Quote

Recyclable Packaging for a Sustainable Future

Returnable packaging is a sustainable system in which containers and packaging are designed for multiple use cycles—after use, customers can return empty packaging to the brand for cleaning, refilling, and reuse, rather than discarding it. This approach significantly reduces single-use plastic and packaging waste, helping decrease landfill contributions and the overall carbon footprint in the beauty and cosmetics industry.

While returnable packaging offers environmental and economic advantages—such as cost savings for consumers on refills and reduced need for new material production—its implementation does bring logistical and design challenges. Brands must establish efficient systems for collecting, sanitizing, and redistributing packaging, as well as educate consumers on how to participate effectively in these programs. Despite these hurdles, the movement toward returnable packaging is gathering momentum and holds immense promise for transforming the beauty industry into a more sustainable and circular sector.

Recyclable Packaging

The Role of Recyclable Materials in Cosmetic Packaging

Eco-friendly cosmetic packaging harnesses materials like bamboo, glass, PET/HDPE plastics, and aluminum to cut waste and lower environmental impact. These materials are chosen for being recyclable, safe for products, and appealing to sustainability-minded consumers.

Othilapak’s Recyclable Packaging Solutions

Othilapak’s recyclable packaging uses premium sustainable materials to protect products and reduce waste, allowing brands to meet both luxury and environmental goals.

Bamboo bottles and jars combine strength with elegance, supporting luxury and natural brand positioning. Bamboo’s antimicrobial “bamboo kun” agent helps extend product shelf life and maintain hygiene, which is critical for creams, oils, and sensitive formulas. Its rapid renewability and natural biodegradability allow brands to reduce their carbon footprint, showcase sustainable values, and appeal to eco-conscious markets. Custom finishes and hybrid designs—combining bamboo with glass or aluminum—provide even greater design flexibility and elevated shelf appeal.

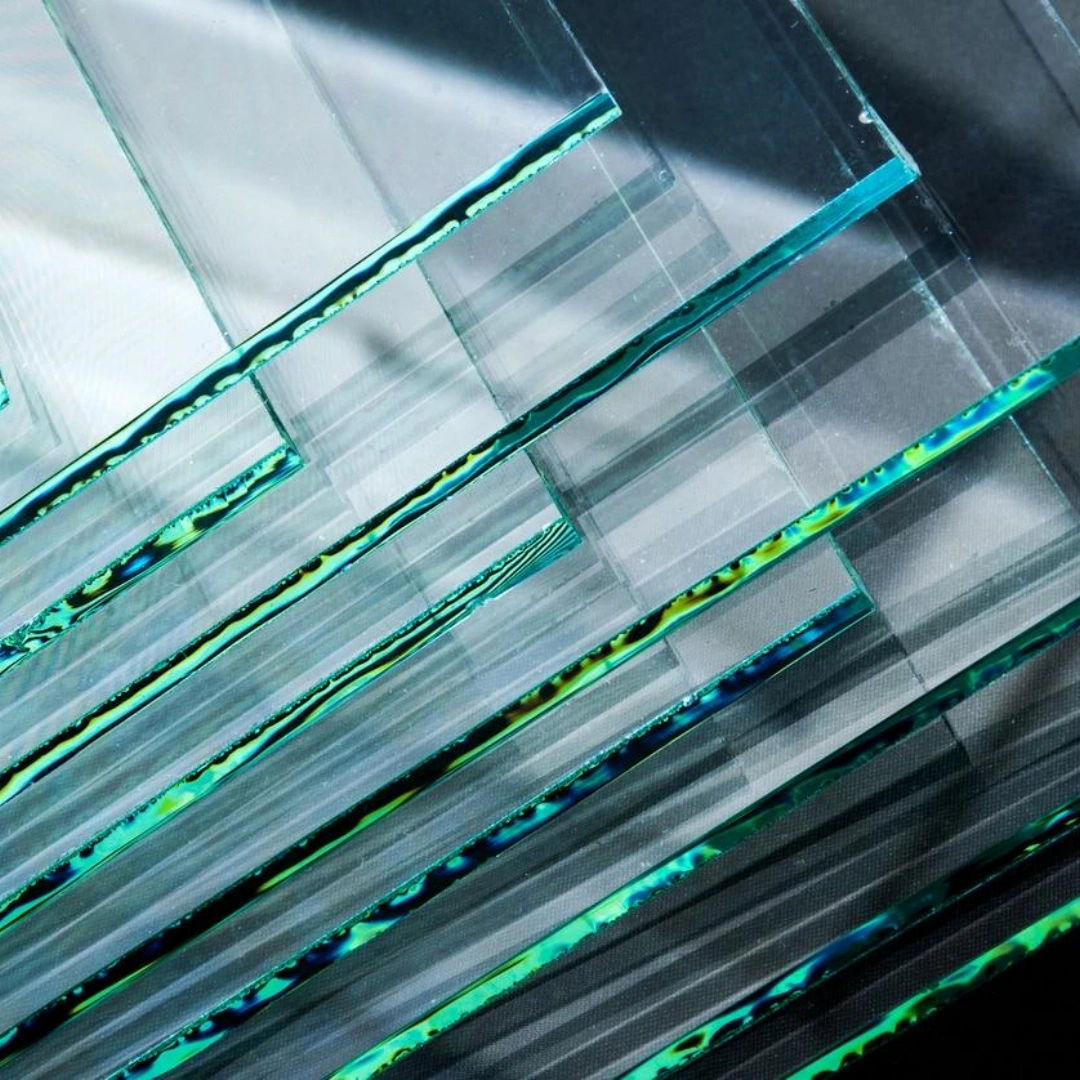

Glass containers offered by Othilapak preserve formula purity, thanks to their inert, non-reactive qualities. Glass packaging enables sophisticated branding with options for custom shapes, colors, screen printing, or engravings, and helps products stand out in high-end retail environments. Glass is fully recyclable, making it a responsible long-term choice; when paired with bamboo exteriors, brands enjoy enhanced durability and eco-elegance without sacrificing clarity or quality.

PET jars’ excellent resistance to breakage and good barrier properties protect formulations from leaks, contamination, or spoilage. Their wide opening makes them ideal for thick products, and PET’s clarity offers attractive product visibility to customers. PET is globally recyclable and can be sourced as post-consumer recycled (PCR) material, improving sustainability metrics without compromising on performance or safety.

HDPE packaging is highly valued for impact resistance, which ensures safe transport and storage for daily-use items such as lotions and shampoos. The flip-top cap enables precise product dispensing, reducing waste and unintentional spills. HDPE is among the most widely recycled plastics, contributing to sustainable supply chains—a strong selling point for both private label and branded personal care products.

Aluminum closures provide tamper-evident, airtight sealing that is crucial for product freshness and integrity, especially in cosmetics prone to oxidation. Aluminum’s light weight and endless recyclability lower shipping-related emissions and further the environmental advantages of the package. Polished or brushed aluminum enhances aesthetic value, and paired with bamboo or glass, creates premium visual impact for gift sets and signature launches.

Recycle.

Reuse.

Repeat.

For packaging that creates an endless, sustainable loop.

FAQs: Recyclable Cosmetics Packaging

Can all cosmetic packaging be recycled?

Not all cosmetic packaging is recyclable. Plastic bottles, jars, and some tubes are widely accepted, but many makeup items (like compacts, pumps, or multi-material containers) may not be recyclable in curbside programs. Always check local guidelines and look for recycling symbols on the packaging.

Do I need to clean out cosmetic containers before recycling?

Yes, cosmetic packaging should be emptied and rinsed to remove product residues before recycling. This helps prevent contamination of the recycling stream and ensures items are actually processed.

Why aren’t all beauty containers accepted in curbside recycling?

Some beauty packaging is made from mixed materials, small sizes, or specialty plastics that are not widely accepted. Local recycling rules and the limits of sorting equipment can exclude these from curbside programs, so it’s best to confirm locally or use specialty collection programs.

How can brands help make their cosmetic packaging more recyclable?

Using single-material designs, clear recycling icons, larger sizes, and fewer decorative elements all help. Brands can also partner with recycling programs to educate customers and increase genuine recycling rates.

Is recyclable packaging cost-effective?

While initial costs are sometimes higher, returnable solutions save money over time by reducing the need for new packaging, lowering disposal fees, and streamlining logistics—especially at scale.