive services that span global compliance expertise, material selection, innovative design, and scalable implementation, Othilapak empowers beauty brands to deliver packaging that is visually striking, functional, and meets evolving sustainability requirements. The team’s focus on harmonizing aesthetics, technical recyclability, and regulatory adherence ensures clients don’t have to choose between beauty and responsibility.

For brands seeking to navigate recyclable packaging—balancing regulatory demands, consumer loyalty, and operational scalability—Othilapak serves as the ideal partner. Reach out today to collaborate on creative, compliant, and sustainable packaging solutions that secure consumer trust, satisfy regulations, and bolster brand value in a competitive marketplace.